An Efficient Substrate Lift-Off Method

A substrate, high-efficiency technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as easy damage of epitaxial structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

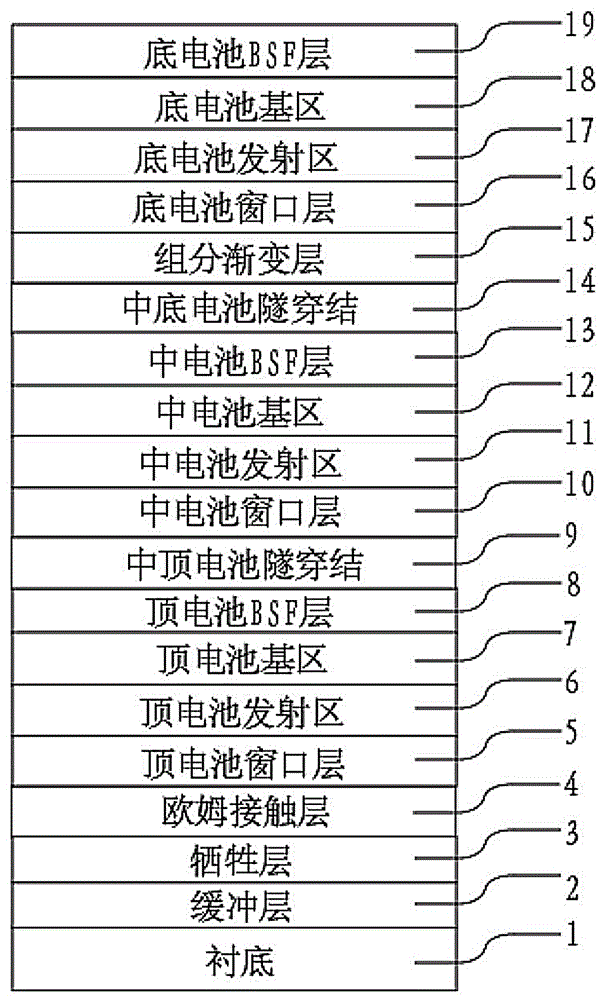

[0041] like figure 1 As shown, the present invention discloses a solar cell epitaxial structure with a substrate that can be peeled off. On the surface of the substrate 1 from bottom to top, epitaxial buffer layer 2, sacrificial layer 3, ohmic contact layer 4, top cell window layer 5, Top cell emission region 6, top cell base region 7, top cell BSF layer 8, middle top cell tunnel junction 9, middle cell window layer 10, middle cell emission region 11, middle cell base region 12, middle cell BSF layer 13, Middle bottom cell tunnel junction 14 , composition graded layer 15 , bottom cell window layer 16 , bottom cell emitter region 17 , bottom cell base region 18 and bottom cell BSF layer 19 .

[0042] The substrate 1 is a 4-inch GaAs substrate with a thickness of 400 μm. The material of the buffer layer 2 is GaAs III-V compound with a thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com