Pneumatic radial tire

一种子午线轮胎、胎圈的技术,应用在充气轮胎的增强层、特殊轮胎、轮胎零部件等方向,能够解决高速耐久性降低、带束层环箍效果变弱等问题,达到高速耐久性提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

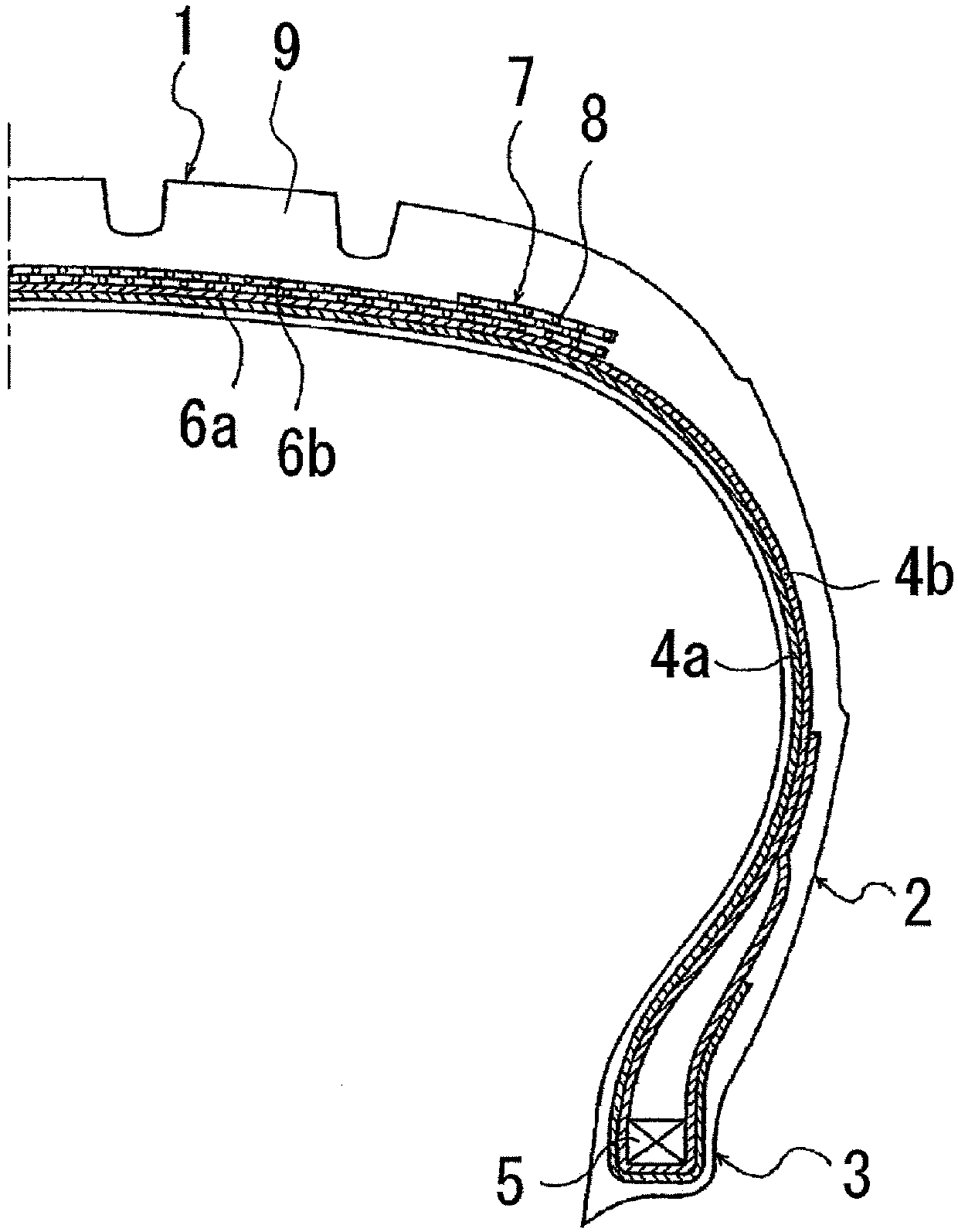

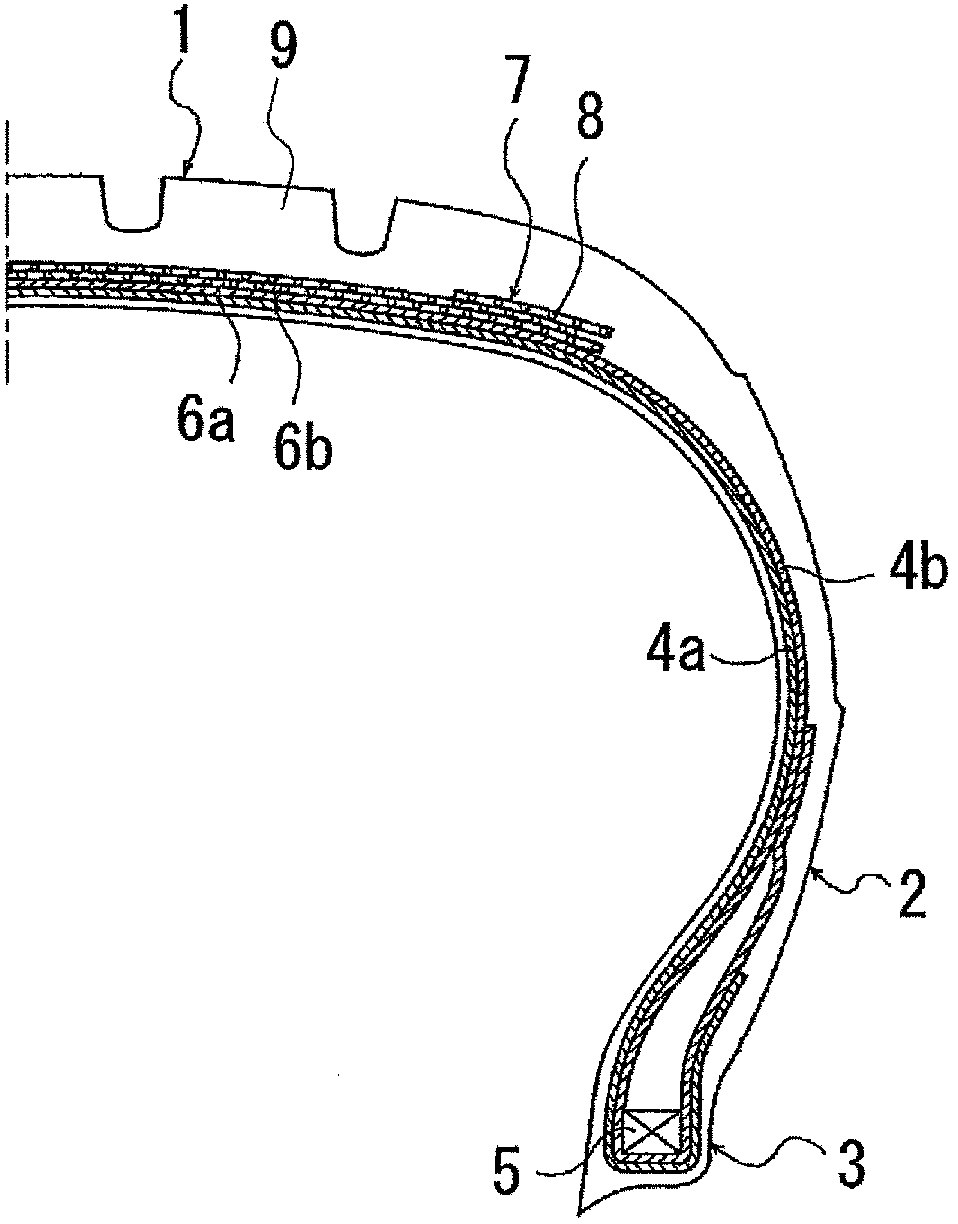

Image

Examples

example

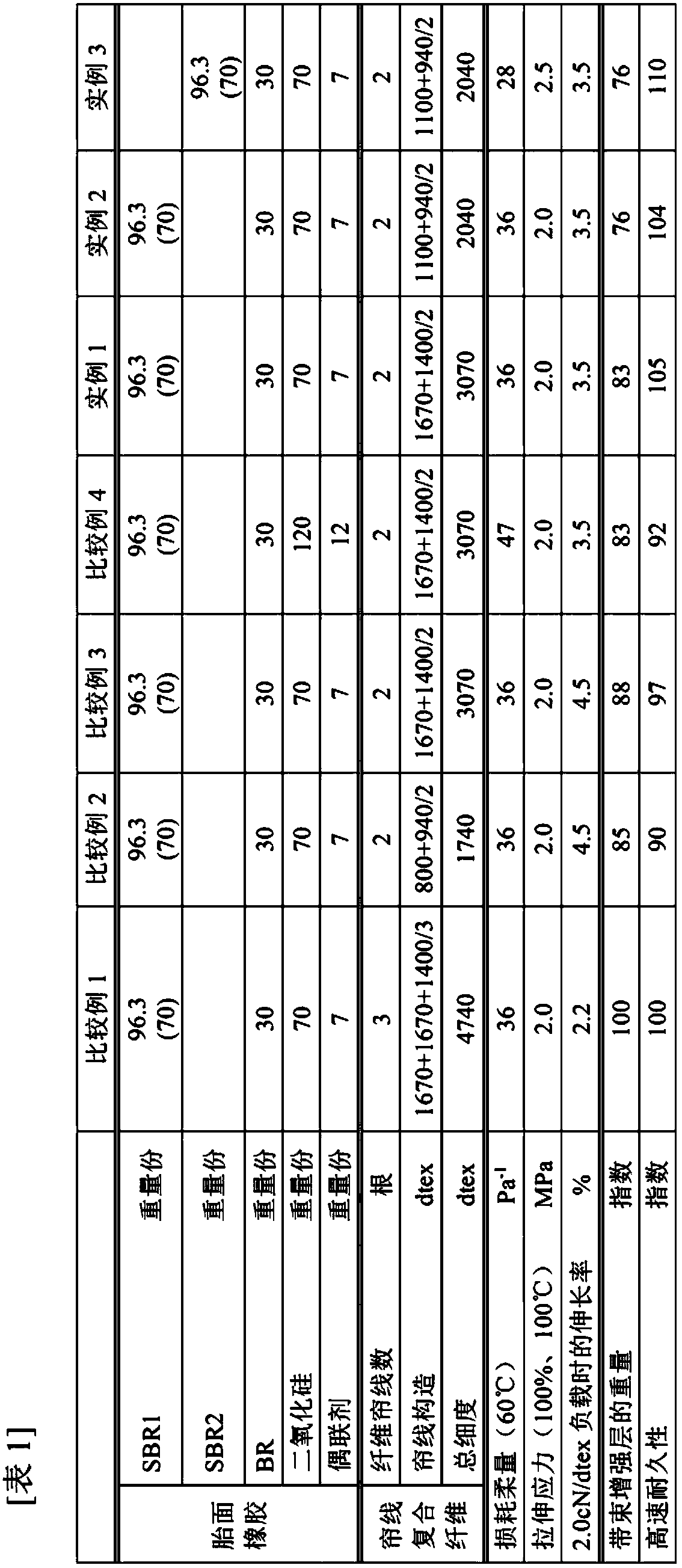

[0041] Using the compounding ingredients shown in Table 2 as the general compounding, using a 1.7L closed-type Banbury mixer, the rubber compositions for treads (Examples 1-3, Comparative Example 1 ~4) The components other than the sulfur and the vulcanization accelerator are kneaded, and after a predetermined period of time, they are discharged from the internal mixer and cooled to room temperature. This was put into a 1.7 L closed-type Banbury mixer, and sulfur and a vulcanization accelerator were added and mixed to prepare a rubber composition for treads. It should be noted that in the diene rubber (SBR1, SBR2) column in Table 1, in addition to the compounding amount of the product, the net compounding amount of SBR excluding the oil-extending component is also described in parentheses. In addition, the compounding quantity of the compounding agent shown in Table 2 is represented by weight part with respect to 100 weight part of diene rubbers shown in Table 1.

[0042] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com