Quartz cavity cleaning device and cleaning method

A technology for cleaning devices and quartz chambers, applied to cleaning methods and appliances, chemical instruments and methods, and cleaning hollow objects, etc., can solve problems such as external erosion of quartz chambers, reduce usage, save costs, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

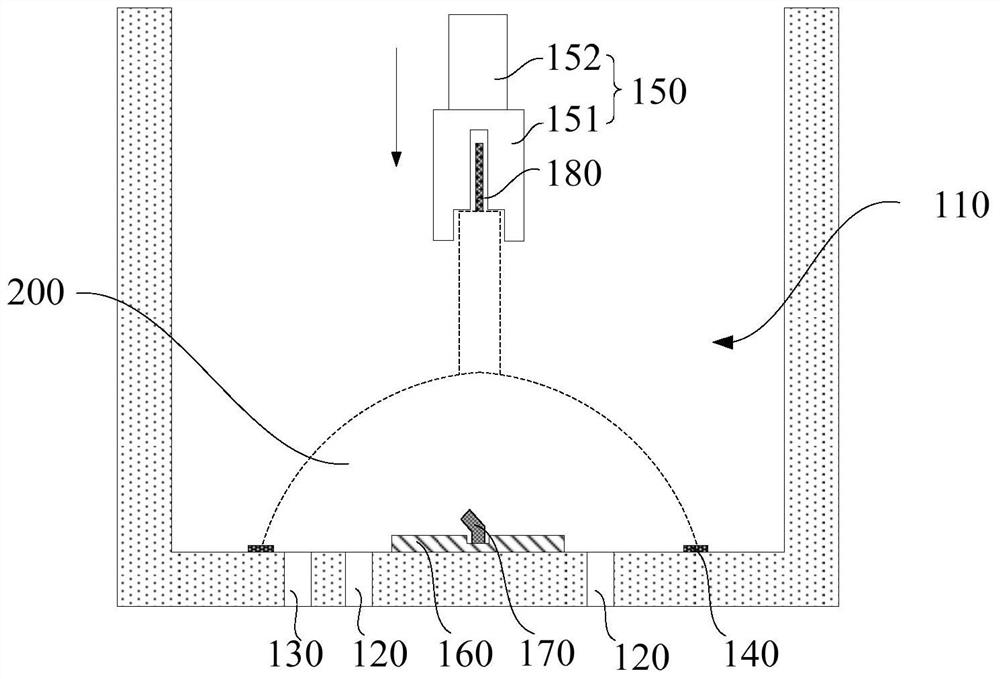

[0041] As described in the background technology, when the cleaning device in the prior art is used to clean the quartz cavity through the immersion cleaning method, although the purpose of cleaning the inside of the quartz cavity can be achieved, at the same time, the cleaning liquid will also affect the quartz cavity. The outside of the body will cause erosion, which will greatly shorten the service life of the quartz cavity. Therefore, the present invention improves the cleaning device to avoid the problem that the cleaning liquid corrodes the outside of the quartz cavity during the cleaning process, so as to prolong the service life of the quartz cavity.

[0042] The cleaning device for the quartz cavity provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com