Carrying device of special-shaped terminal mould casting piece

A special-shaped terminal and handling device technology, applied in the direction of coating, etc., can solve the problems of prolonged product production cycle, terminal falling into the gap of the mold, and increase product cost, so as to reduce the number of mold maintenance and safety hazards, shorten the production cycle, The effect of reducing economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

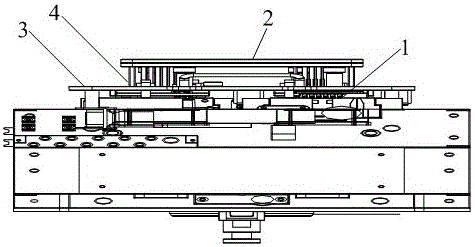

[0021] Such as figure 1 As shown, the handling device of the special-shaped terminal mold casting of the present invention includes a special-shaped terminal swing-in mechanism 1, a handling mechanism 2, a clamping mechanism 3, and an unloading mechanism 4. The special-shaped terminal swing-in mechanism 1 is located below the clamping mechanism 3. The mechanism 2 is located above the unloading mechanism 4 , the clamping mechanism 3 is located between the special-shaped terminal swing-in mechanism 1 and the unloading mechanism 4 , and the unloading mechanism 4 is located between the conveying mechanism 2 and the special-shaped terminal swing-in mechanism 1 .

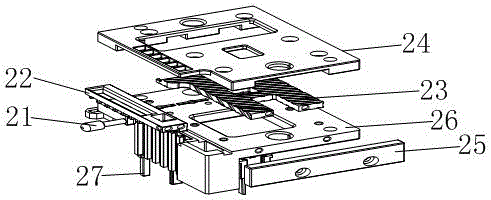

[0022] Such as figure 2 As shown, the special-shaped terminal swing-in mechanism includes a slider puller 21, a first terminal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com