Carrier structure of drip chamber assembly

A carrier and component technology, which is applied in the production and assembly device of infusion tube catheters and the carrier structure field of dropping funnel components, can solve the problems of inability to assemble, inapplicable transfer and assembly, etc., and achieves easy clamping, convenient and fast and Accurate placement, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

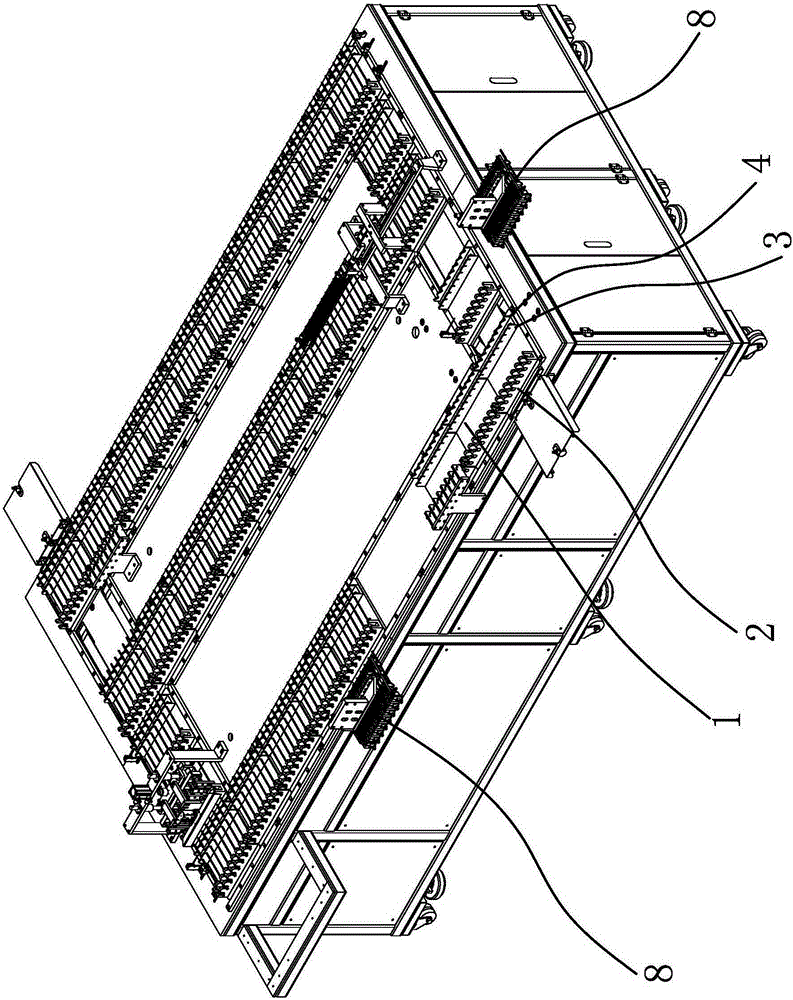

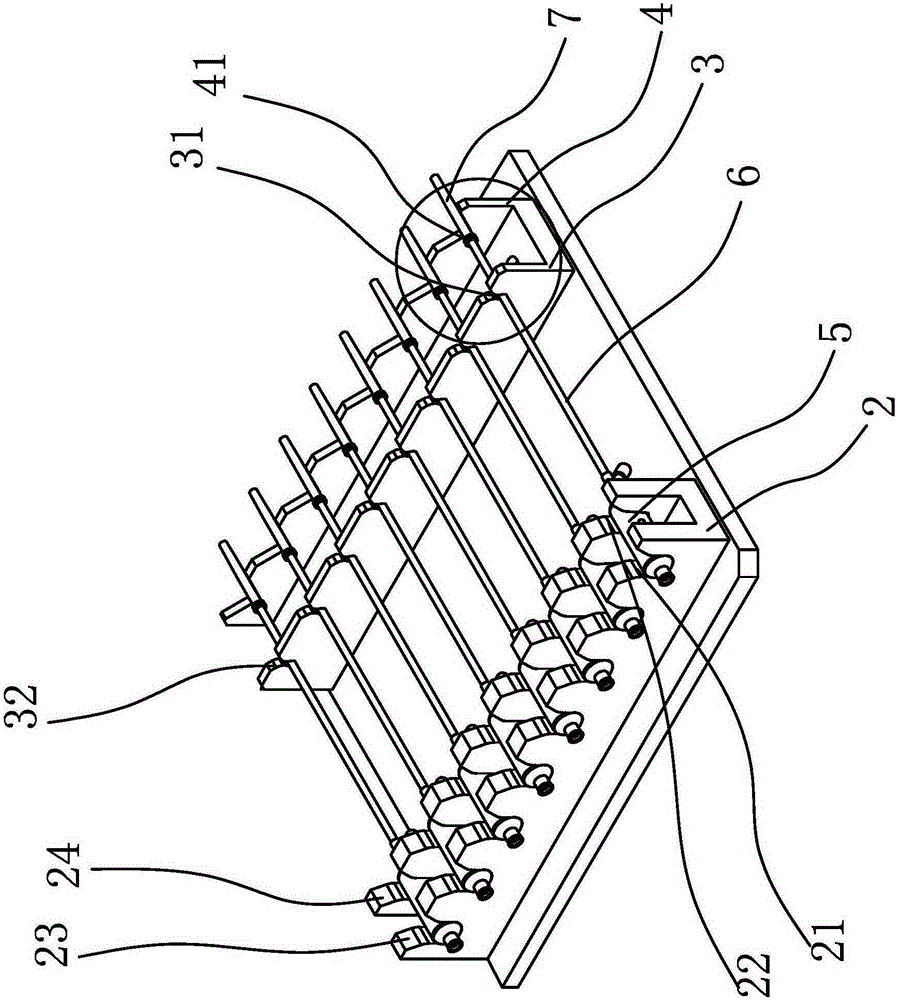

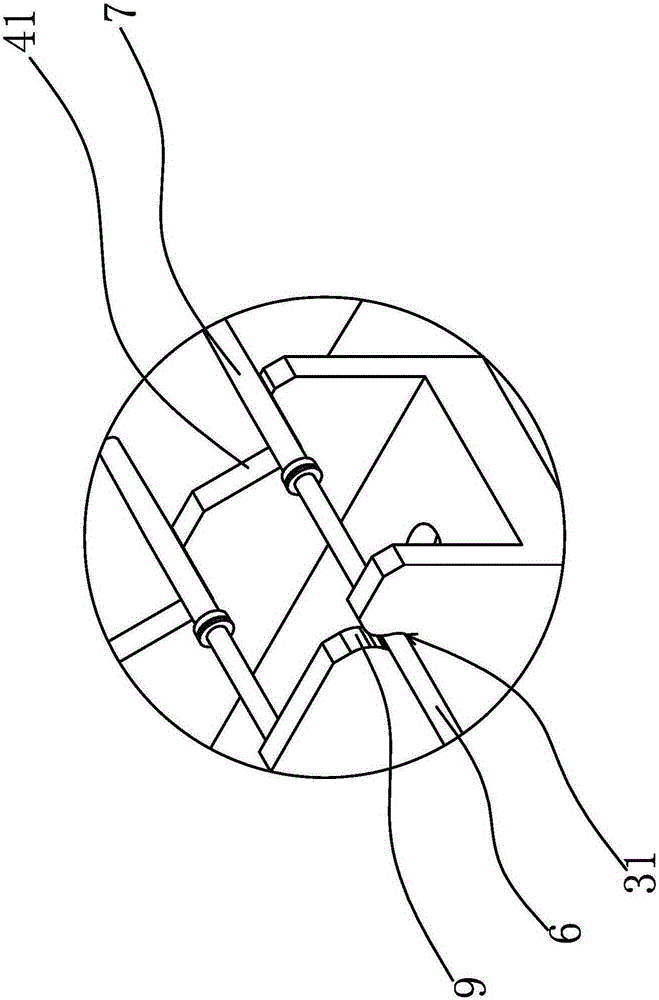

[0026] Such as figure 1 , figure 2 and image 3 As shown, the vehicle includes a seat body 1, on which a drip funnel fixing seat 2, a conduit support plate 3 and a pin support plate 4 are sequentially fixed, and on the drip funnel fixing seat 2, there are respectively spaced holes for clamping drops. Notch one 21 and notch two 22 at both ends of the bucket 5, a bayonet 31 for clamping the conduit 6 is provided on the conduit support plate 3, an opening 41 for placing the contact pin 7 is provided on the pin support plate 4, and the groove Mouth one 21, notch two 22, bayonet notch 31 and opening 41 are located on the same straight line; The two side walls of one 21 obliquely extend to the guide surface one 23 on both si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com