Universal steel-plastic composite pipe piston pressure test device

A steel-plastic composite pipe and piston-type technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of time-consuming, cumbersome, loose pressing blocks, etc., to avoid single repeated installation, avoid leakage, and seal good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

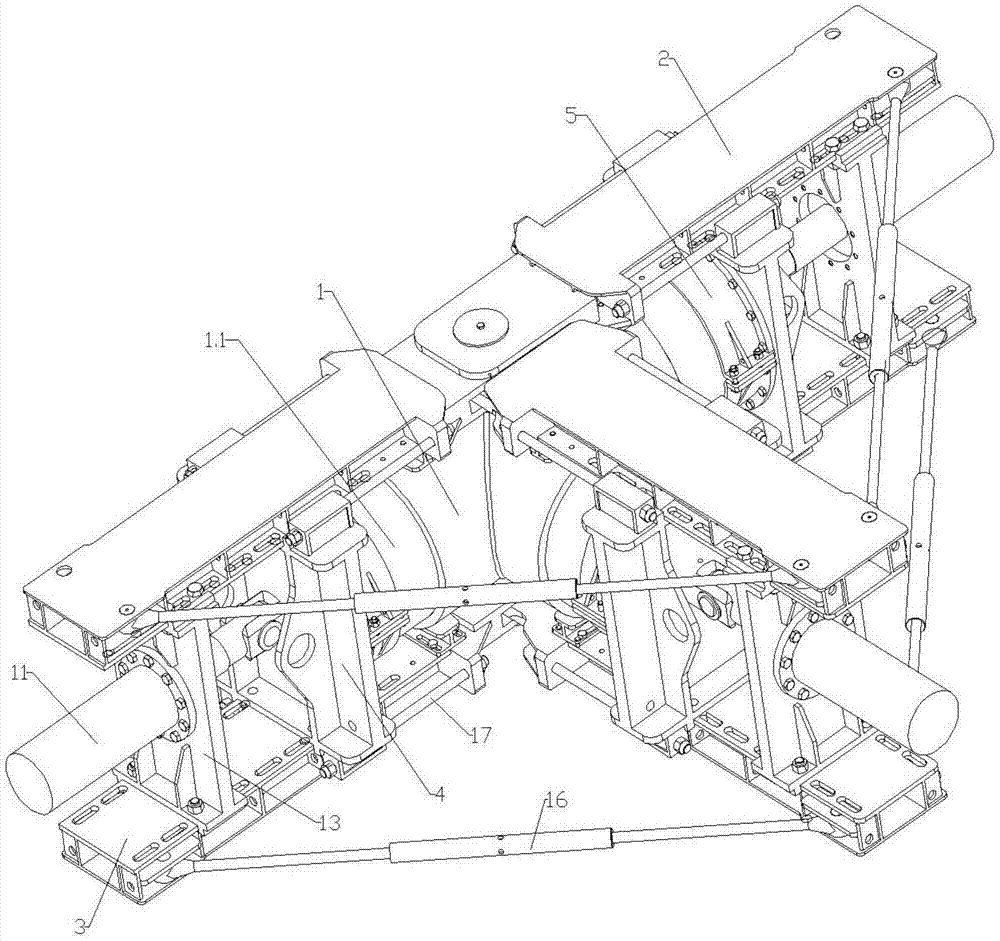

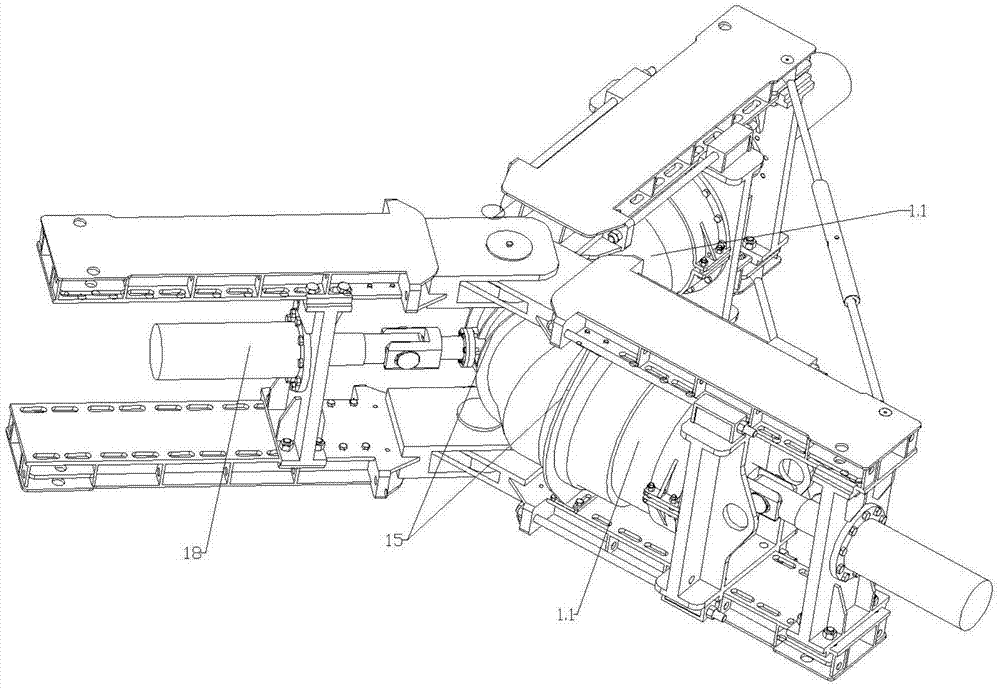

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

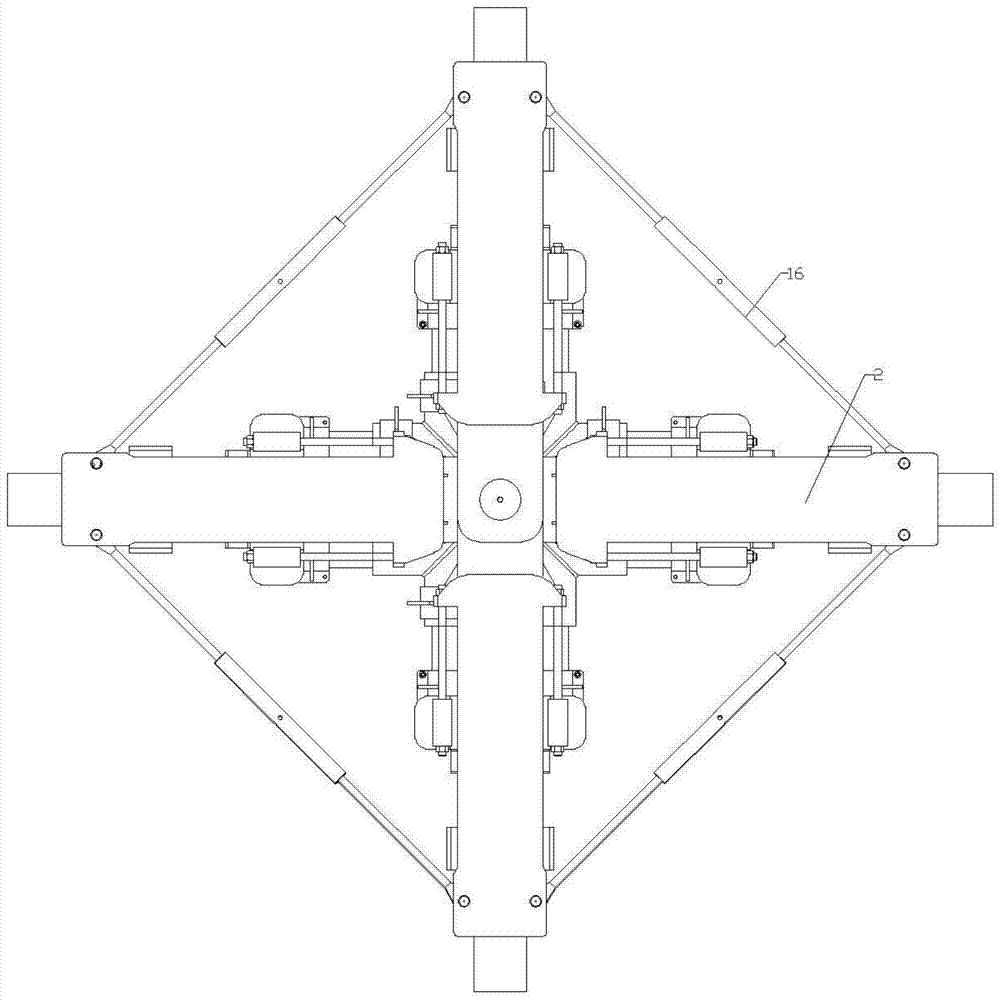

[0026] As shown in the figure, the general-purpose steel-plastic composite pipe piston pressure test device of the present invention includes an upper beam 2 arranged above each pipe section 1.1 of the steel-plastic composite pipe 1 and a lower beam arranged below each pipe section 1.1 of the steel-plastic composite pipe 1 3. Plugging the ports 1.1 of each pipe section 1 of the steel-plastic composite pipe 1 to achieve zero leakage. Institutions, and the industry is accustomed to call the piston pressure test mechanism. The upper beam 2 is hinged on the same upper fulcrum, and the lower beam 3 is hinged on the same lower fulcrum.

[0027] The number of upper beams and lower beams can be set according to the number of steel-plastic composite pipe sections: for straight-line pipes, two upper beams with an included angle of 180 degrees and two lower beams with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com