Carrying robot

A technology for handling robots and clutches, applied in the field of handling robots, can solve problems such as affecting the overall efficiency, fixed rotation angle, and large differences in implementation forms, and achieve the effect of improving handling efficiency and having a reliable and stable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

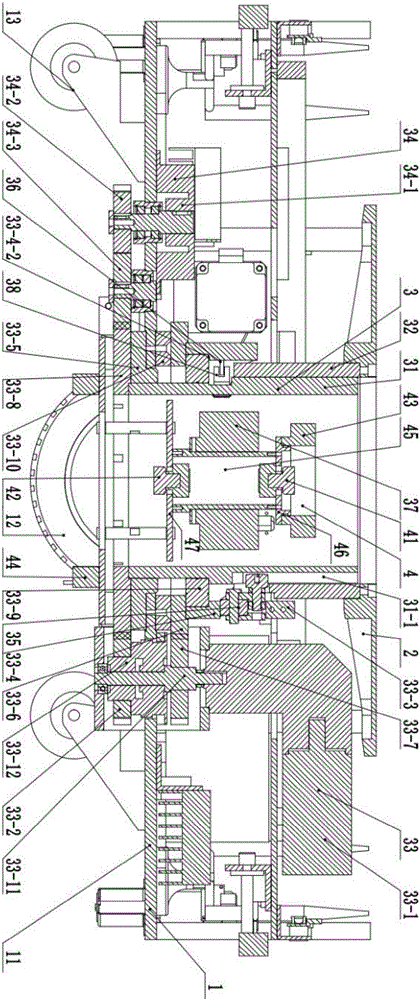

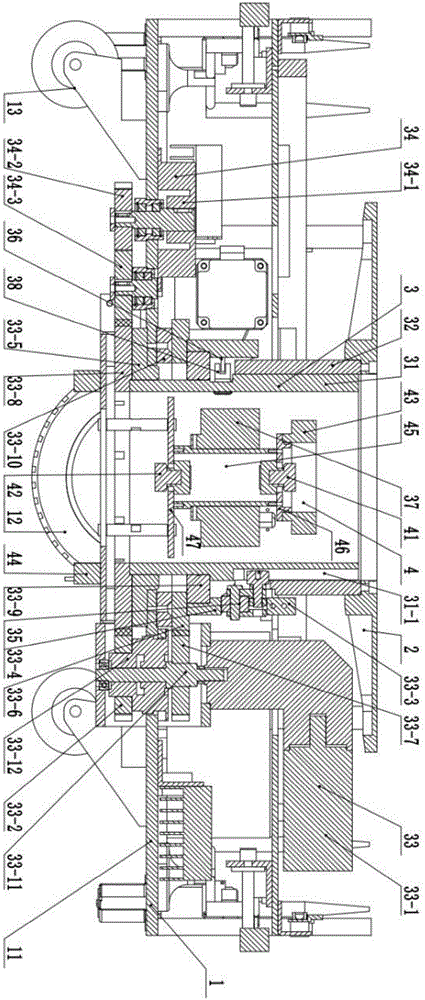

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

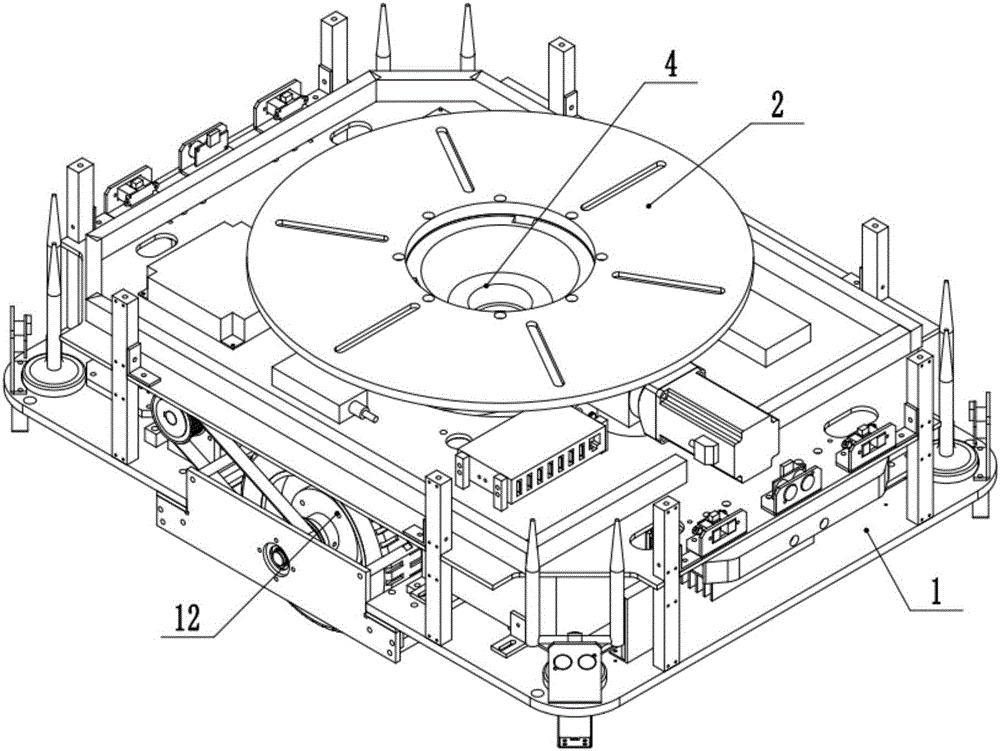

[0023] as attached figure 1 - attached image 3 The conveying robot shown includes a vehicle body 1 , a pallet 2 , a lifting and rotating unit 3 that drives the pallet 2 to lift and rotate relative to the vehicle body 1 , and a camera assembly 4 .

[0024] The vehicle body 1 includes a base plate 11 and two driving wheels 12 arranged on symmetrical sides of the base plate 11 , and a plurality of driven wheels 13 are symmetrically arranged on the base plate 11 . Specifically, the driving wheels 12 are arranged on both sides of the base plate 11 in the width direction and at the middle position in the length direction of the base plate 11 , and there are four driven wheels 13 , which are arranged symmetrically at the four corners of the base plate 11 . The two driving wheels 13 can rotate independently, so that the car body 1 can not only move forward and backward, but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com