Constant-temperature water outlet structure special for gas water heater

A technology of gas water heater and water outlet structure, which is applied to fluid heaters, lighting and heating equipment, multi-way valves, etc. Hot and cold, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

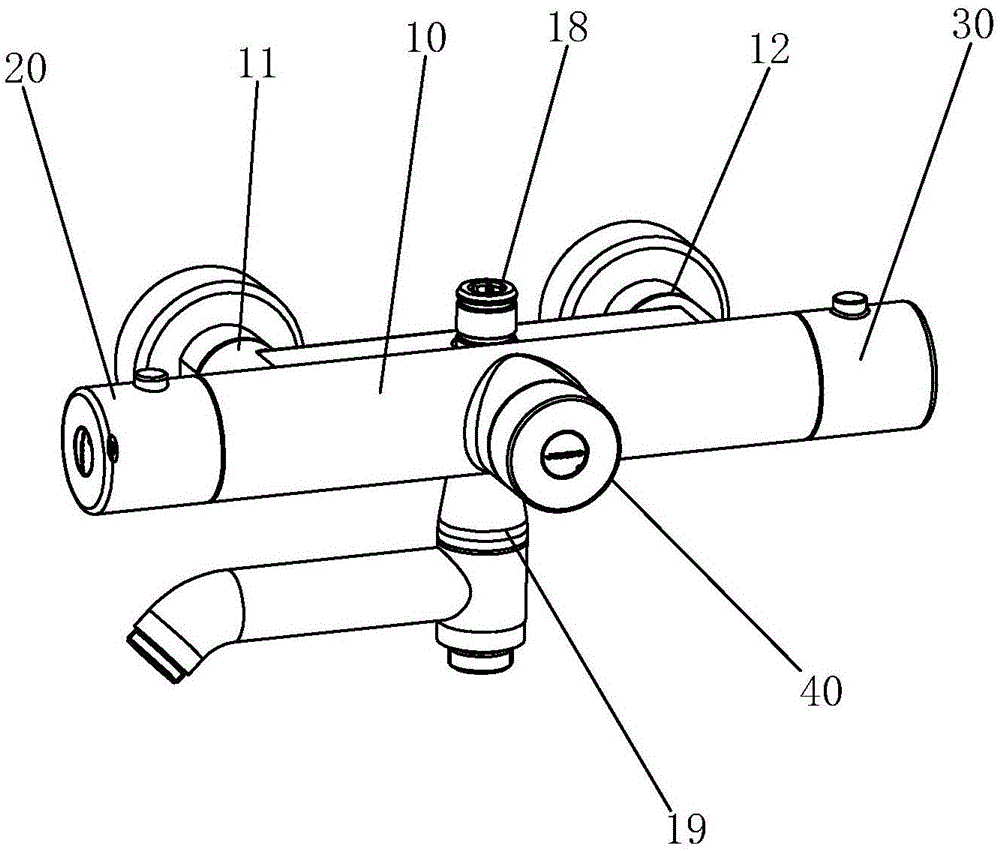

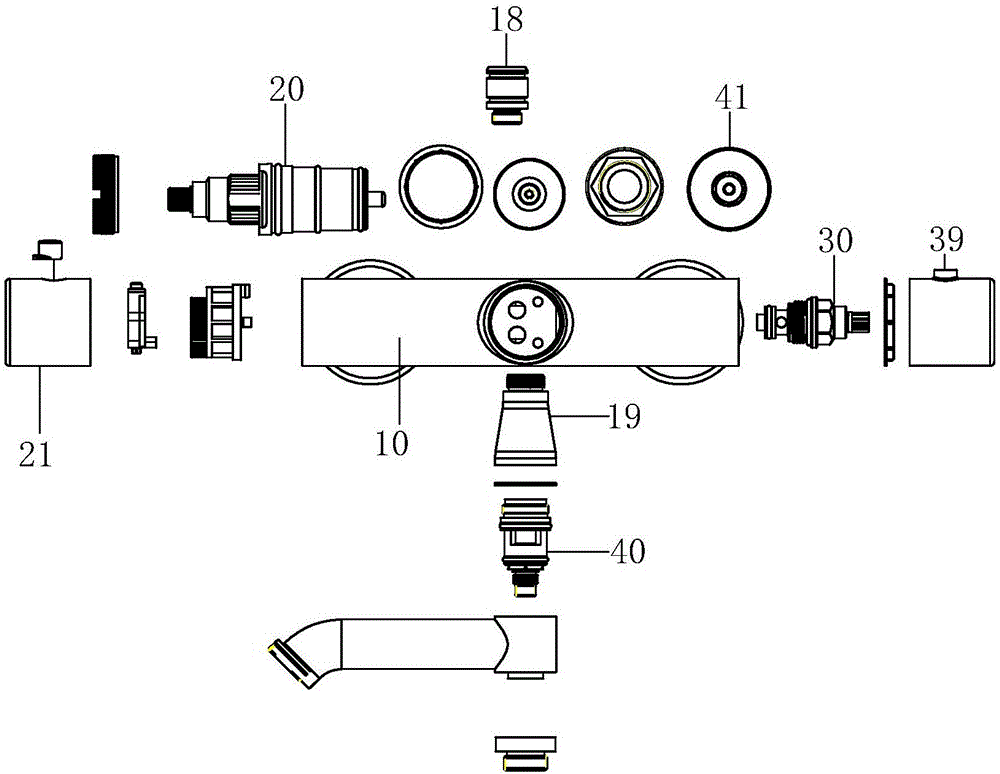

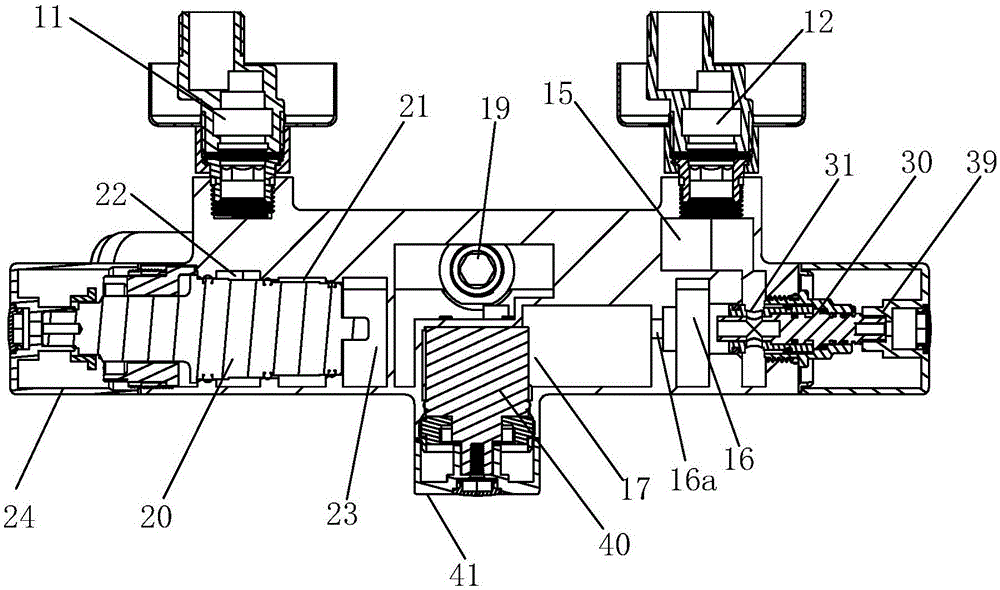

[0039] refer to Figure 1 to Figure 5 , in this embodiment, the regulating spool adopts a switch spool, which is provided with a water inlet 31 and a water outlet 32, the water inlet 31 communicates with the secondary cold water passage 15, and the water outlet 32 communicates with the first constant temperature water passage 16, A small hole 16a is provided between the first constant temperature water channel 16 and the second constant temperature water channel 17 to realize the communication between the two. By adjusting the second handwheel 39, the opening of the water inlet 31 can be adjusted, including half-open, fully open and closed, so as to switch between different gear positions.

[0040] In this embodiment, the regulating spool can be set to three gears, namely spring and autumn gears, summer gear and winter gear, and the corresponding opening degrees of the water inlet 31 are half open, fully open and closed. The specific working principle is as follows:

[004...

Embodiment 2

[0046] refer to Figure 6 to Figure 11 , in this embodiment, the regulating spool includes a switching spool and a water mixing module 34 . The switching valve core is provided with a water inlet 31 and two water outlets 32 , and the water inlet 31 communicates with the secondary cold water channel 15 . The water mixing module 34 is fixed on one end of the switch valve core, and is provided with two water mixing channels, which are respectively a normal pressure water mixing channel 35 and a pressurized water mixing channel 36, and one end of the two water mixing channels is connected to the two water outlets of the switching valve core. 32 are communicated one by one, and the other end communicates with the second constant temperature water channel 17, and the water mixing module 34 is provided with a gap 37 communicating with the first constant temperature water channel 16, and the gap 37 communicates with the two mixing water channels.

[0047] Wherein, the pressurized wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com