Water purifier and water path system thereof

A technology of water system and water purifier, which is applied in water/sewage treatment, heating water/sewage treatment, water/sewage treatment equipment, etc. The effect of ensuring the flow of hot water, improving the convenience of use and improving the response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

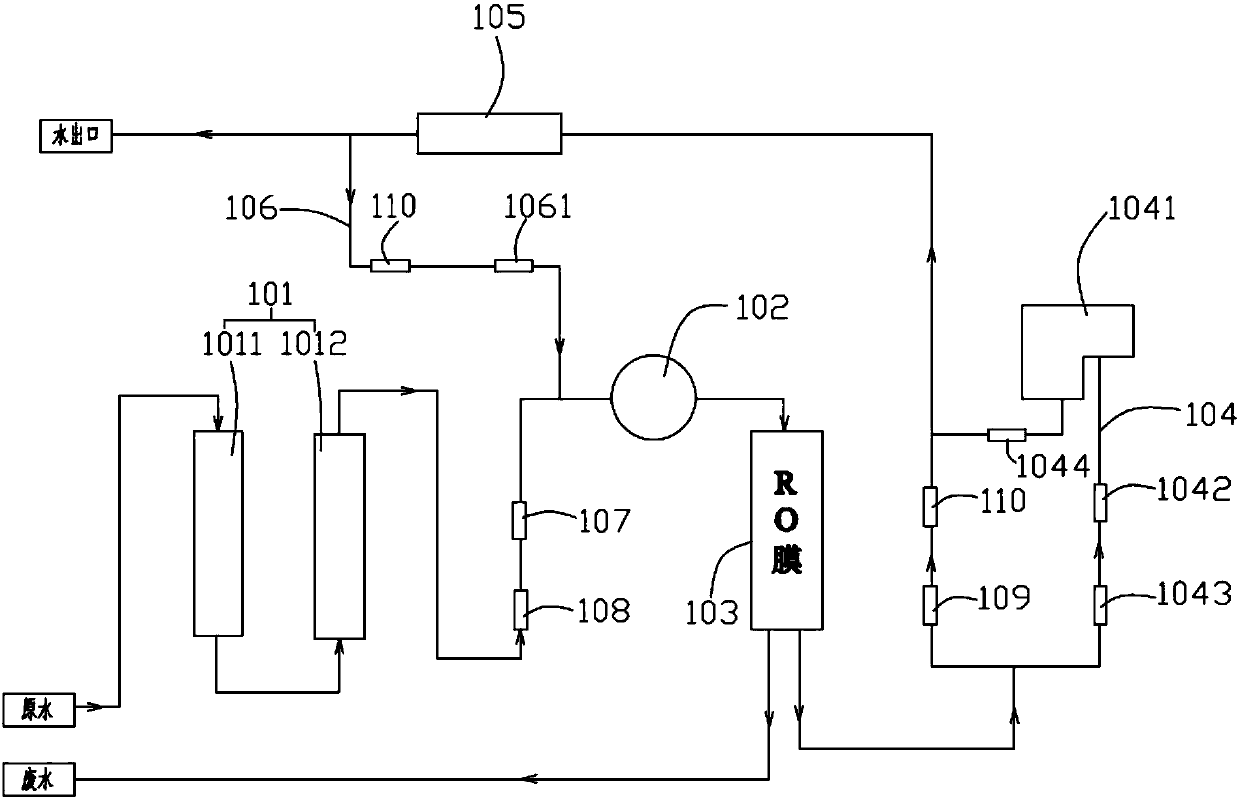

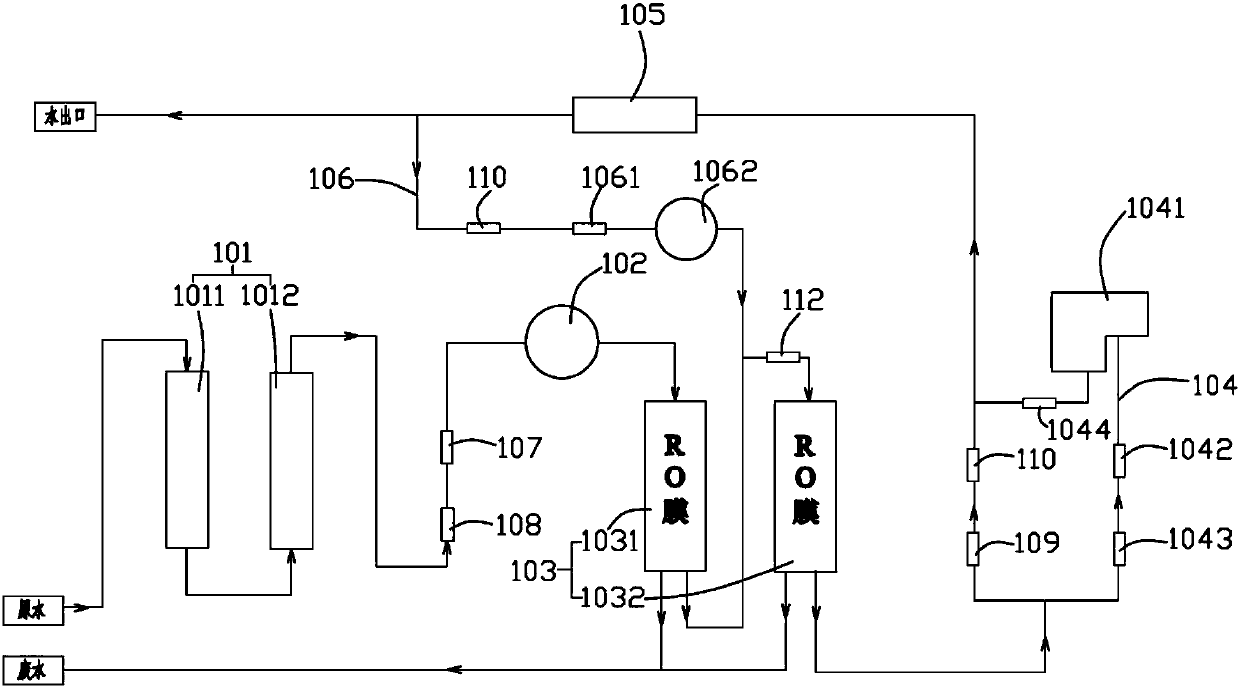

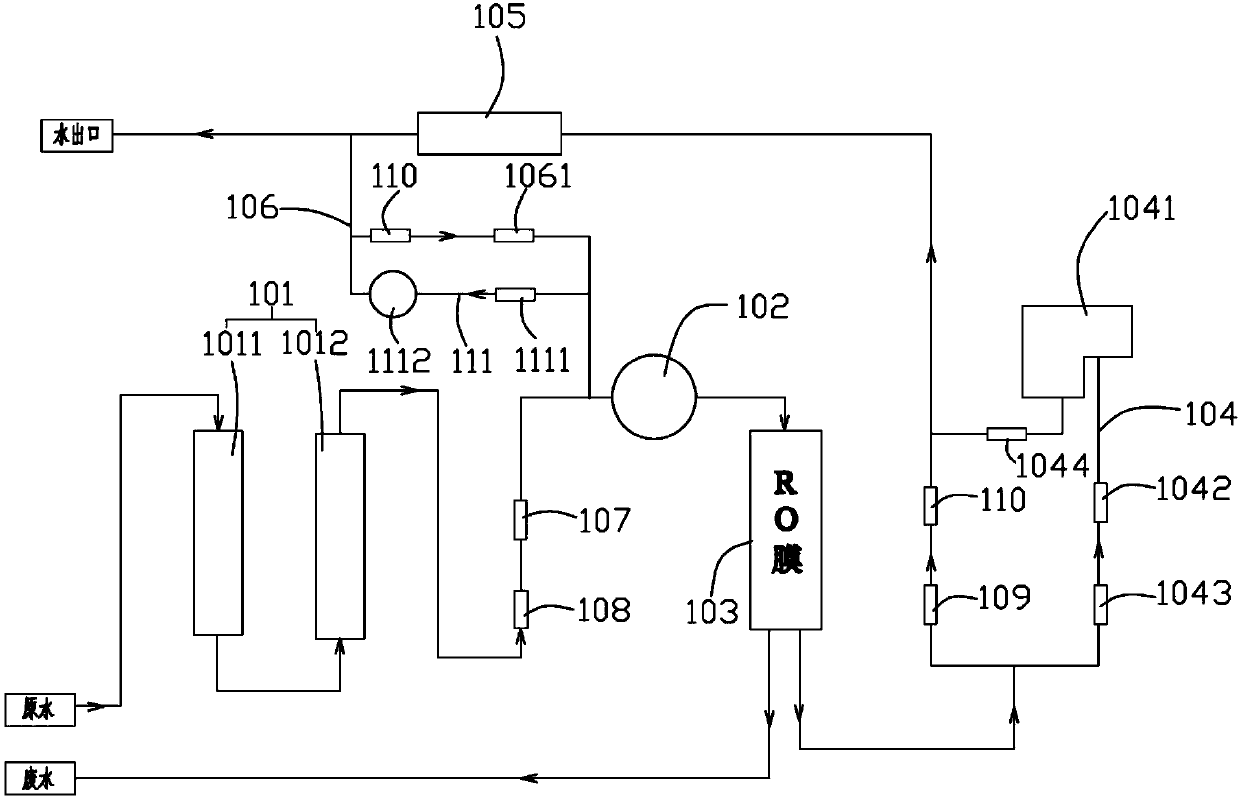

[0033] Such as Figure 1-Figure 4 , the embodiment of the present invention provides a pure water machine waterway control system, including a water supply pipeline connecting the raw water source and the water outlet of the pure water machine, and a purification mechanism and a heating mechanism 105 are sequentially arranged on the water supply pipeline along the water supply direction. A preheating flow path 104 and an emptying flow path 106 are bypassed on the water supply pipeline; both ends of the preheating flow path 104 are bypassed between the purification mechanism and the heating mechanism 105, and the water supply pipe A first control valve 109 is provided between the two ends of the preheating flow path 104 on the road, and a second control valve 1042 and a preheating tank 1041 with a built-in preheating unit are arranged on the preheating flow path 104; The inlet end of the emptying flow path 106 is connected between the heating mechanism 105 and the water outlet ...

Embodiment approach

[0043] (1) if figure 1 , as one of the feasible embodiments, the outlet end of the emptying flow path 106 is connected to the water supply pipe body between the pre-filter unit 101 and the reverse osmosis unit 103 . Further, a water inlet control valve 107 may be provided on the water supply pipe body between the pre-filter unit 101 and the first booster pump 102 . The emptying flow path 106 is preferably bypassed on the water supply pipe body between the pre-filter unit 101 and the first booster pump 102; of course, it can also be bypassed between the first booster pump 102 and the reverse osmosis unit 103 On the water supply pipe body, it is necessary to further set a power pump on the emptying flow path 106 .

[0044] When maintaining the reverse osmosis membrane, close the water inlet control valve 107, the above-mentioned first control valve 109 and the second control valve 1042, open the emptying valve 1061 and the first booster pump 102, the reverse osmosis membrane ca...

Embodiment 2

[0054] Such as Figure 5 , the embodiment of the present invention provides a pure water machine waterway system, including the raw water pipeline 201 and the raw water treatment pipeline, wherein the raw water treatment pipeline can adopt the pure water machine waterway control system provided in the first embodiment above, of course, The existing conventional pure water machine raw water treatment method can also be used, and the specific structure is omitted here. In other words, this embodiment can be used as a supplement to the first embodiment above, wherein the raw water pipeline 201 communicates with the above-mentioned water supply pipeline and is used as a raw water source therein.

[0055] In this embodiment, the raw water pipeline 201 is connected to the water inlet of the pure water machine, and the raw water treatment pipeline is connected to the water inlet and the water outlet of the pure water machine. Preferably, the raw water pipeline 201 is arranged with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com