Parallel water supply cooling system for thermal stamping mold

A hot stamping die and cooling system technology, applied in the field of hot stamping, can solve the problems affecting the service life of products, uneven mechanical properties, long medium flow routes, etc., to achieve long life extension, uniform mechanical properties, and smooth flow of circulating water Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

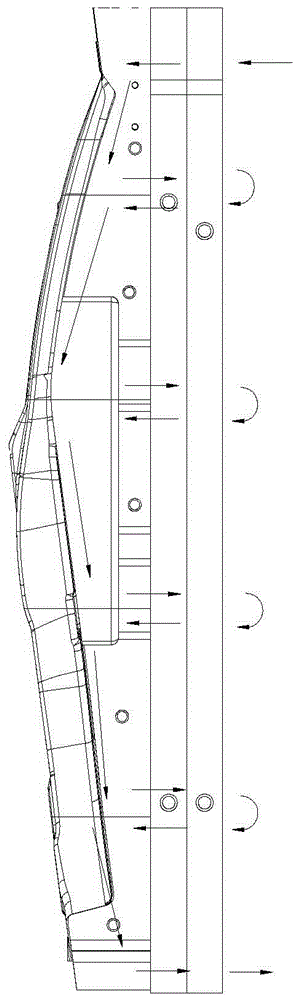

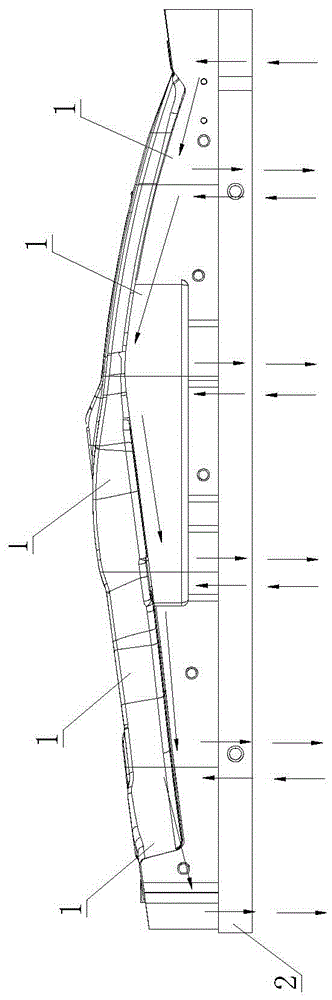

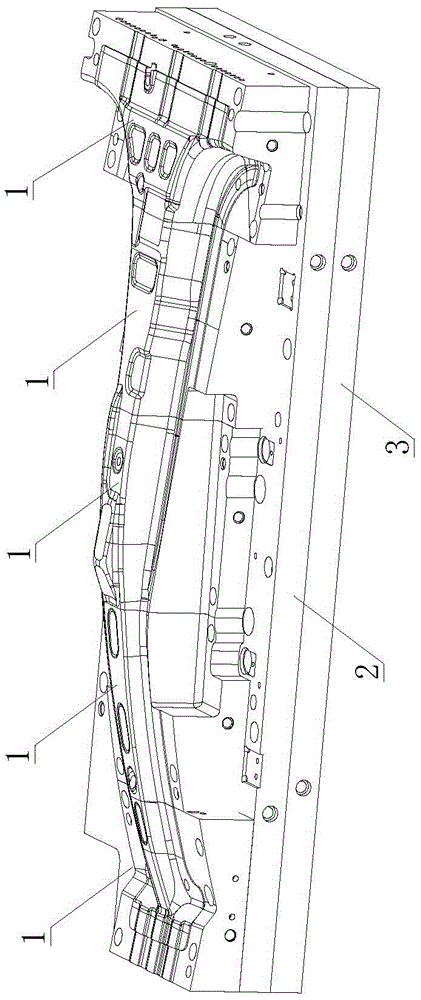

[0025] Such as Figure 2 to Figure 6 As shown, a parallel water supply and cooling system for hot stamping dies includes at least two forming males 1 and water dividing plates 2, each forming male 1 is provided with a cooling water channel 11, and the water dividing plates 2 are used for each Forming male 1 carries out independent water inlet and independent water collection, so that at least two forming male 1s form a parallel cooling circulation water circuit, and the water circulation of each forming male 1 is as follows: figure 2 In the direction indicated by the arrow.

[0026] In practical application, due to the limitation of product structure and mold processing, multiple forming t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com