Method for controlling an ultrasound motor and corresponding control arrangement

A control mechanism, ultrasonic technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, fluid using vibration, etc. Problems such as the complexity of motor manufacturing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

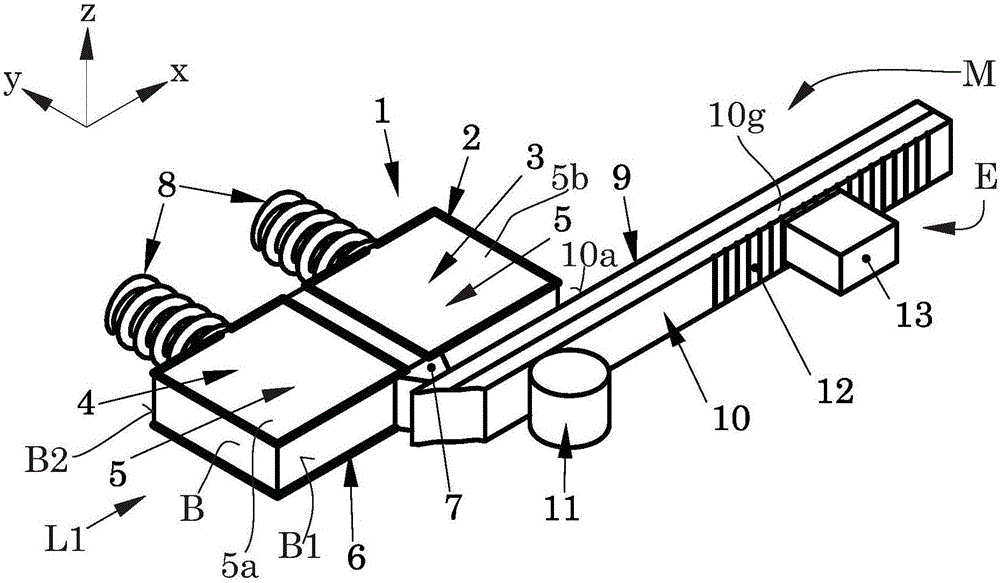

[0034] figure 1 A possible embodiment of an ultrasonic motor for applying the method according to the invention is shown. Ultrasonic motor M usually has:

[0035] - Ultrasonic actuator 1 having:

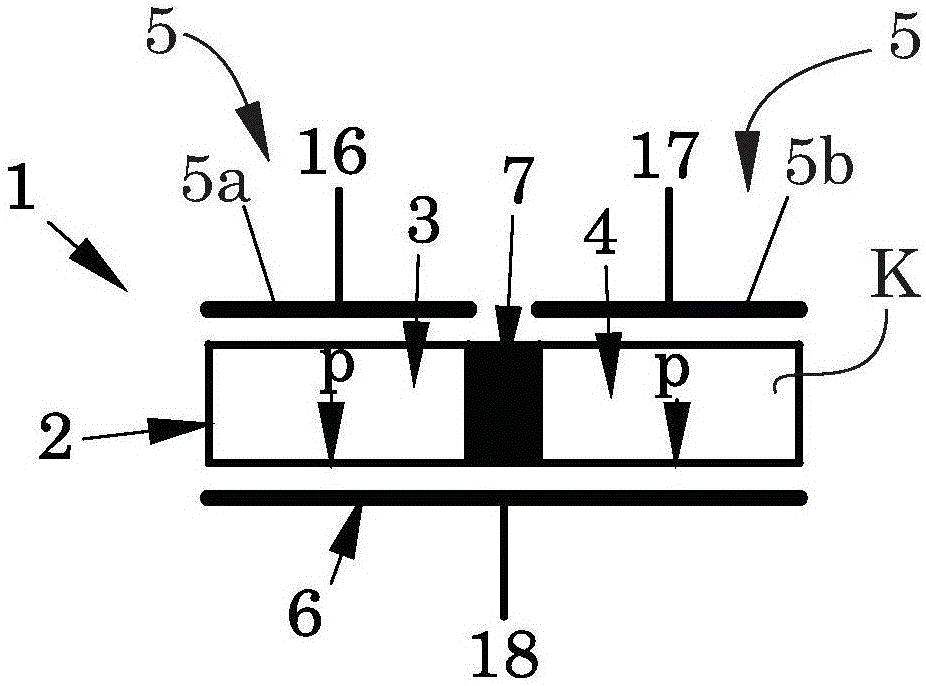

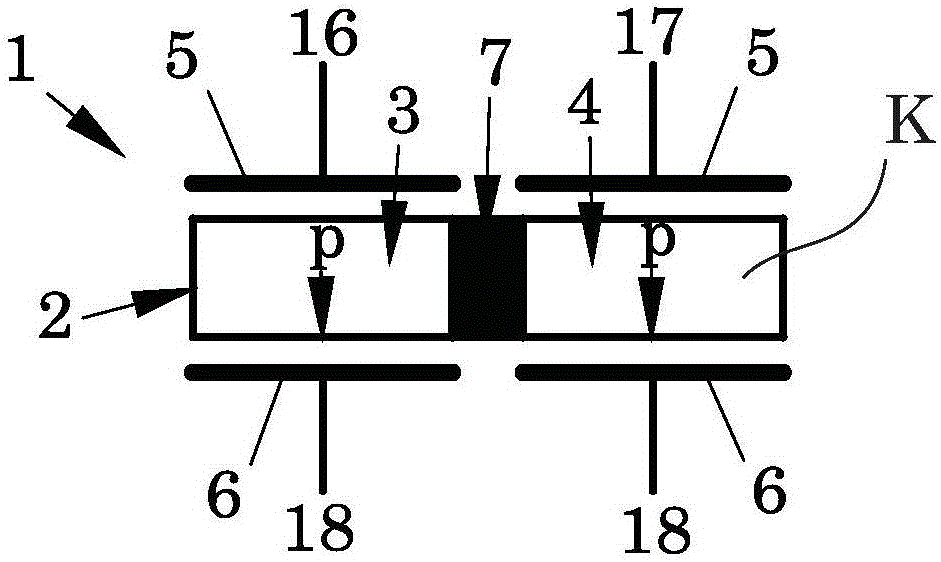

[0036] - at least one group of two generators 3, 4 each for generating sound waves, in particular ultrasonic waves, with a control device electrically connected to the generators 3, 4 for switching the first voltage U1 and / or the second A voltage U2 is applied to each of the generators 3, 4, said first voltage U1 being defined by a respective frequency and a respective amplitude, said second voltage U2 being defined by a respective frequency and a respective amplitude;

[0037]- a friction element 7 arranged between the generators 3, 4 of each group of generators 3, 4 and coupled with each of the generators 3, 4 of such a group, so as to be based on using the control of the first voltage U1 and / or the second voltage U2 to control the movement of the friction element 7 by mechanica...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap