Steel core cable

A technology of steel core and rope, which is applied in the direction of textile cables, textiles and papermaking, agricultural machinery and tools, etc., and can solve problems such as wire explosion, worker injury, and inconvenient on-site operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

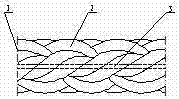

[0008] as attached figure 1 , 2 As shown, polypropylene fiber is used as the material for making the fiber strand layer 1 of the present invention, and the steel wire rope is the steel core. It is made of many polypropylene filaments twisted into chemical fiber bundles, and then braided with steel wire ropes into fiber ropes with steel cores through a specific process. Twisted into chemical fiber tows to form a fiber strand layer 1 on the outer layer of the steel core, and the steel wire rope is the steel core 2. Appropriate parts of the fiber rope with steel core made by the above process are connected with fasteners to realize synchronous operation with other machines. The soft surface of the fiber strand layer 1 placed on the outer layer during the operation meets the operator's hand feeling requirements, and the steel core 2 not only meets the bottom sinking requirements of marine operations, but also increases the strength of the rope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com