Cantilever structure for steel structure workshop

A technology for steel structures and workshops, which is applied in building construction and construction, and can solve problems such as inconvenient disassembly and installation, heavy upper structure weight, and complicated installation process, and achieve stable installation, improved construction efficiency, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

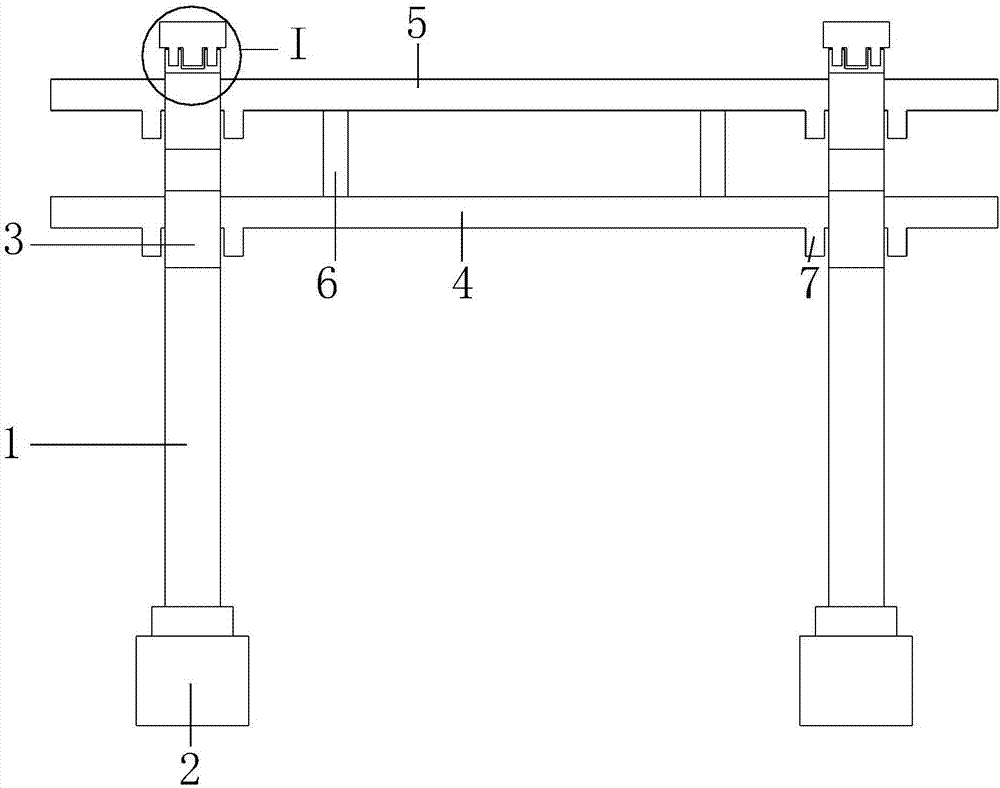

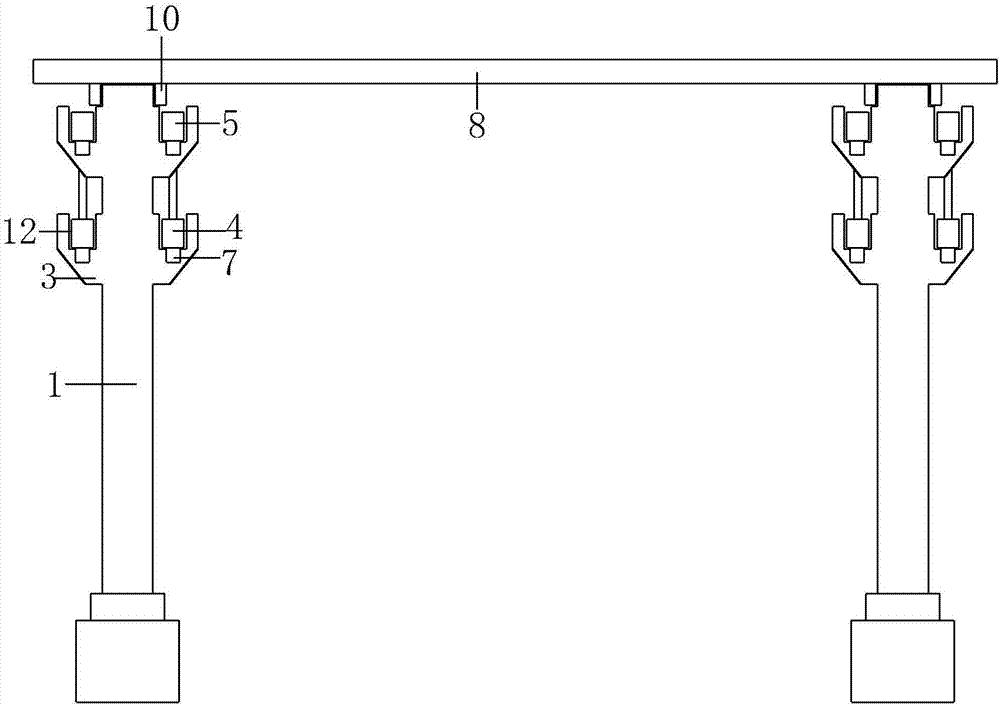

[0022] Such as Figure 1-Figure 3 As shown, a cantilever structure for a steel structure factory building according to the present invention includes a base 2, a column 1, a first cantilever beam 4, a second cantilever beam 5 and a top cantilever beam 8; The four corners are arranged and fixed on the corresponding base 2. Two layers of corbel support structures are arranged on the upper part of the column 1. Each layer of corbel support structure includes corbels 3 symmetrically arranged on both sides of the column 1, and the corbels 3 Grooves 12 are respectively set on the top; the two columns 1 in the same row are respectively connected by the first cantilever beam 4 and the second cantilever beam 5, wherein the two ends of the first cantilever beam 4 are respectively supported by the columns on both sides. 1 In the groove 12 of the lower corbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com