Flexible fastening bolt for elastic coupling

An elastic coupling and fastening bolt technology, applied in the direction of threaded fasteners, screws, connecting components, etc., can solve the problems of low strength, easy breaking of fastening bolts, and inability to meet the requirements of improving the carrying capacity of locomotives. Not easy to break effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

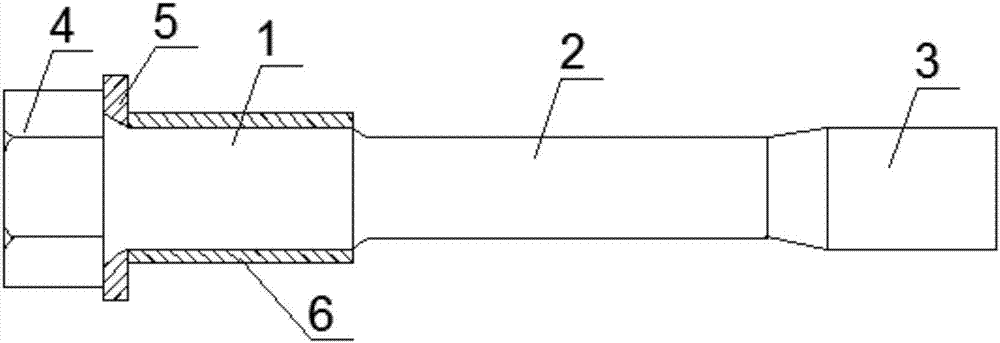

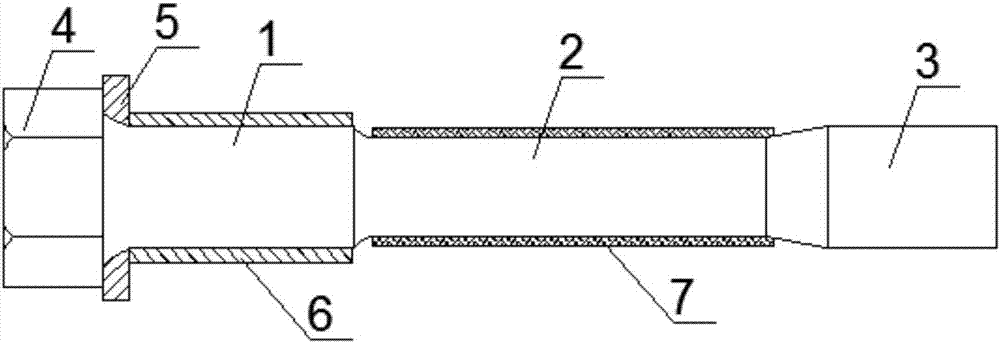

[0016] Such as figure 1 As shown, the flexible fastening bolt of the elastic coupling of the present invention includes a cylindrical part 1, a flexible hinge part 2, a threaded connection part 3, a bolt head 4, an elastic washer 5, and an elastic sleeve 6, wherein the flexible hinge part 2 Set between the cylindrical part 1 and the threaded connection part 3, the diameter of the cylindrical part 1 is the same as that of the threaded connection part 3 and larger than the diameter of the flexible hinge part 2, that is, the diameter of the cylindrical part 1 is larger than that of the flexible hinge part 2 diameter, the cylinder part 1 and the flexible hinge part 2 are polished rod cylinders.

[0017] The cylinder part 1 of the present invention, the flexible hinge part 2, the threaded connection part 3, and the bolt head 4 need a material with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com