Self-adaptive breather for tank

A respirator and self-adaptive technology, applied in the field of tank breathing, can solve the problems of safety accidents and low reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

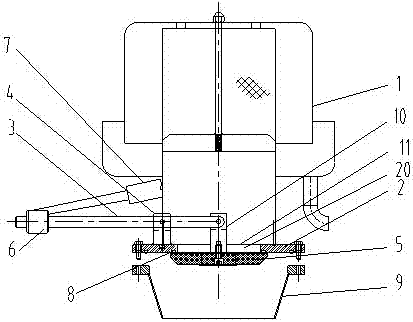

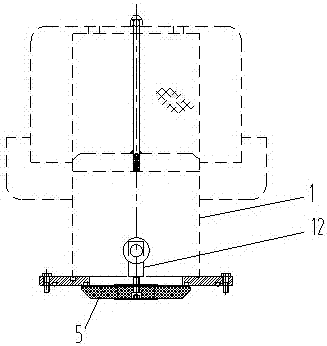

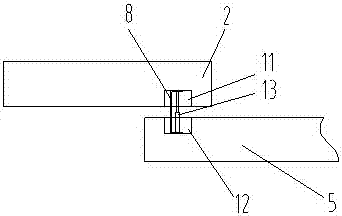

[0018] The present invention as Figure 1-3 As shown, the respirator is arranged on the tank body, the bottom of the respirator is connected with a flange 2, the bottom of the respirator has a middle hole 11, and the flange has a middle hole 20, The centerlines of the first middle hole and the second middle hole are consistent, and the diameter of the first middle hole is larger than that of the second middle hole; in application, the flange 2 is connected to the tank body 9 to work.

[0019] It also includes a lever 3, a lever seat 4, a gate 5, a counterweight 6, a pressure sensor and an electric push rod 7, the bottom side of the respirator is provided with an installation port 12, and the lever seat 4 is connected to the flange 2 and located in the installation port 12, the lever 3 is hinged on the lever seat 4, the gate 5 and the counterweight 6 are respectively connected to the two ends of the lever, the gate 5 is located under the flange 2, And it is used to close the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com