Stale waste incineration and building materials system

A waste incineration and stale technology, applied in incinerators, combustion types, clay products, etc., to achieve the effect of saving borrowed land and fuel, good environmental and social benefits, and conducive to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

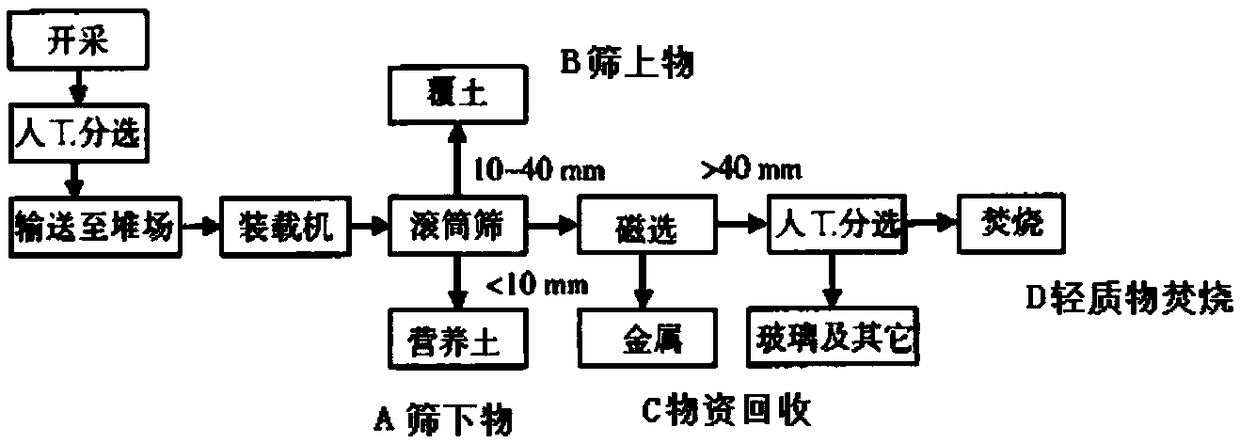

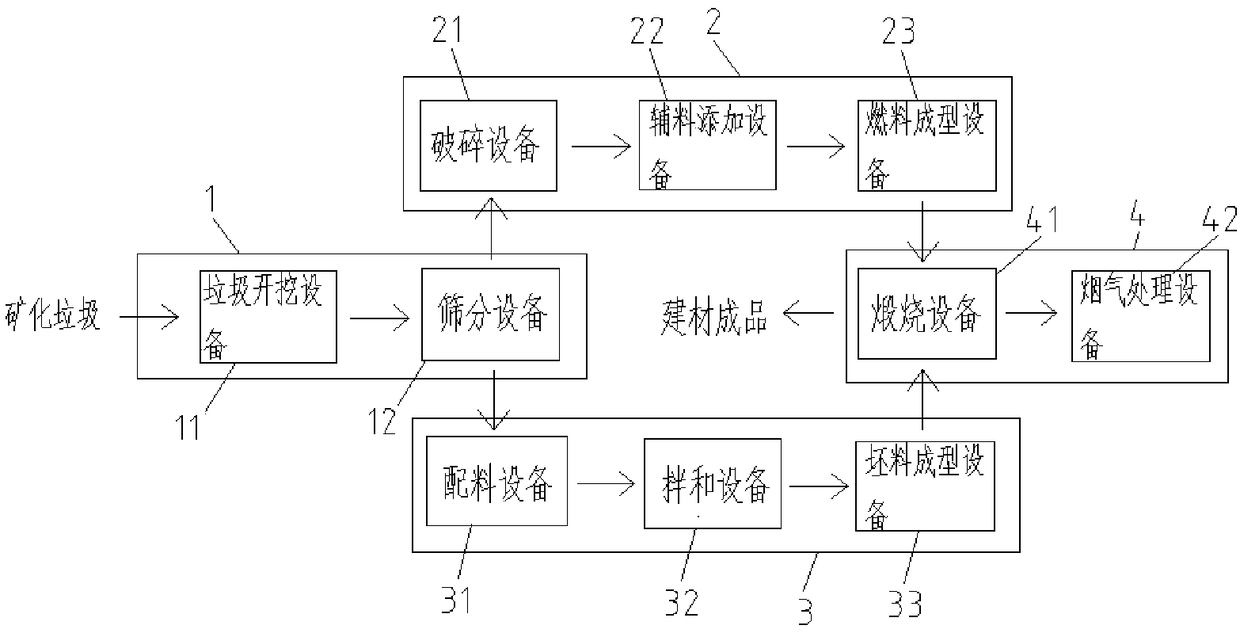

[0054] figure 2 The structure schematic diagram of the obsolete waste incineration and building materials system provided for the embodiment of the present invention; figure 2 As shown, the obsolete waste incineration and building materials system provided by the embodiment of the present invention includes an excavator screening device 1, an RDF preparation device 2, a humus soil blank making device 3 and a calcined finished product device 4;

[0055] The excavator screening equipment 1 is used to divide stale garbage into oversize and undersize, a part of the oversize is light substances with a certain calorific value, and the undersize is humus;

[0056] The RDF preparation device 2 is used to make RDF from combustibles on the sieve;

[0057] The humus soil billet making device 3 is used to make the undersize material into a billet;

[0058] The finished product calcination device 4 uses the RDF as fuel to calcine the billet to produce a finished building material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com