A method for determining the target line size for solid propellant burning rate test

A technology of solid propellants and determination methods, which is applied in special data processing applications, chemical analysis by combustion, design optimization/simulation, etc., and can solve problems such as low strength of the target line, easy breakage of the target line, and large size of the target line. Achieve the effect of strong adaptability to conditions, simple determination process and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

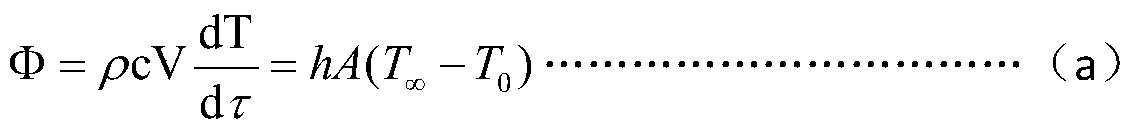

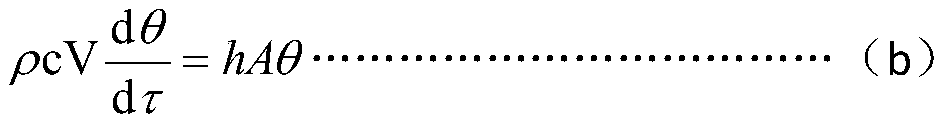

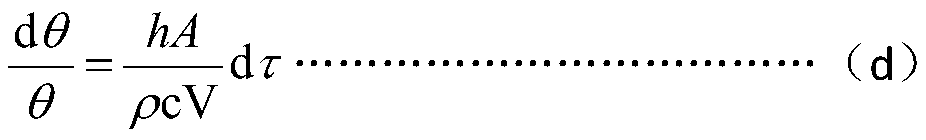

Method used

Image

Examples

Embodiment 1

[0031] The propellant to be tested for the burning rate is a double-base propellant. The propellant is cut into a cylindrical drug rod with a size of Φ5×60mm, and the combustion wave curve of the drug rod is tested at 3MPa. Surface temperature t ∞ =600K. The target line used in the burning rate test is lead-antimony alloy wire with a melting point of 519K, and the length of the target line embedded in the propellant bar can be known from the size of the propellant bar to be 5mm. The burning rate test requires the maximum fusing time [τ] of the target line to be 1.7ms, and the optimum target line diameter for the propellant in the 3MPa burning rate test calculated by the mathematical model is 1.1mm.

Embodiment 2

[0033] The propellant to be tested for the burning rate is a double-base propellant. The propellant is cut into a cylindrical drug rod with a size of Φ5×60mm, and the combustion wave curve of the drug rod is tested at 10MPa. Surface temperature t ∞ =600K. The target line used in the burning rate test is lead-antimony alloy wire with a melting point of 500K, and the length of the target line embedded in the propellant bar is 5 mm from the size of the propellant bar. The burning rate test requires the maximum fusing time [τ] of the target line to be 4.1ms, and the optimum target line diameter for the propellant in the 10MPa burning rate test calculated by the mathematical model is 2.3mm.

Embodiment 3

[0035] The propellant to be tested for the burning rate is a fuel-rich propellant. Cut the propellant into cuboid sticks with a size of 4×4×60mm, and test the combustion wave curve of the stick at 8MPa. The propellant obtained through the combustion wave test experiment Burning surface temperature t ∞ =700K. The target line used in the burning rate test is a lead-antimony alloy wire with a melting point of 500K, and the length of the target line embedded in the propellant bar is 4mm from the size of the propellant bar. The burning rate test requires the maximum fusing time [τ] of the target line to be 4.7ms, and the optimum target line diameter for the propellant's burning rate test at 8MPa calculated by the mathematical model is 3.3mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com