Electronic device and method for manufacturing same

A technology of electronic devices and light emitting devices, which is applied in the direction of electrical equipment casings/cabinets/drawers, electrical components, casings/cabinets/drawer components, etc., and can solve problems such as limiting design freedom and manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

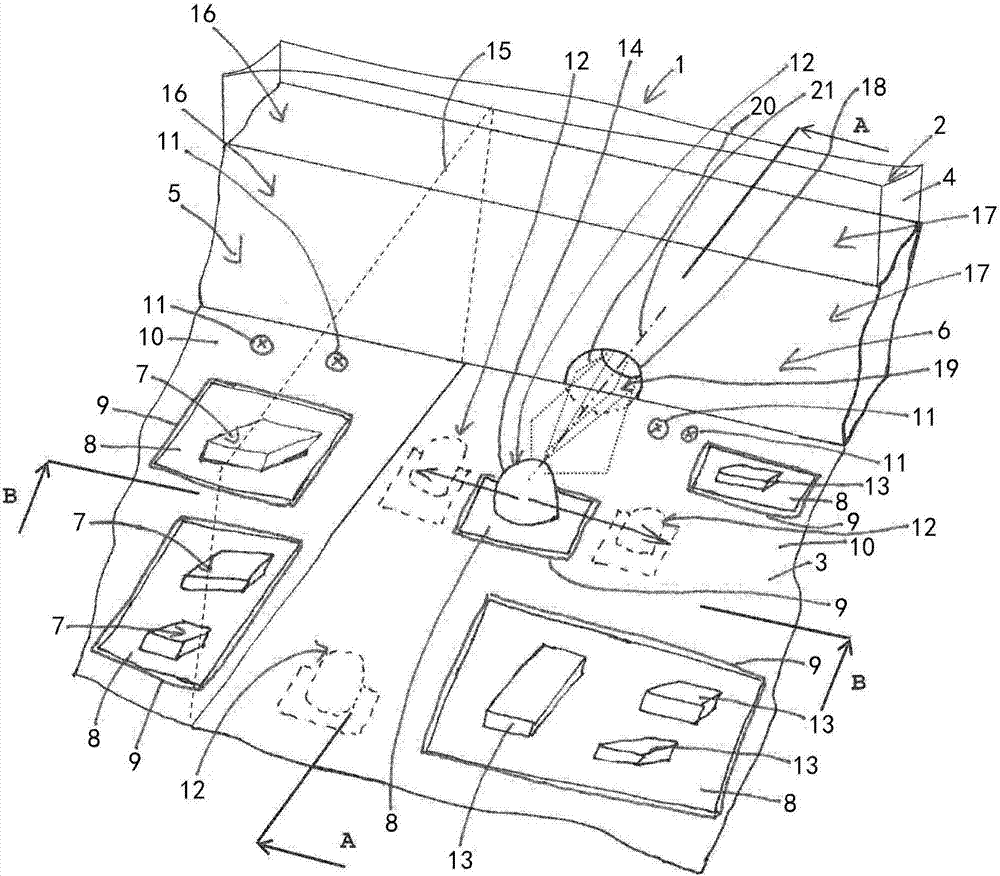

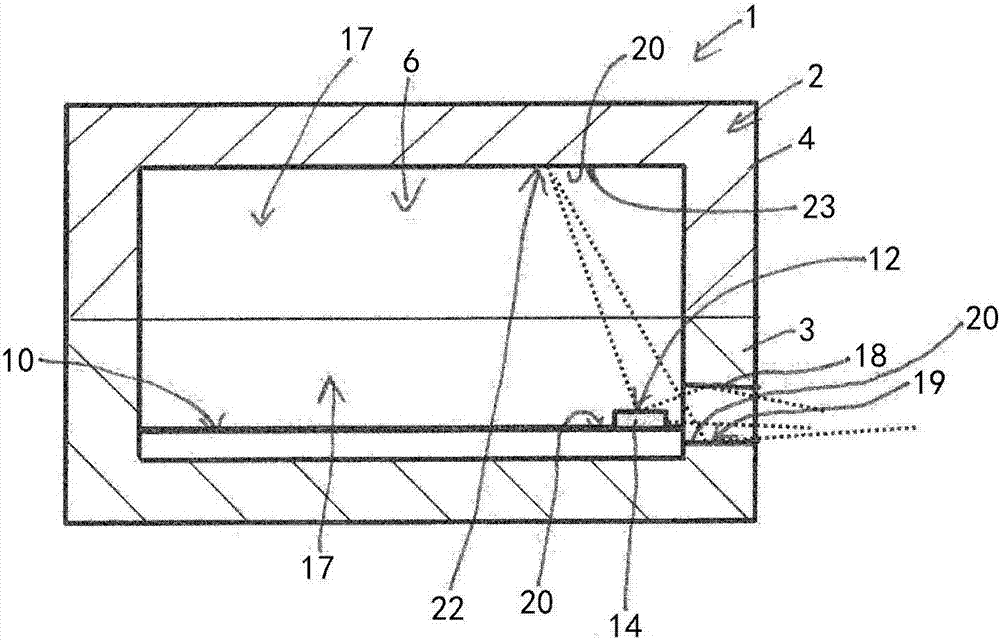

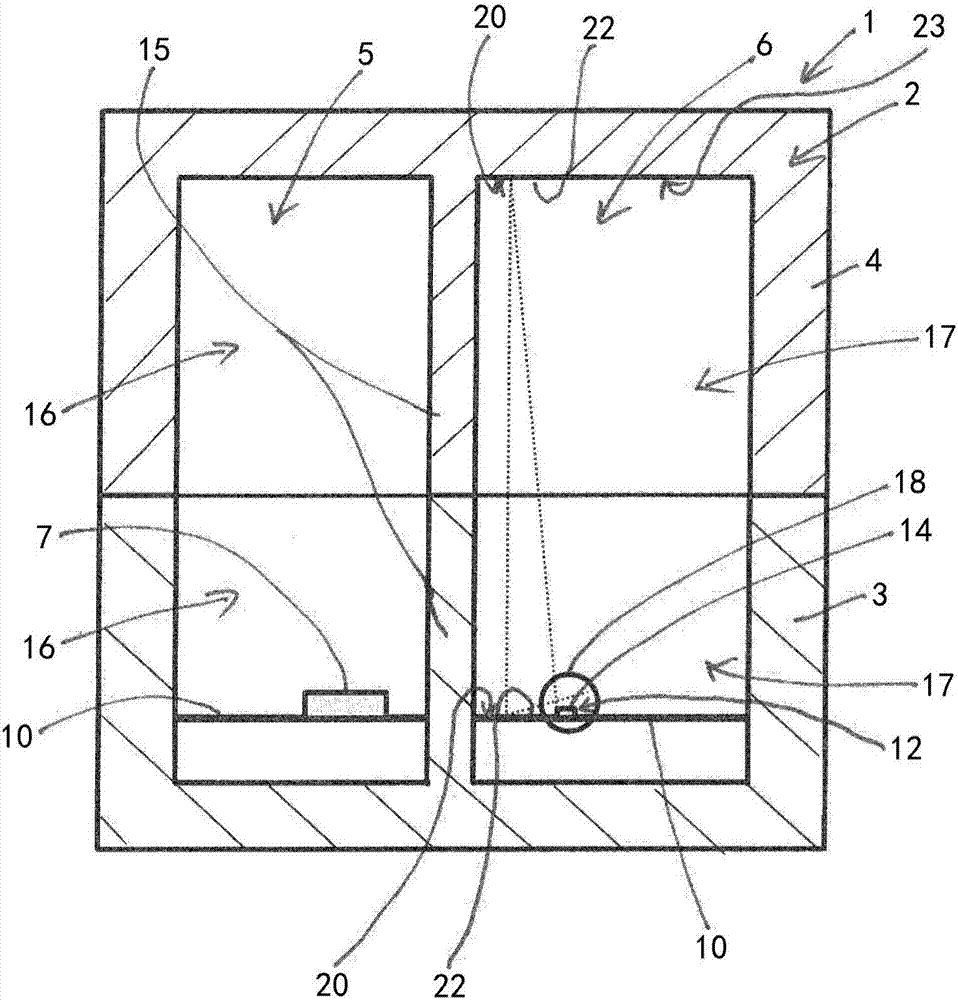

[0033] exist figure 1 , 2 and 3, an electronic device 1 according to an embodiment of the present invention is shown. figure 1 A schematic diagram of a part of the electronic device 1 is shown. further, figure 2 show the basis figure 1 The cross-section A-A of the electronic device, image 3 is based on figure 1 Cross-section B-B of the electronic device. It should be noted, figure 1 , 2 and 3 are only schematic and not to scale. Further, connections including electrical connections of the different components of the electronic device 1 , especially between these components, are not shown in the figures for the sake of clarity.

[0034] Such as figure 1 , 2 As shown in and 3 , the electronic device 1 includes a casing 2 , and the casing 2 includes a first half 3 and a second half 4 . The housing 2 is further subdivided into at least a first chamber 5 and a second chamber 6 .

[0035] In the first cavity 5 one or more electronic components 7 are housed. A plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com