Ceramic pot structure

A ceramic pot and pot body technology, applied in the field of ceramic products, can solve the problems of poor sealing at the joint between the pot body and the pot cover, large air flow, inconvenient operation, etc. The effect of boosting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

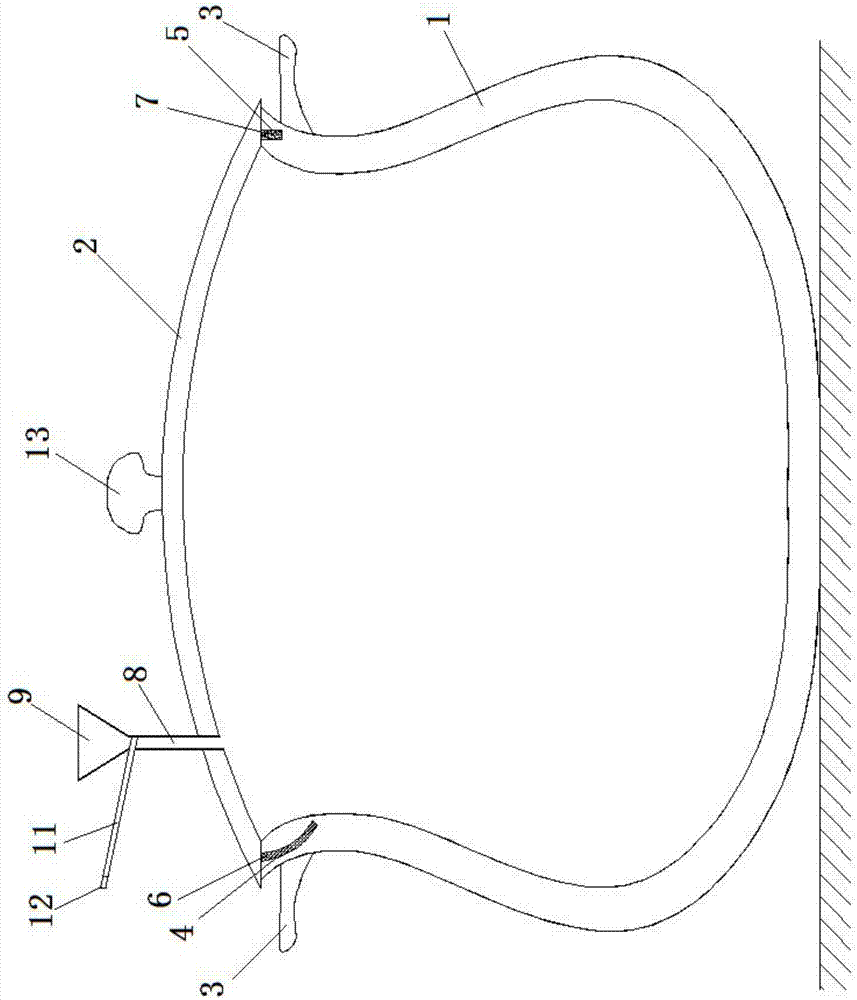

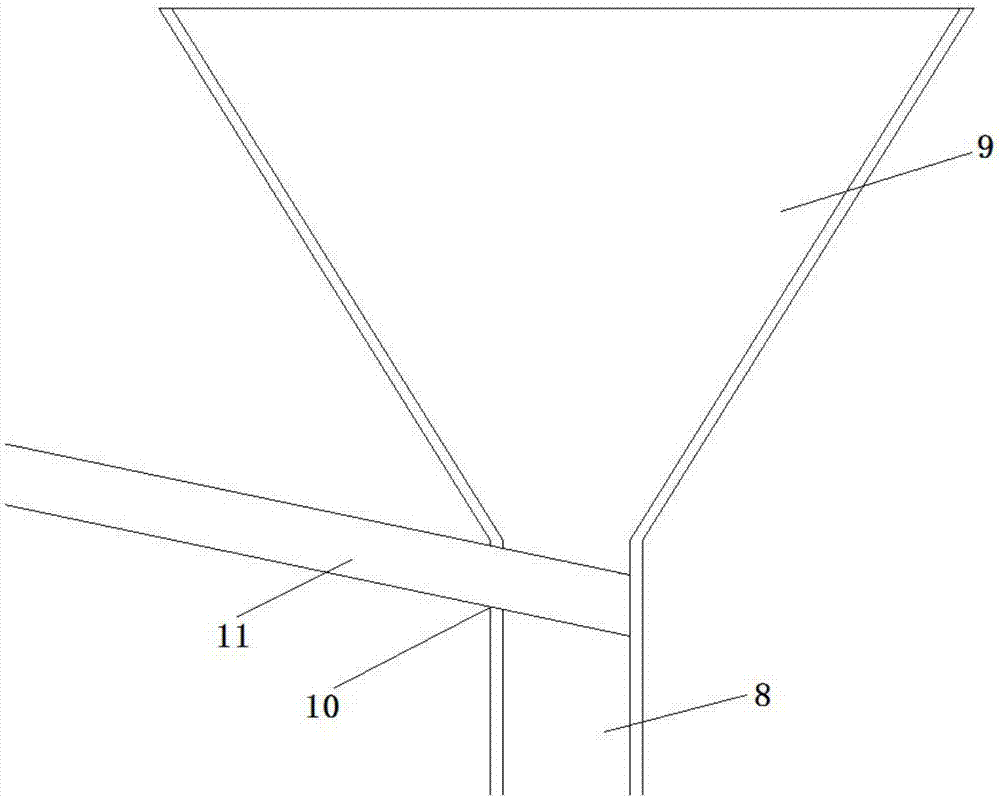

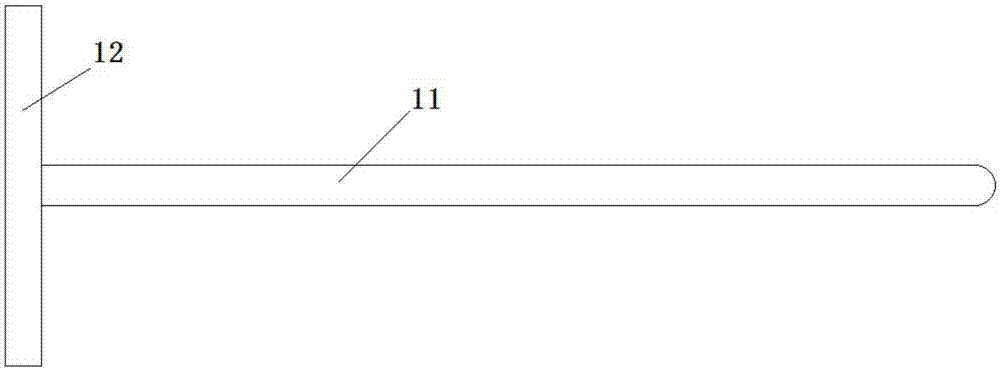

[0033] Such as Figure 1-5 As shown, a ceramic pot structure includes a pot body 1 and a pot cover 2, two symmetrical pot ears 3 are arranged on the outer wall of the pot body 1, and a section is arranged on the left side of the pot body 1. The arc slot 4, the remaining pot edge of the pot body 1 is provided with a vertical slot 5, and the bottom edge of the pot cover 2 is provided with a position corresponding to the arc slot 4, the vertical slot 5 and the size Matching arc plate 6 and vertical plate 7, the left side of the pot cover 2 is provided with a feed pipe 8, the top of the feed pipe 8 is connected to the seasoning hopper 9, and the bottom of the feed pipe 8 runs through the pot cover 2. There is a through baffle slot 10 on the left side wall of the feeding pipe 8, and a baffle 11 is inserted obliquely downward in the baffle slot 10, and the rightmost end of the baffle 11 is against the On the inner wall of the feeding pipe 8 , the left end of the baffle 11 is provid...

Embodiment 2

[0038] A ceramic pot structure, including a pot body 1 and a pot cover 2, two symmetrical pot ears 3 are arranged on the outer wall of the pot body 1, and an arc-shaped insert is arranged on the left side of the pot body 1. Slot 4, the remaining pot edge of the pot body 1 is provided with a vertical slot 5, and the bottom edge of the pot cover 2 is provided with a slot corresponding to the position of the arc slot 4 and the vertical slot 5 and matching in size. Arc plate 6 and vertical plate 7, the left side of described pot cover 2 is provided with a feeding pipe 8, and the top of described feeding pipe 8 is connected with seasoning hopper 9, and the bottom of described feeding pipe 8 runs through pot cover 2, so The left side wall of the feeding pipe 8 is provided with a through baffle slot 10, and a baffle 11 is inserted obliquely downward at the baffle slot 10, and the rightmost end of the baffle 11 is against the feeding pipe 8. On the inner wall of the baffle plate 11, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com