Dust collector

A technology for vacuum cleaners and dust cups, which is applied in the direction of vacuum cleaners, electrical components, cleaning equipment, etc. It can solve the problems of potential safety hazards in vacuum cleaners and easy prolapse of power cords, and achieve the effect of preventing power cords from protruding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

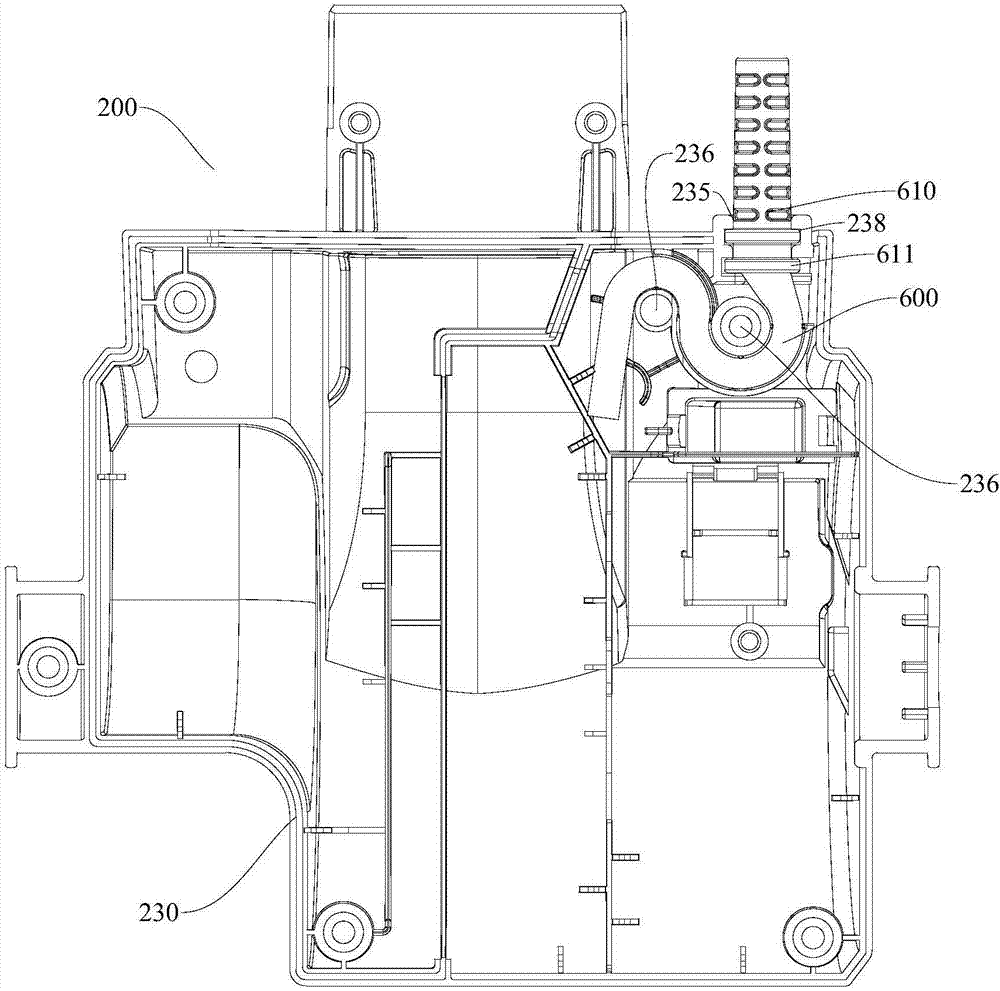

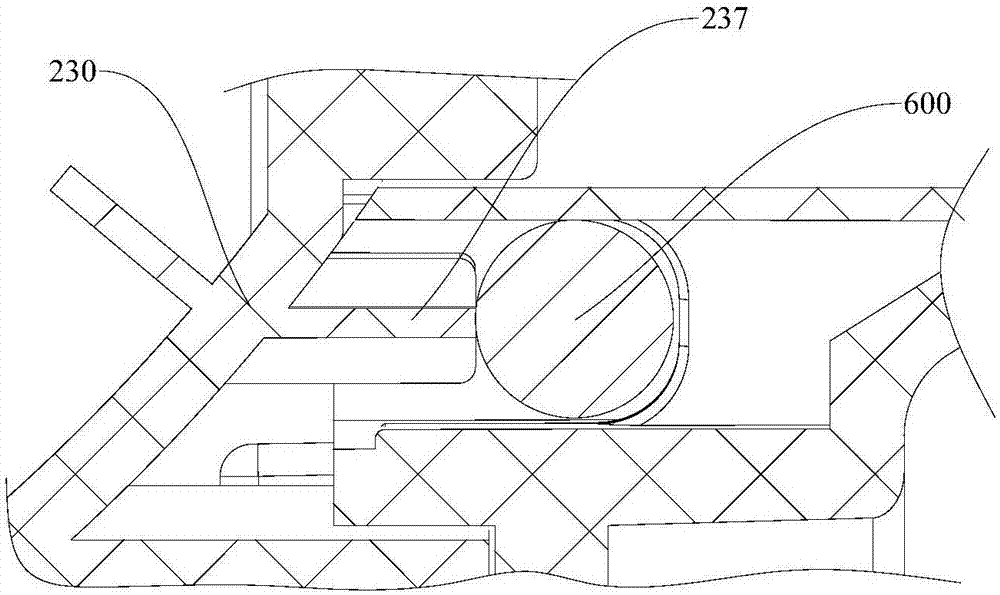

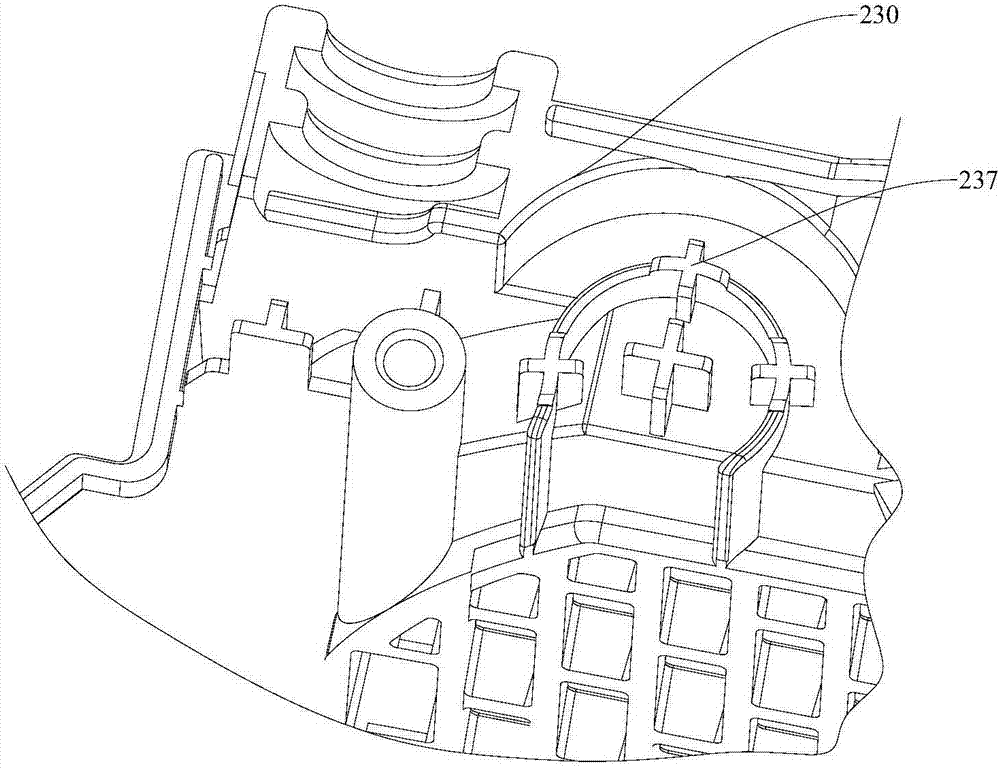

[0036] Refer below Figure 1-Figure 9 A specific structure of the vacuum cleaner 1000 according to the embodiment of the present invention will be described.

[0037] Such as figure 1 , Figure 7 As shown, a vacuum cleaner 1000 according to an embodiment of the present invention has a ground brush assembly 100 , a motor assembly 200 , a body assembly 300 , a dust cup assembly 400 and a power cord 600 .

[0038] The motor assembly 200 is connected to the ground brush assembly 100, the fuselage assembly 300 is connected to the rear end ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap