Streamline labeling machine

A labeling machine and streamline technology, applied in labeling machines, labels, packaging, etc., can solve problems such as complicated debugging, difficult implementation, general labeling effect, etc., to achieve easy on-site layout and matching, simple overall structure, and smooth operation The effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

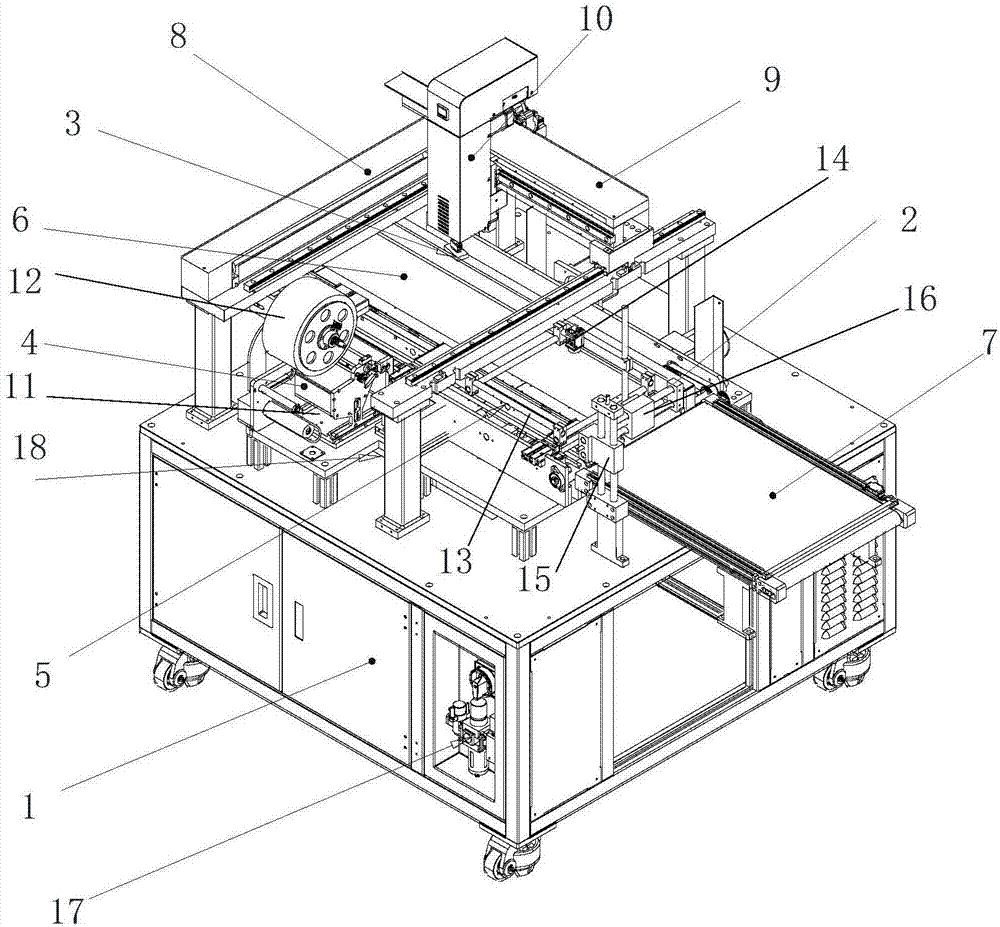

[0033] like figure 1 The streamlined labeling machine includes the lower frame 1, which is different in that: in order to meet the streamlined operation, the material conveying equipment is installed on the lower frame 1, and the discharge end of the material conveying equipment is set There is a visual inspection component 2, which can detect the excellent condition of the labeling at the first time. Considering the different labeling positions, accurate labeling can be carried out for different products. A motion guiding device is set up on the material conveying equipment, and a suction label device 3 is installed on the motion guiding device. In this way, the label w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com