An astrolabe rotary labeling machine

A technology of labeling machine and astrolabe, applied in the field of astrolabe rotary labeling machine, can solve the problems of reducing production efficiency, limited label length, loss, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

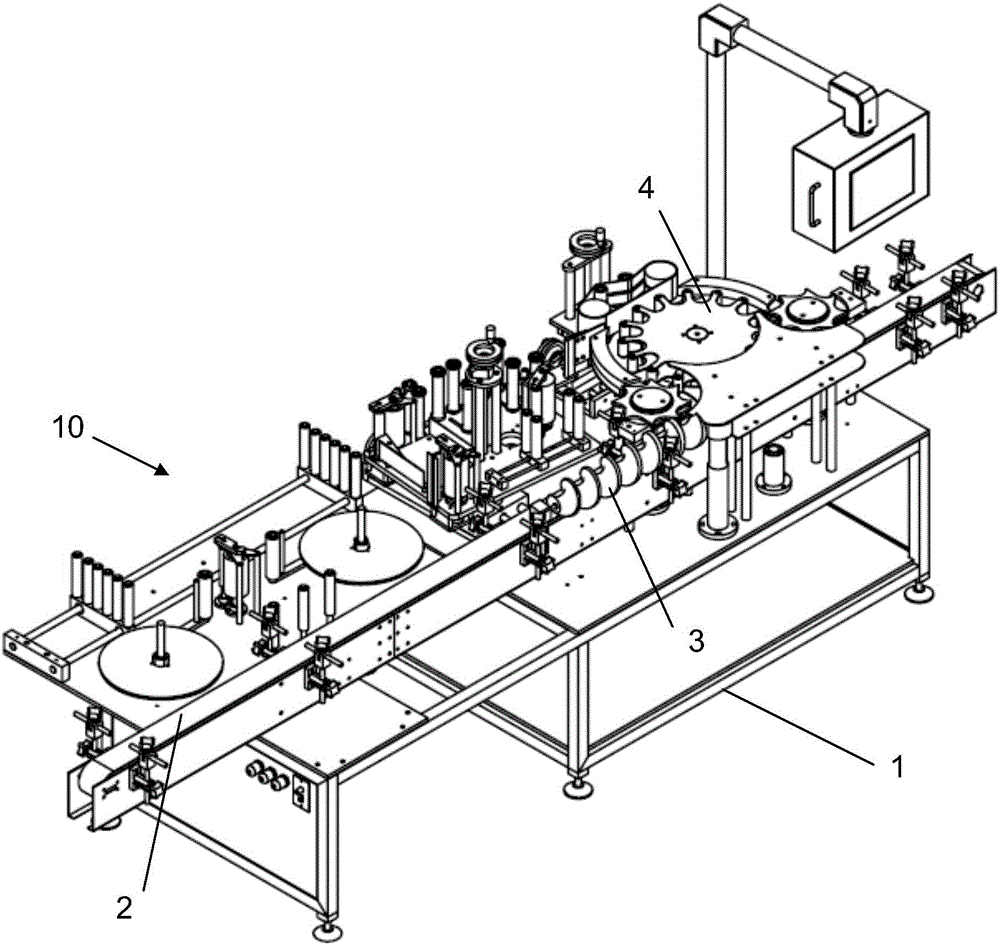

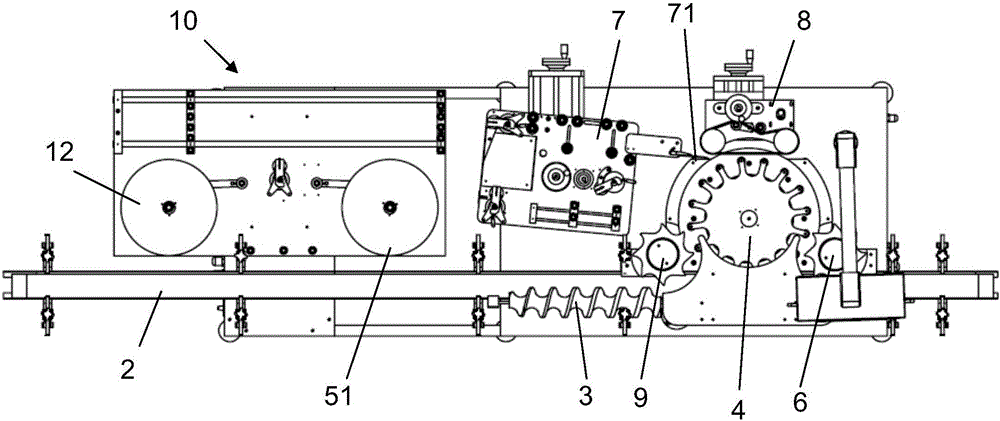

[0043] An astrolabe rotary labeling machine of the present invention such as Figure 1-2 As shown, it mainly includes a frame 1, two conveying lines arranged on the frame 1, one is a bottle conveying line composed of a bottle conveying belt 2, a bottle separating screw 3, and a bottle supporting turntable 4 arranged in sequence, and the other One road is a label conveying line composed of an online label changing mechanism 10 , a labeling mechanism 7 and a label handling mechanism 8 arranged in sequence. Among them, both sides of the bottle supporting carousel 4 are also provided with an in-bottle astrolabe 9 and a bottle-out astrolabe 6; The bottle-separating screw 3, and after the bottles are divided by the bottle-separating screw 3, enter the bottle-carrying turntable 4 one by one through the bottle-infeed star plate 9, and rotate with the bottle-carrying turntable 4 to the dial plate 71, and the label is changed by the online label changing mechanism 10 is output to the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com