A lifting mechanism, hot melt adhesive label station trolley and combined labeling machine

A technology of lifting mechanism and glue label station, which is applied in the field of lifting mechanism and combined labeling machine, and can solve the problems of low practicability, complicated operation and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

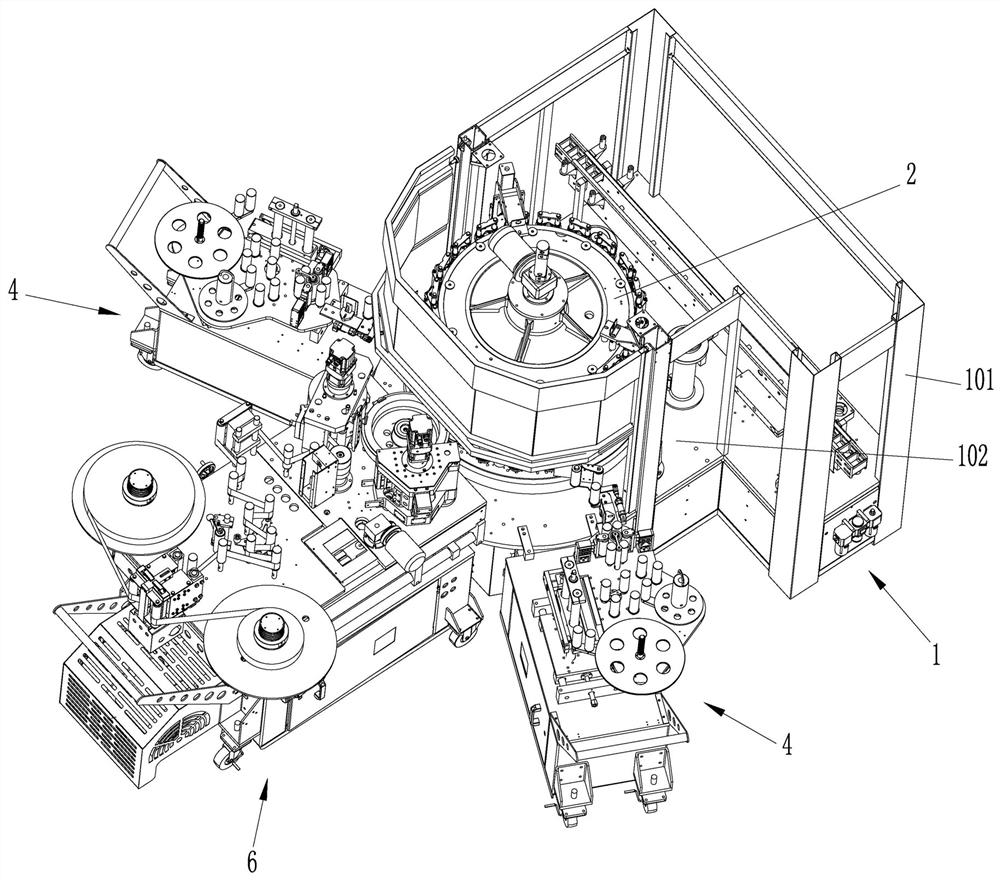

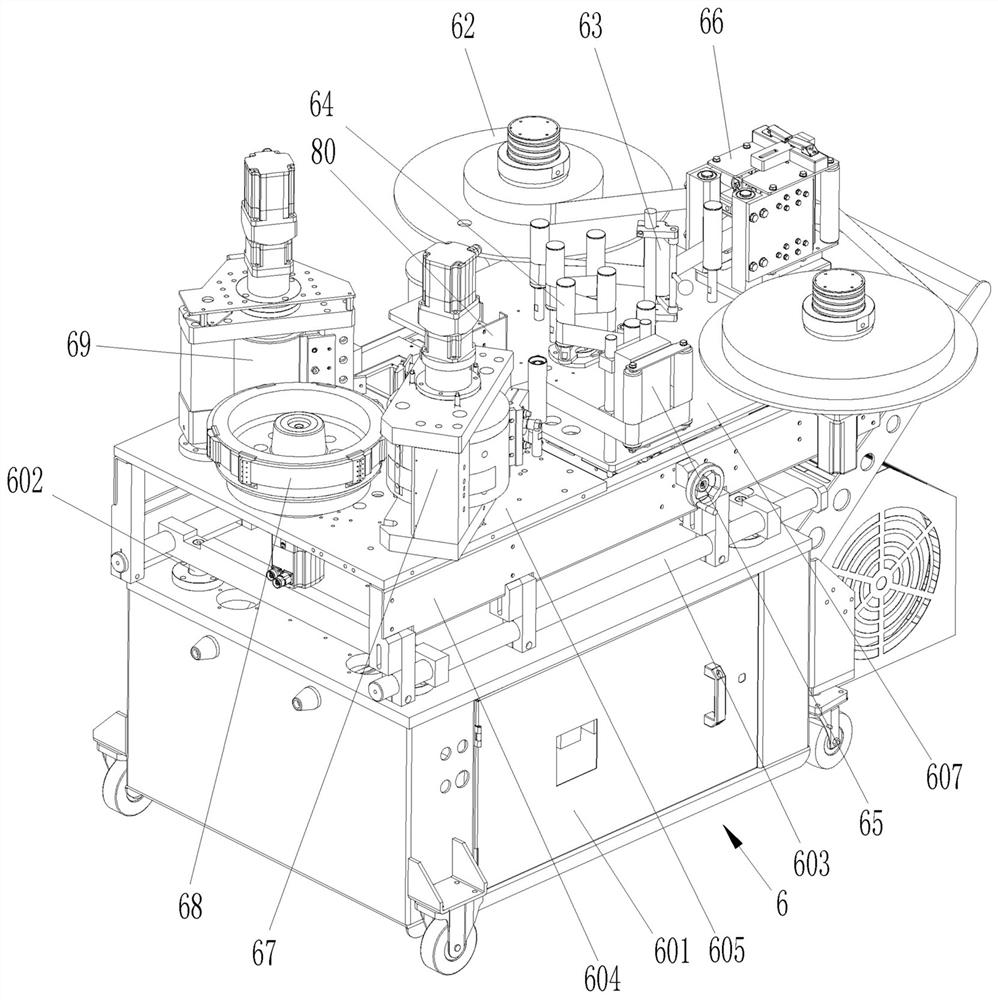

[0031] Such as figure 1 As shown, a combined labeling machine includes a frame 1, a bottle holder device 2, a hot melt adhesive label station trolley 6 and two self-adhesive label station trolleys 4;

[0032] The frame 1 includes an outer frame 101 and a table panel 102, the bottle holder device 2 is arranged on the table panel 102, the hot-melt adhesive label station trolley 6 is arranged at the front end of the frame 1, and the two self-adhesive label station trolleys 4 are arranged on the hot-melt label station. Both sides of the glue label station trolley 6; between the hot melt glue label station trolley 6 and the frame 1 and between the self-adhesive label station and the frame 1 are provided with connecting devices 5 .

[0033] Such as Figure 4 As shown, the connection device 5 includes a concave platform fixing bracket 501, two conical concave platforms 502 fixed on the concave platform fixing bracket 501, two conical positioning bodies 503 matched with the two conic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com