Cotton net cleaner with equivalent air pressure

A cleaner and cotton net technology, applied in the field of cotton net cleaner, can solve problems such as uneven suction of carded fibers, poor effect of removing impurities and lint, and affecting the quality of carded sliver, so as to improve the effect of removing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

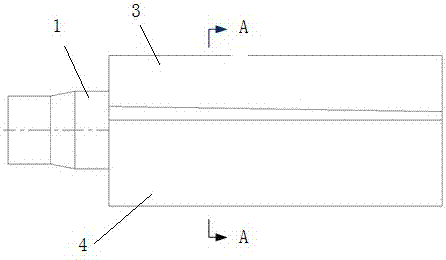

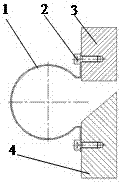

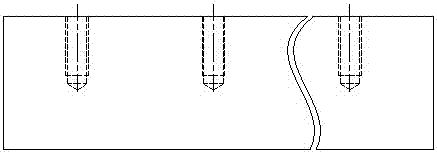

[0013] An isobaric cotton web cleaner such as Figure 1-Figure 4 As shown, it is characterized in that: the two sides of the dust collection cover 1 are respectively fixedly connected with the deflector 3 and the dust removal knife 4 with connecting screws 2, the inner side of the deflector 3 is a right-angled edge in the shape of a curve or an oblique line, and the dust removal knife 4. The inner cutting edge is a straight edge, and the two are installed correspondingly to form a dust suction port of unequal width. Even, it is beneficial for the suction port to evenly absorb short fibers and impurities from the surface of the cylinder, and improve the quality of the cotton web and the index of yarn formation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com