A quick reset device for a large piston of a high-pressure water pump

A reset device and a large piston technology are applied to piston pumps, parts of pumping devices for elastic fluids, pumps, etc., which can solve problems such as large water potential difference, environmental protection, and high power consumption, and achieve easier opening and improved Effects of resetting sensitivity and increasing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

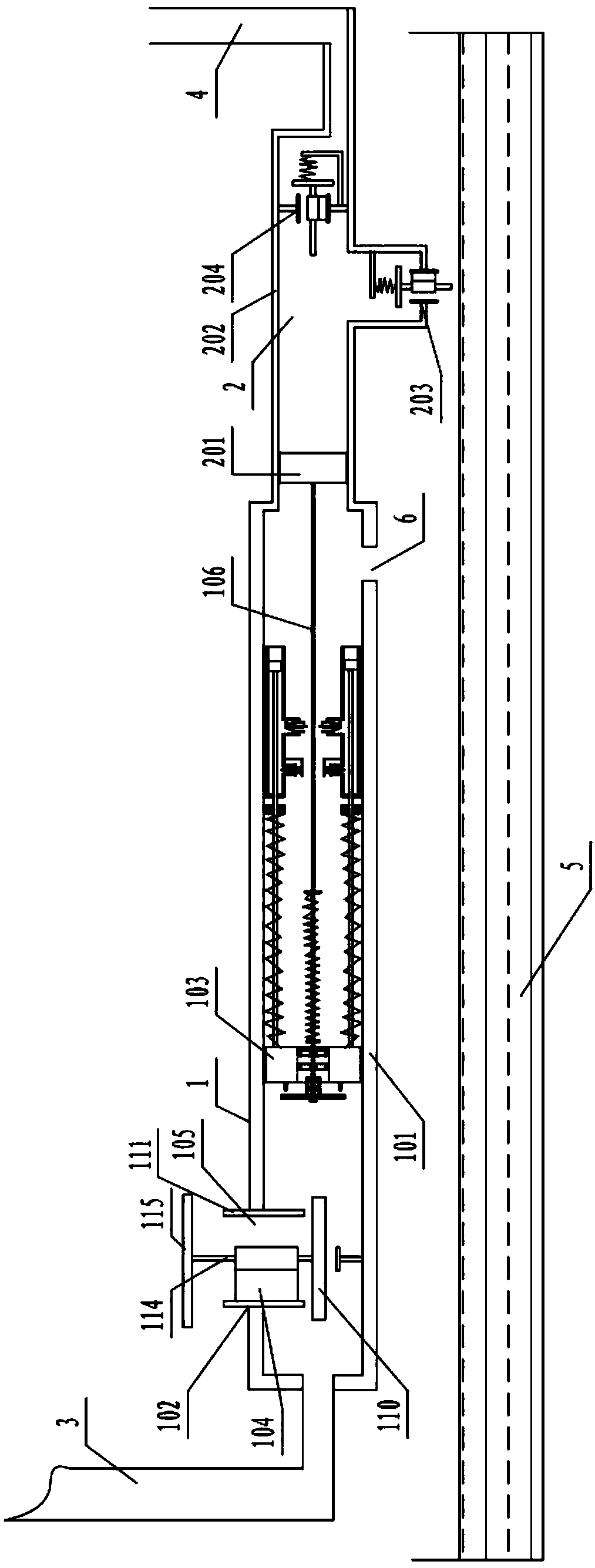

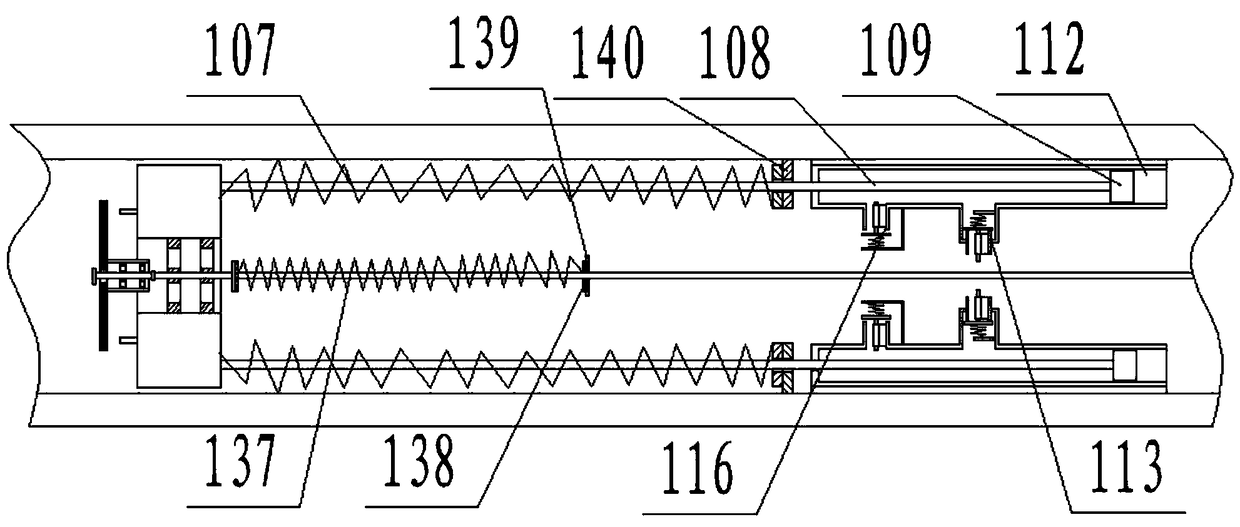

[0020] Embodiment 1: as Figure 1~Figure 6 As shown, a quick reset device for a large piston of a high-pressure water pump, the right side of the large piston 103 is provided with a return spring 107, one end of the return spring 107 is fixedly connected to the right end face of the large piston near the outer edge, and is sleeved on the support rod 108, and the other end Connected to the fixed seat plate 140 and can expand and contract along the support rod 108, the left end of the support rod 108 is fixedly connected to the large piston 103, and the right end is connected to the reset piston 109, and the reset piston 109 is placed in the reset piston chamber 112 opened at the right end, and the reset piston The cavity 112 is fixedly connected to the cavity body 101, the support rod 108 passes through the fixed seat plate 140 movably, and the reset spring and the reset piston connected to the support rod are arranged in two symmetrical pairs, which play the role of reset force...

Embodiment 2

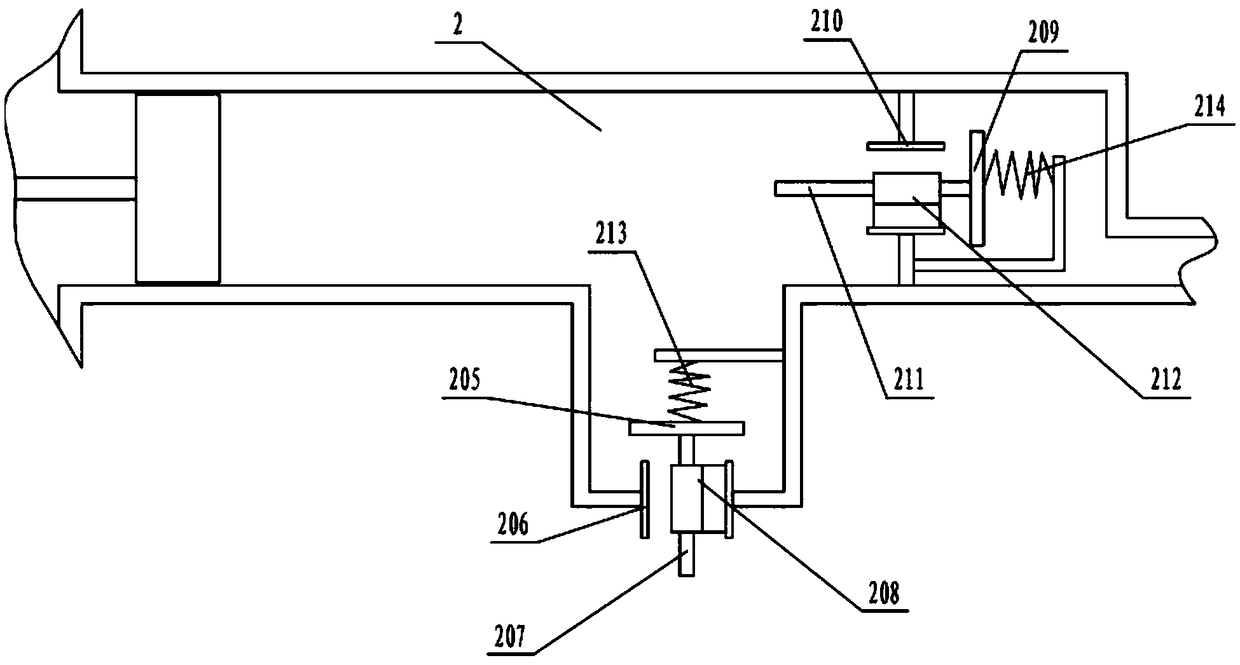

[0025] Embodiment 2: The large piston quick reset device of the above-mentioned high-pressure water pump is used in a high-pressure water pump, the high-pressure water pump includes a pressurizing device 1 and a water pump 2, and the water inlet pipe 3 of the pressurizing device 1 is connected to a high-level water source and can drive the water pump 2 to act. The water pump 2 is provided with a water inlet and a water outlet. The water inlet of the water pump 2 is connected to the reservoir 5 or the water source port at the position. The water in the reservoir is the water overflowed by the pressurization device. , the water outlet is connected to the user water supply pipe 4.

[0026] Preferably, the above-mentioned pressurizing device 1 includes a cavity 101, the side wall of the water inlet end of the cavity 101 is provided with a valve 102, and the water outlet end is provided with a piston pushing mechanism, the piston pushing mechanism includes a large piston 103 and a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com