LED (Light-emitting Diode) project lamp manufacturing method and LED (Light-emitting Diode) project lamp manufactured through method

A technology for LED floodlights and manufacturing methods, which is applied to semiconductor devices of light-emitting elements, light sources, electric light sources, etc., which can solve the problems that LED floodlights cannot accurately illuminate rectangular areas to be illuminated with fixed dimensions, and achieve improved lighting quality , saving power consumption, the effect of large demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The method for manufacturing an LED floodlight provided in Embodiment 1 of the present invention includes the following steps:

[0035] Determining the length, width and area of the rectangular surface to be irradiated, the focal length and diameter of the lens 4 to be used by the LED floodlight, the vertical distance between the LED floodlight and the surface to be illuminated, and the projection angle of the LED floodlight;

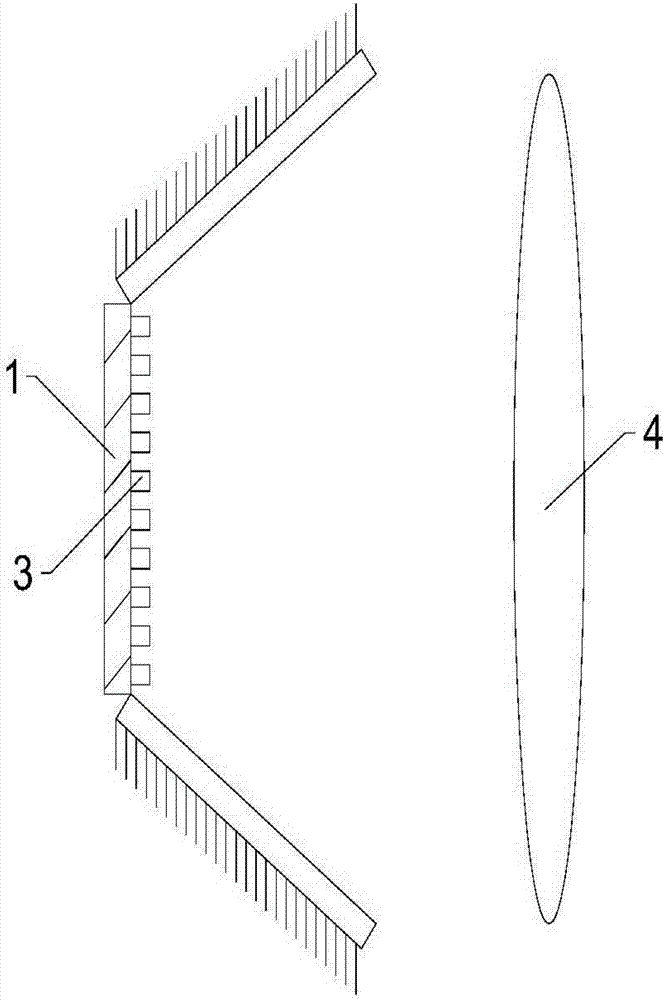

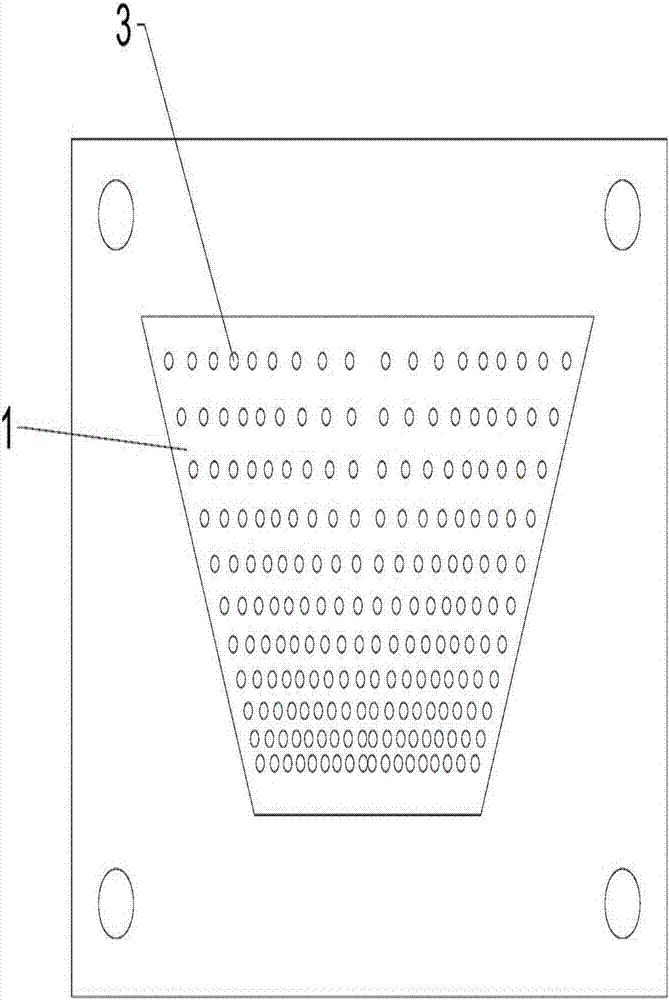

[0036] According to the size and area of the rectangular surface to be irradiated, the focal length and diameter of the lens 4 to be used by the LED floodlight, the vertical distance between the LED floodlight and the surface to be irradiated, and the imaging principle of the lens 4, the ideal illumination state is calculated ( That is, when the projection angle is 90°), the overall dimensions of the light board 1;

[0037] Make an experimental light source according to the focal length and diameter of the lens 4 used by the light board 1 and...

Embodiment 2

[0052] The method for manufacturing an LED floodlight provided by Embodiment 2 of the present invention includes the following steps:

[0053] Determining the length, width and area of the rectangular surface to be irradiated, the focal length and diameter of the lens 4 to be used by the LED floodlight, the vertical distance between the LED floodlight and the surface to be illuminated, and the projection angle of the LED floodlight;

[0054] According to the size and area of the rectangular surface to be irradiated, the focal length and diameter of the lens 4 to be used by the LED floodlight, the vertical distance between the LED floodlight and the surface to be irradiated, and the imaging principle of the lens 4, the ideal illumination state is calculated ( That is, when the projection angle is 90°), the overall dimensions of the light board 1;

[0055] Make an experimental light source according to the focal length and diameter of the lens 4 used by the light board 1 and...

Embodiment 3

[0083] Embodiment 3 is a method for making an LED floodlight with a rectangular projection area:

[0084] Now assume that the design of LED floodlights for lighting a single-column rectangular billboard with a specification of 6 meters x 18 meters is an example:

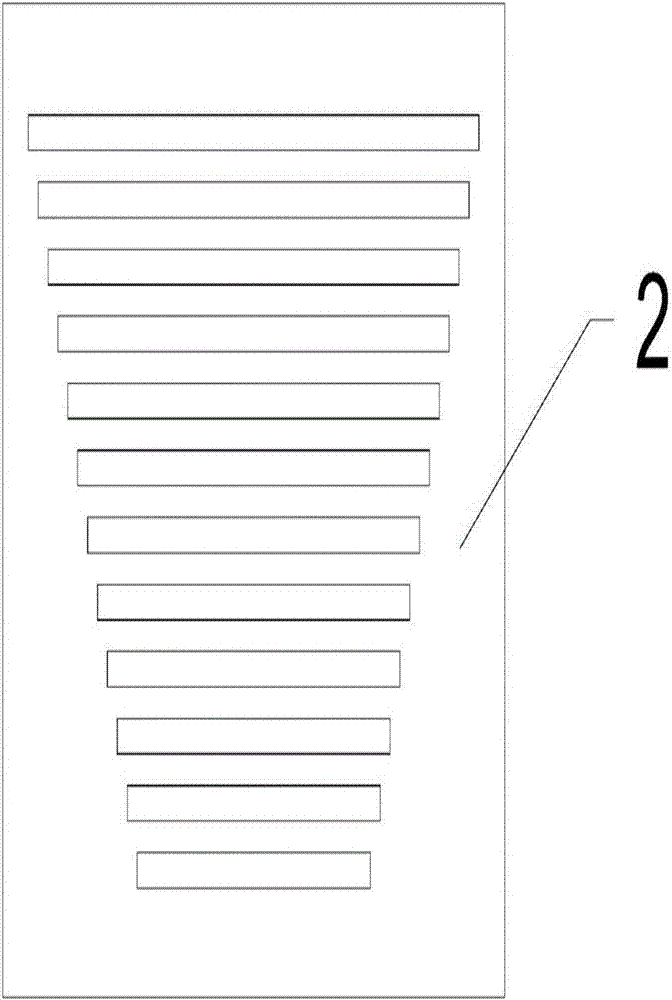

[0085] According to the distance of 3 meters, the billboard is vertically divided into 6 a×b rectangular lighting areas, where a is 3 meters and b is 6 meters. The floodlights of each design only need to meet the requirements of this 3m x 6m lighting area;

[0086] The light bracket is installed vertically on the bottom and top of the billboard (if installed at the bottom, the light will project upwards; if installed at the top, the light will project downwards). This example takes the installation at the bottom as an example. The effective length of the lamp bracket is set to v, that is, the vertical distance between the lens 4 plane of the floodlight and the plane of the billboard;

[0087] It is known that the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com