Ganoderma vinegar and brewing method thereof

A technology of Ganoderma lucidum and antlers, applied in the field of antlers Ganoderma lucidum vinegar and its brewing, can solve the problems of restricting the consumption capacity and consumption habits of high-end health care products, and the small market demand, so as to avoid a large amount of losses, low production costs, and simple technical solutions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

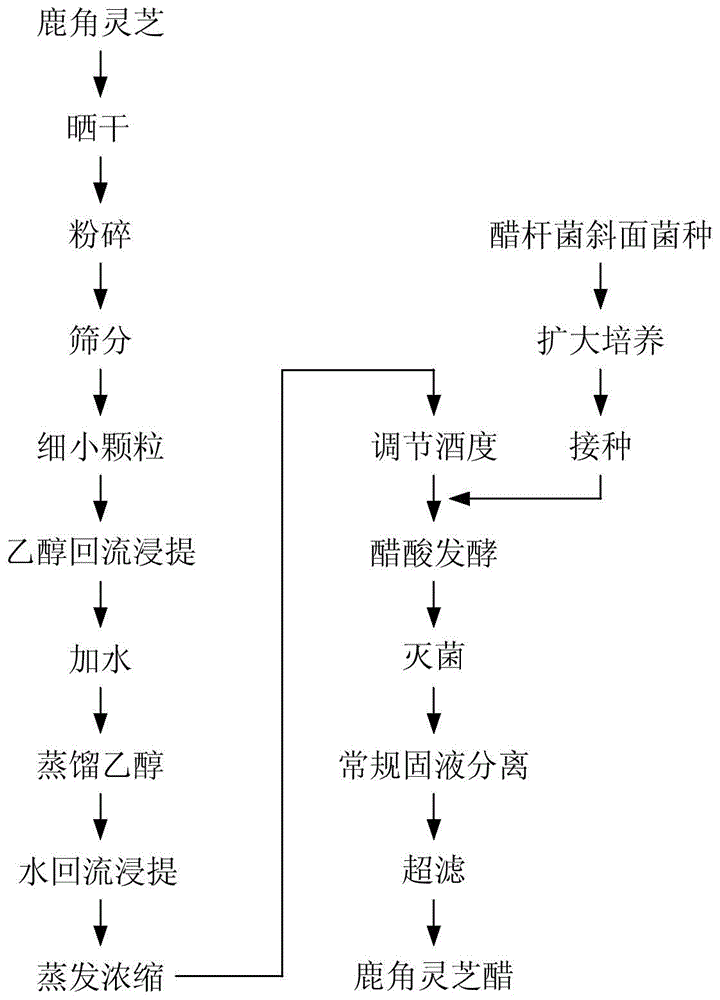

[0037] The brewing process of antler ganoderma vinegar is shown in Figure 1, and comprises the following steps:

[0038] (1) High-concentration ethanol solution extraction

[0039] The dried antler ganoderma was crushed and sieved with a 60-mesh sieve, and 0.5 kg of fine particles were taken, and 10 L of 70% (v / v) edible ethanol solution was added, and ultrasonic waves were used for crushing treatment. ℃ constant temperature reflux extraction for 60min; after extraction, add 10L of water, carry out ethanol distillation until the remaining volume is 10L, and obtain suspension I; the ethanol obtained by distillation is recovered.

[0040] (2) Water extraction

[0041] Place 10L of suspension I obtained above at 90°C for constant temperature reflux for leaching for 60 minutes, and then evaporate and concentrate until the volume of suspension I reaches 1.5L. At this time, the liquid-solid ratio is 3ml:1g, and suspension II is obtained.

[0042] (3) Acetic acid fermentation

[0...

Embodiment 2

[0048] (1) High-concentration ethanol solution extraction

[0049] The dried antler ganoderma was crushed and sieved with a 100-mesh sieve, 1.0 kg of fine particles were taken, 10 L of 90% (v / v) edible ethanol solution was added, and ultrasonic waves were used for crushing treatment. The treatment conditions were 400w and 30min, and then the ℃ constant temperature reflux extraction for 120min; after extraction, add 10L of water, carry out ethanol distillation until the remaining volume is 10L, and obtain suspension I; the ethanol obtained by distillation is recovered.

[0050] (2) Water extraction

[0051] Place 10L of suspension I obtained above at 100°C for constant temperature reflux extraction for 120min, then evaporate and concentrate until the volume of the suspension reaches 2L, and the liquid-solid ratio is 2ml:1g at this time to obtain suspension II.

[0052] (3) Acetic acid fermentation

[0053] The process of expanding the cultivation of acetic acid bacteria is as...

Embodiment 3

[0058] (1) High-concentration ethanol solution extraction

[0059] The dried antler ganoderma was crushed and sieved with a 100-mesh sieve, 1.0 kg of fine particles were taken, 15 L of 80% (v / v) edible ethanol solution was added, and ultrasonic waves were used for crushing treatment. ℃ constant temperature reflux extraction for 90 minutes; after extraction, add 15L of water, carry out ethanol distillation until the remaining volume is 15L, and obtain suspension I; the ethanol obtained by distillation is recovered.

[0060] (2) Water extraction

[0061] Place 15 L of the above-obtained suspension at 95°C for constant temperature reflux for leaching for 90 minutes, then evaporate and concentrate until the volume of the suspension reaches 3 L. At this time, the liquid-solid ratio is 3ml:1g to obtain Suspension II.

[0062] (3) Acetic acid fermentation

[0063] The process of expanding the cultivation of acetic acid bacteria is as follows: inclined plane → shake flask cultivatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com