A method for determining the degree of heating of shredded tobacco in convection drying

A technology of convective drying and convective heat transfer coefficient, which is applied in the direction of tobacco, prepared tobacco, moisture content of materials, etc., and can solve the problem that the single-point outlet temperature cannot accurately represent the heating of shredded tobacco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

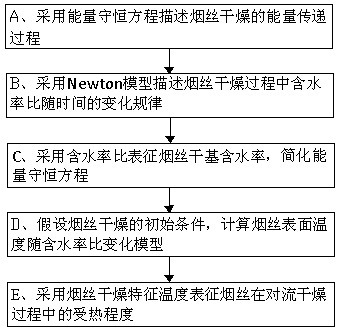

[0026] Such as figure 1 Shown, a kind of method for measuring the degree of heating of shredded tobacco in the convection drying of the present invention comprises the following steps:

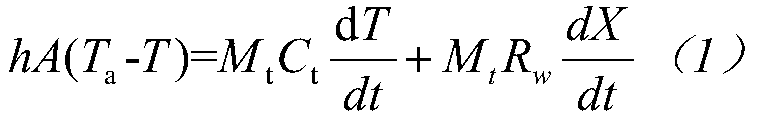

[0027] A. Assuming that the convective heat transfer coefficient, the effective area in contact between the cut tobacco and the drying medium and the specific heat capacity of the cut tobacco are constant during the drying process of cut tobacco, the energy transfer process of cut tobacco drying is described by the energy conservation equation:

[0028]

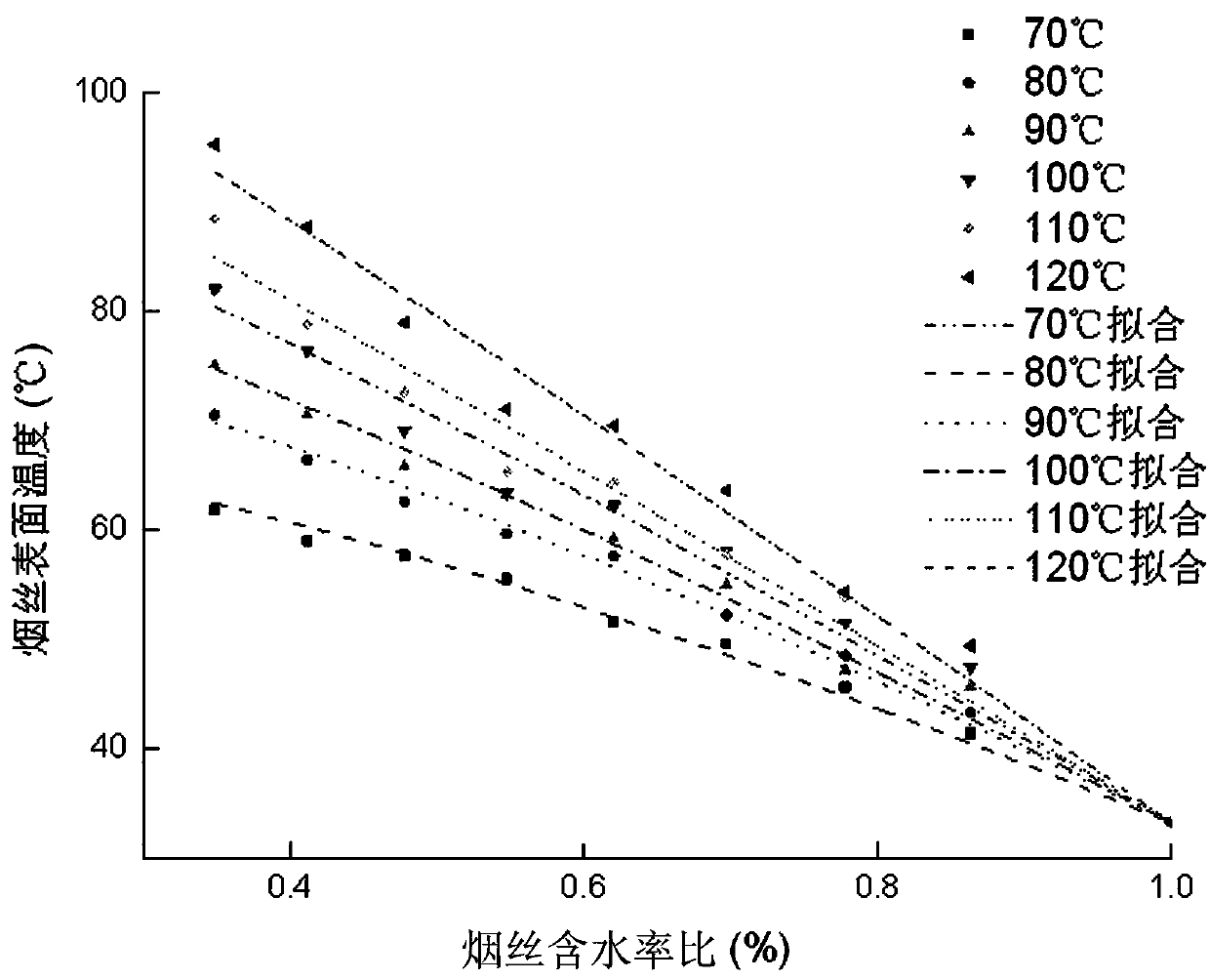

[0029] Where h—convective heat transfer coefficient [W / (m 2 .°C)]; A—the effective area of the shredded tobacco in contact with the hot air in the convective heat exchange (m 2 ); T a — drying medium dry bulb temperature (°C); T — tobacco surface temperature (°C); M t — mass of shredded tobacco (kg); C t - Specific heat capacity of shredded tobacco [J / (kg.℃)]; R w —Latent heat of vaporization of water (J / kg); X—moisture content of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com