Patents

Literature

53 results about "Moisture ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Moisture ratio. A moisture ratio compares an amount of air to an amount of moisture. A moisture ratio is a ratio that compares the mass or volume of air to the mass or volume of moisture contained in that air. In construction, it is an important consideration when designing a building for a certain climate.

Optical pressure-sensitive adhesive sheet, optical film and display device

ActiveUS20120100359A1Increased durabilityObscures visibilitySynthetic resin layered productsAmide/imide polymer adhesivesDynamic viscoelasticitySheet film

The present invention provides an optical pressure-sensitive adhesive sheet in which white turbidity is not caused by humidification and durability is excellent as well. The present invention provides an optical pressure-sensitive adhesive sheet, comprising: a pressure-sensitive adhesive layer in which a moisture ratio after storage under an environment of 60° C. and 95% RH for 120 hours is 0.65 wt % or more, and a shear storage elastic modulus at 85° C. which is measured by a dynamic viscoelastic measurement is 5.0×104 to 5.0×105 Pa, wherein a peeling distance measured by the constant-load peel test is 30 mm or less when an adherend is a polyethylene terephthalate plate, and the peeling distance measured by the following constant-load peel test is 30 mm or less when the adherend is an acrylic plate.

Owner:NITTO DENKO CORP

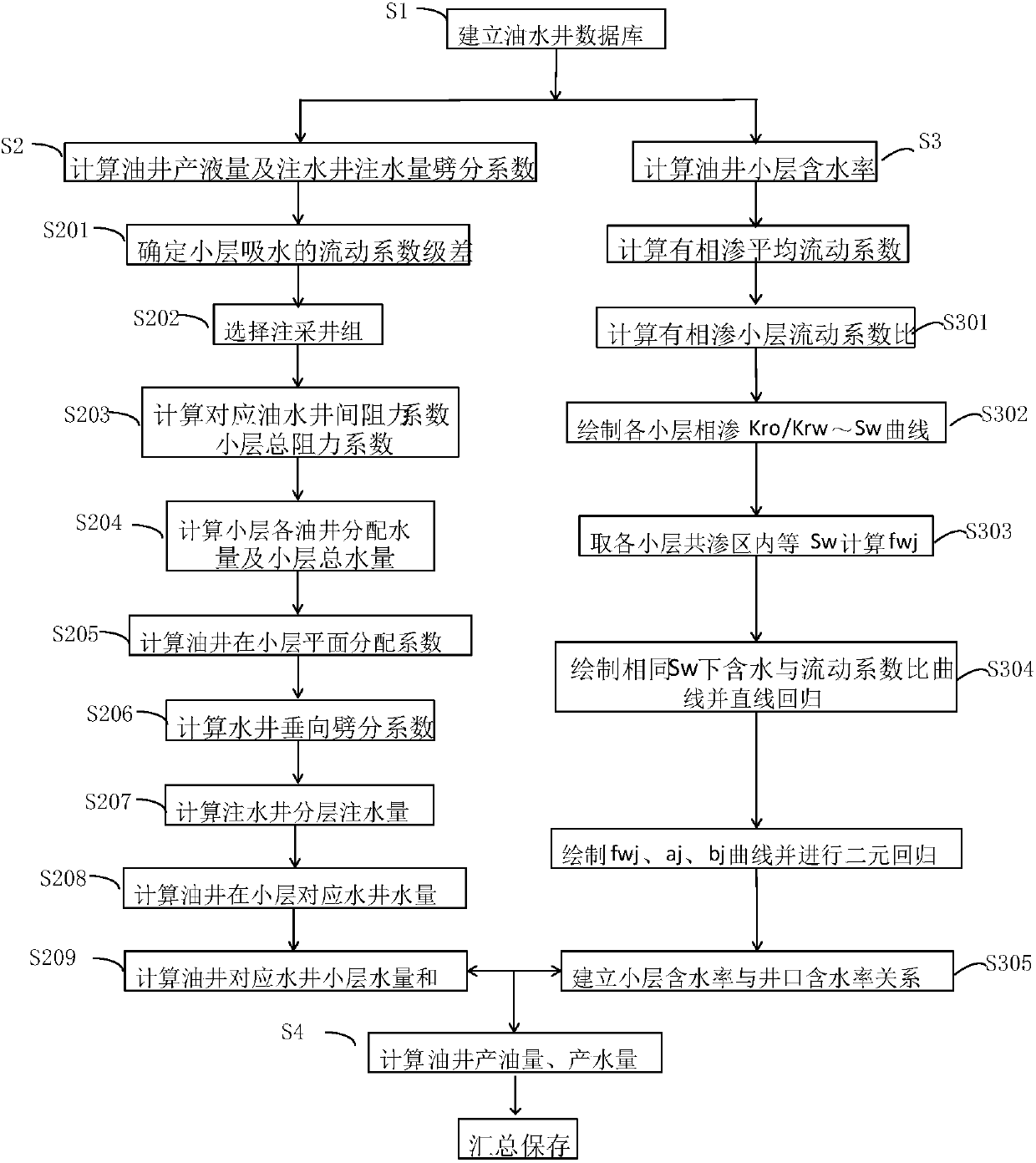

Oil-water well yield splitting method of injection-production balance principle

ActiveCN106777651ASplitting results are accurateDesign optimisation/simulationSpecial data processing applicationsWater productionOil water

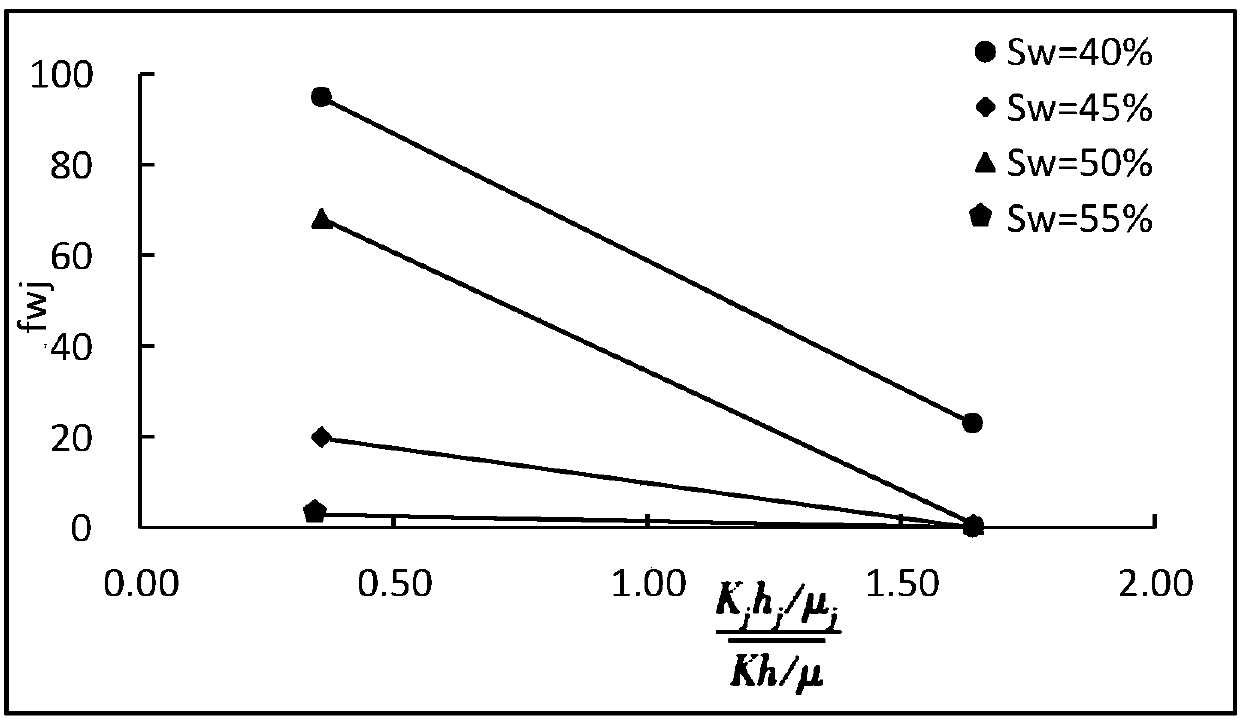

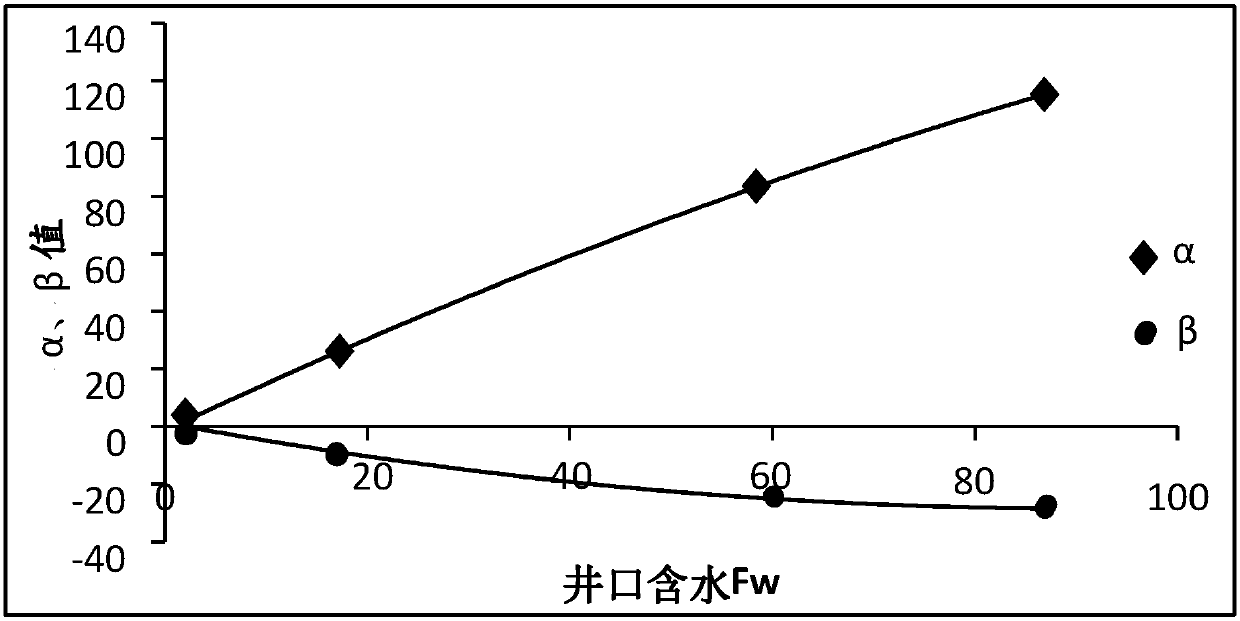

The invention provides an oil-water well yield splitting method of an injection-production balance principle. The oil-water well yield splitting method comprises the following steps: step S1, collecting oil-water well data and establishing an oil-water well database; step S2, calculating a fluid production amount of an oil well and a water injection amount splitting coefficient of a water injection well; step S3, calculating a single-layer moisture ratio of the oil well; and step S4, calculating the oil production amount and water production amount of the oil well according to calculation results of the step S2 and step S3, and gathering and storing. According to the method provided by the invention, a plurality of geological factors are comprehensively considered, and the water injection amount of the water injection well, and the oil production amount and water production amount of the oil well are split by taking a development block as a unit and the water injection well as the center; and in a process of splitting the yield of the water injection amount and the water injection amount of the water well, a non-water-absorbing layer is identified and eliminated and the splitting result of the water injection amount is more accurate.

Owner:北京源博科技有限公司

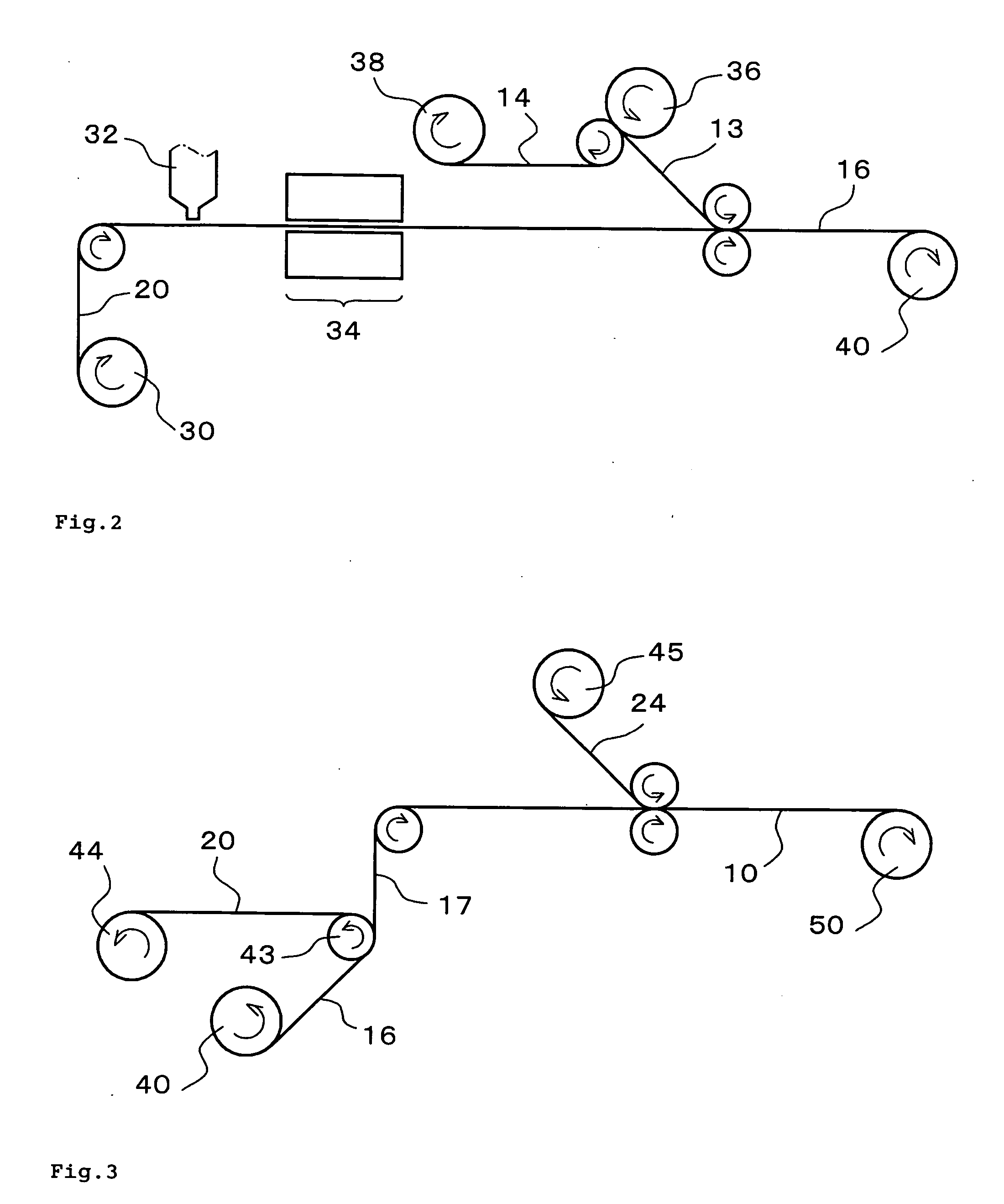

Method for producing complex phase retarder and complex optical member

InactiveUS20070056682A1Maintain adhesionLamination ancillary operationsLaminationOrganic solventAdhesive

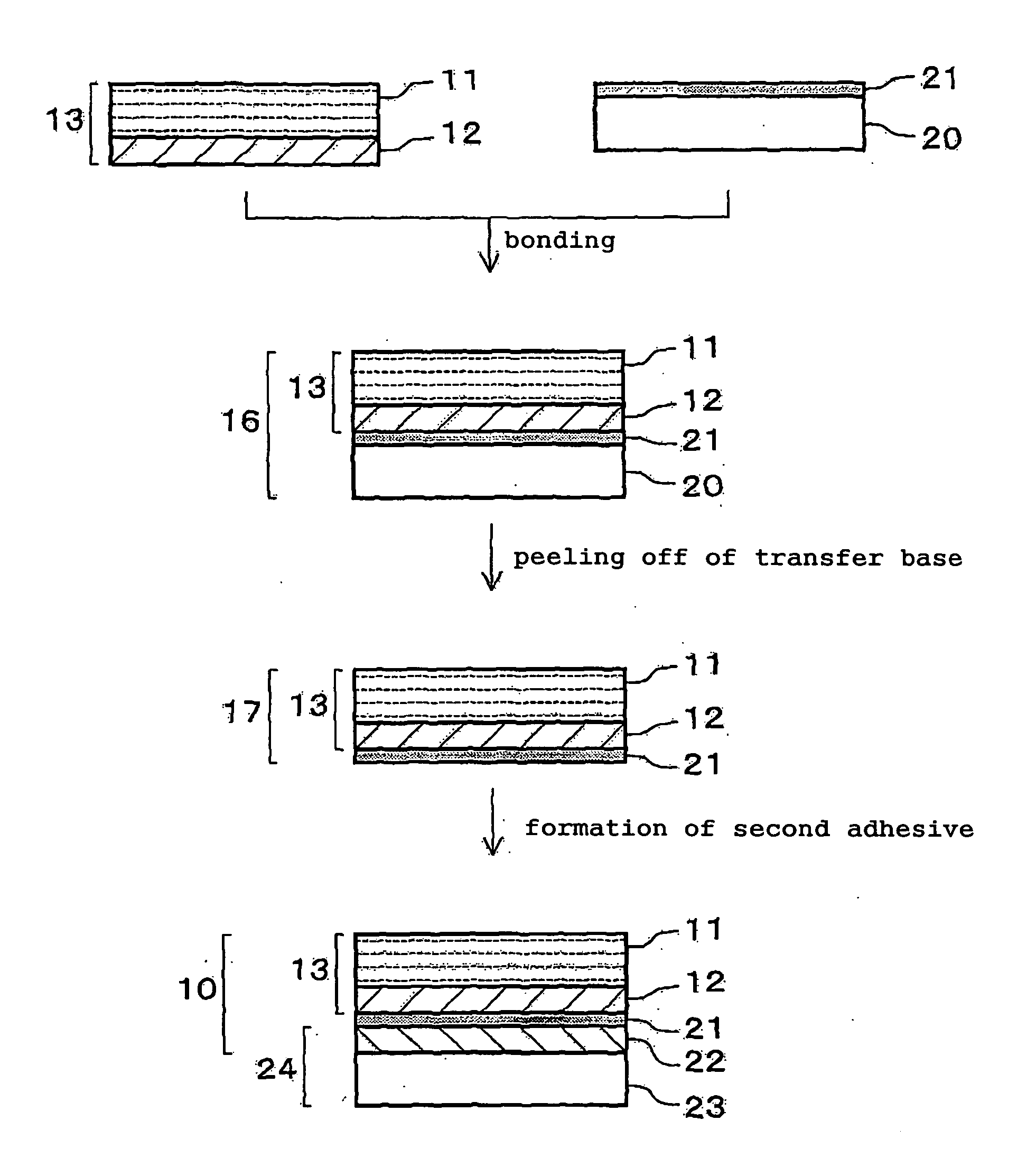

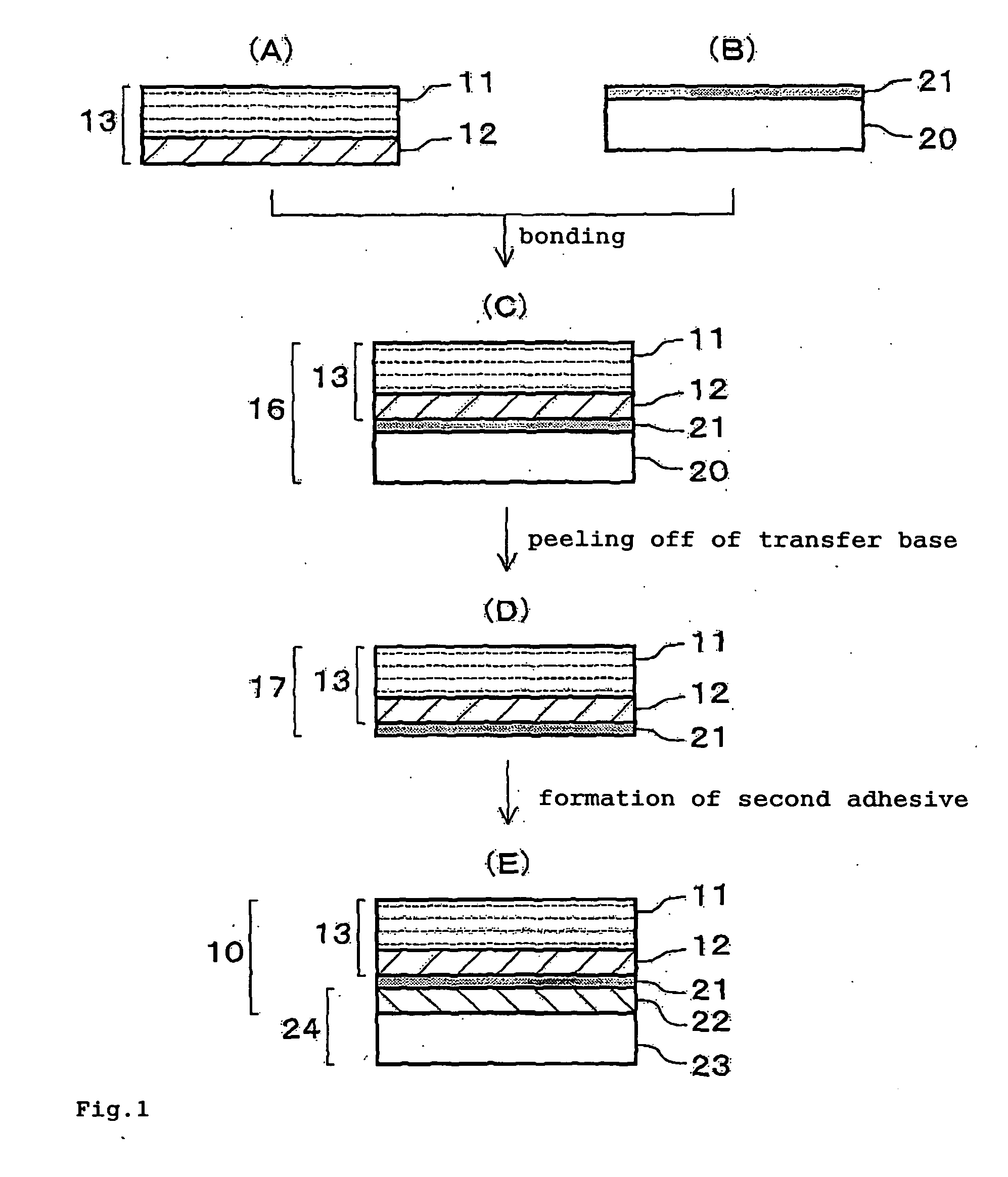

The present invention provides a method for producing a complex phase retarder comprising a first phase retarder of at least one resin film, an adhesive layer and a second phase retarder of a coating layer laminated in this order, the method comprising: preparing a phase retarder with an adhesive where an adhesive layer is formed on a surface of a first phase retarder; applying on a transfer base a coating liquid containing an organic modified clay compound of which the chlorine content is no greater than 2,000 ppm and a binder resin in an organic solvent where the moisture ratio measured using a Karl Fischer's moisture meter is 0.15 wt % to 0.35 wt %; forming a second phase retarder by removing the organic solvent and the water from the applied coating liquid; bonding an exposed surface of the above described second phase retarder to the adhesive layer side of the above described phase retarder with an adhesive; peeling the transfer base from the above described second phase retarder; and forming a second adhesive layer on the surface of this second phase retarder from which the transfer base was peeled.

Owner:SUMITOMO CHEM CO LTD

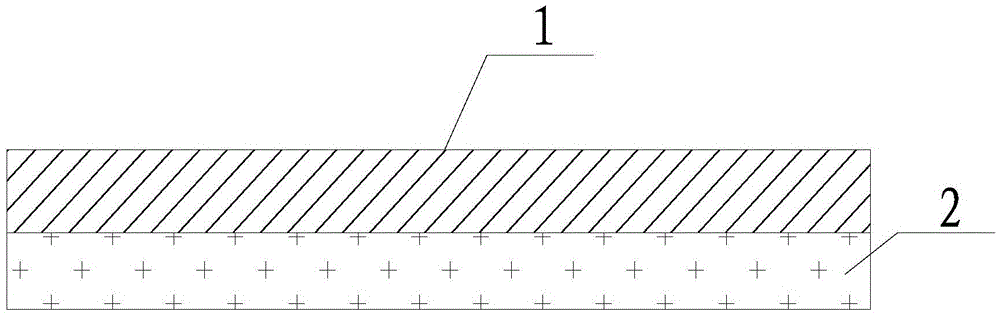

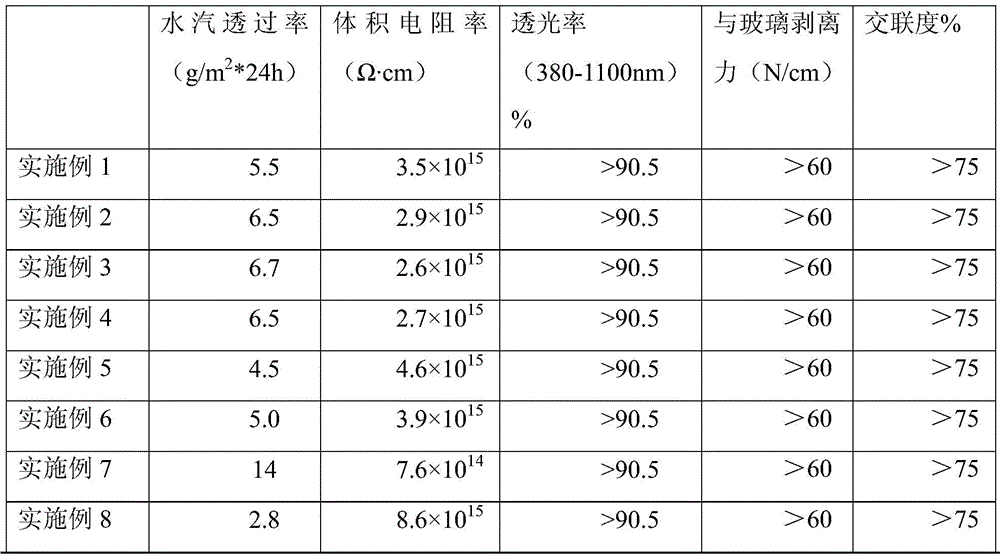

Laminated packaging film for solar cell and solar cell module with packaging film

ActiveCN105619986AImprove encapsulationImprove water vapor barrier performanceSynthetic resin layered productsPhotovoltaic energy generationPolyvinyl butyralElastomer

The invention relates to a laminated packaging film for a solar cell and a solar cell module with the packaging film. The laminated packaging film comprises a first resin layer and a second resin layer formed on any surface of the first resin layer, wherein the first resin layer is a poly(ethylene-vinyl acetate) layer or a polyvinyl butyral layer or an ionomer layer or a polyurethane layer, and the second resin layer is a polyolefin elastomer layer. As the first resin layer and the second resin layer are arranged in a stacked mode and made of different materials, and the second resin layer is a polyolefin elastomer layer, the packaging film has a good packaging function, and meanwhile the packaging film can be endowed with a high vapor barrier property, a low moisture ratio, high insulativity, PID resistance and other functions; in addition, the packaging film is low in cost and easy to popularize.

Owner:CYBRID TECHNOLOGIES INC

Method for making tartary buckwheat tea

InactiveCN103053743AImprove microcirculationPlay the role of skin care and beautyTea substituesPolygonum fagopyrumBlood pressure

The invention provides a method for making tartary buckwheat tea. The method comprises the steps of: 1) putting tartary buckwheat in a container and adding clean water in the container to soak the tartary buckwheat; 2) fishing the soaked tartary buckwheat out of water for a curing process and controlling the steaming temperature at 95-100 DEG C; 3) baking the cured tartary buckwheat rapidly until a moisture ratio is 15-20%; 4) spraying water on the surface of the baked tartary buckwheat and placing the tartary buckwheat for 20-30 min; 5) shucking the tartary buckwheat after the water spraying and the placement by adopting a huller; 6) baking the shucked tartary buckwheat; 7) screening the baked tartary buckwheat by using a 8-12 meshes sieve; and 8) frying the screened tartary buckwheat by using a frying device until the tartary buckwheat is gold yellow; and processing the fried tartary buckwheat into the tartary buckwheat tea after cooling. The tartary buckwheat tea made by the method disclosed by the invention has extremely good effects on reducing blood fat, reducing blood pressure, decreasing blood sugar, improving microcirculation of heart and cerebral vessels and the like, has a function of protecting and beautifying the skin, and is a green, totally natural and healthy beverage.

Owner:神农架绿源天然食品有限责任公司

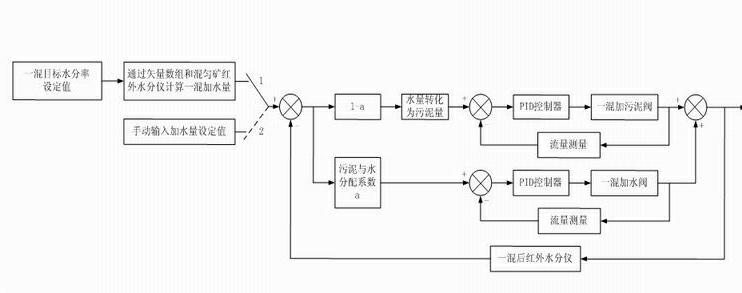

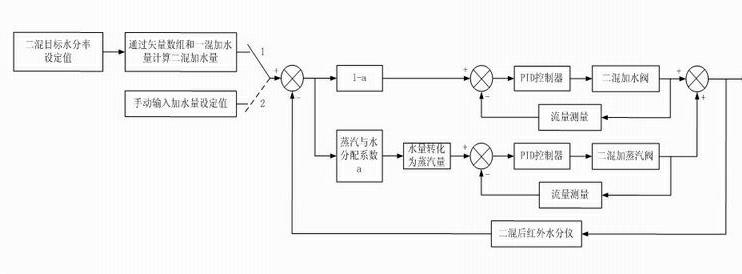

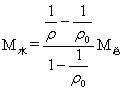

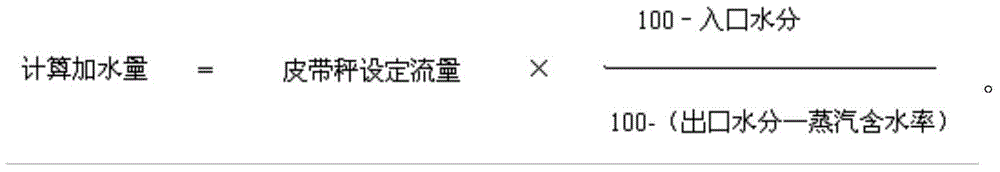

Control method for adding water in mixture in sintering production

InactiveCN102156486AResolve trackingSolve the problem of large lag in the processFlow control using electric meansSocial benefitsArray data structure

The invention relates to a control method for adding water in a mixture in sintering production, which is used for controlling the moisture ratio of the mixture so as to improve the yield and the quality of products, and belongs to the technical field of metallurgy sintering production control. The method comprises the following steps of: measuring the weight of each raw material, the flux of sludge, the density of the sludge, the flux of the added water and the added vapor and the moisture content of each raw material in real time; filtering the measured values, and calculating and judging the slaking degree of lime; creating a material tracking array, and calculating the moisture content before mixing; allocating and controlling the quantity of sludge and the water to be added in a first mixing process; and allocating and controlling the quantity of the vapor and the water to be added in a secondary mixing process according to the quantity of water added in the first mixing process, the moisture ratio measured after the first mixing process and a target value of the secondary mixing process. The mixture humidity control technology for a sintering machine provided by the invention is fast in reaction speed, high in control precision and capable of efficiently making good use of industrial waste to make waste profitable, so that an optimal mixture humidity control scheme of the sintering machine is provided for the iron and steel metallurgical enterprises, and the method can be generalized in the sintering machines of the same type and has excellent economic and social benefits.

Owner:WEIER AUTOMATION CO LTD TANGSHAN IRON & STEELGRP +2

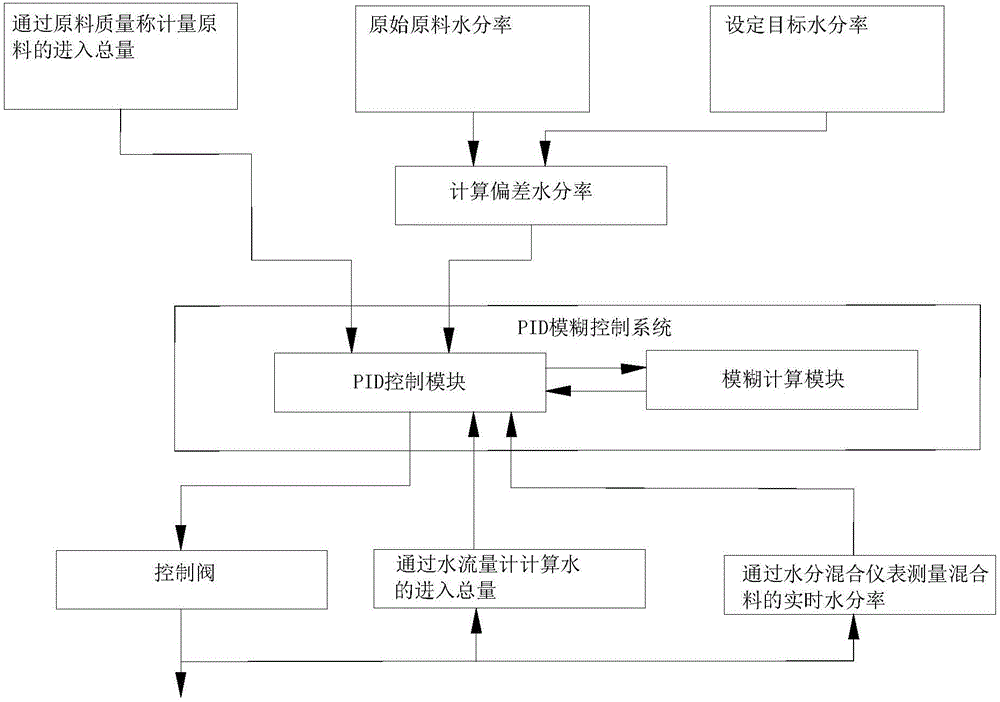

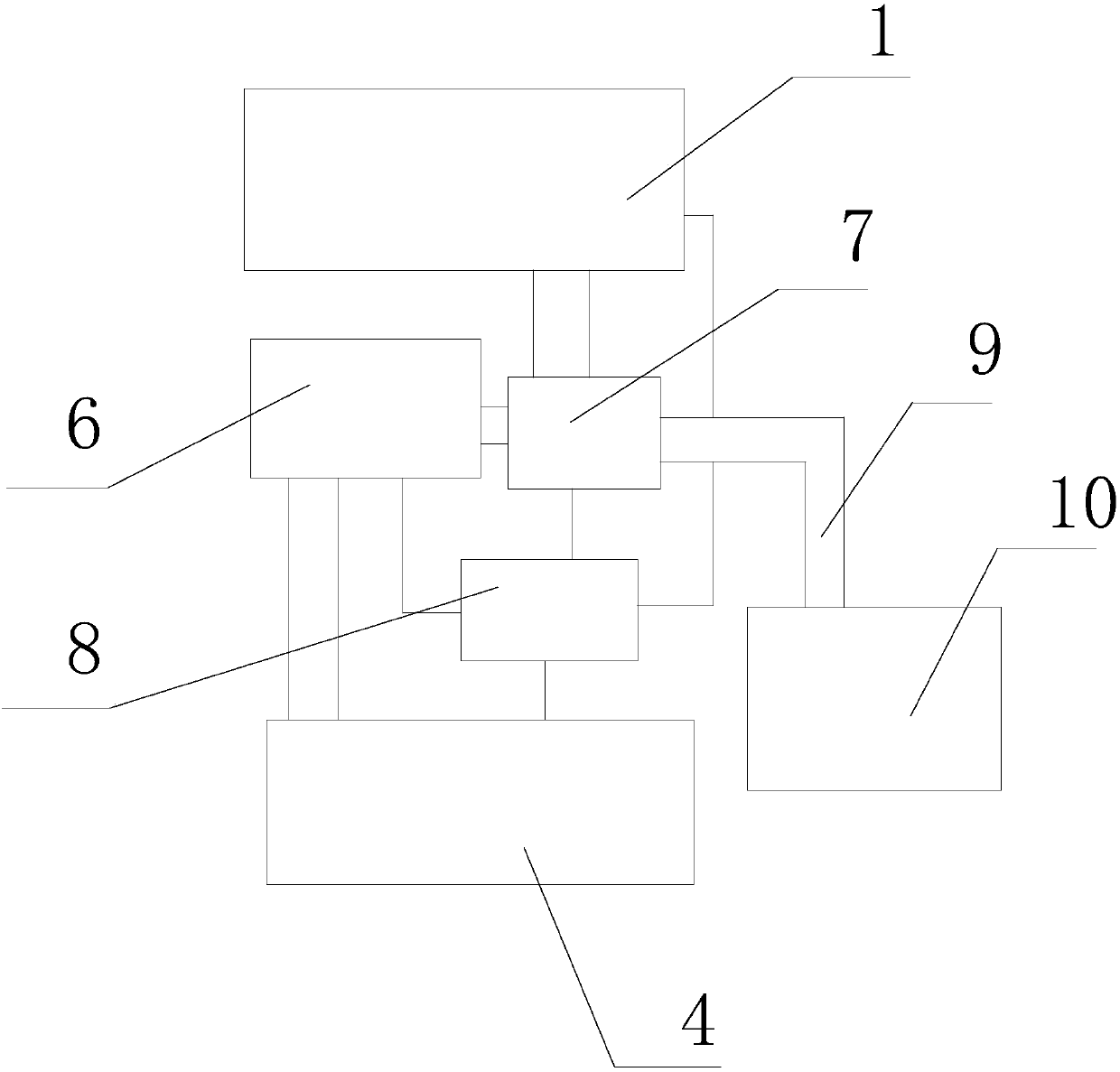

Control method for adding water into mixture of sintering machine

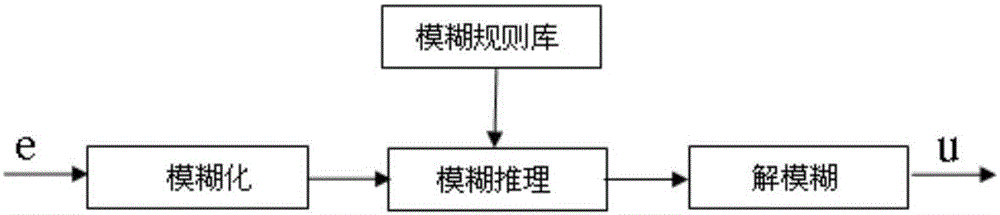

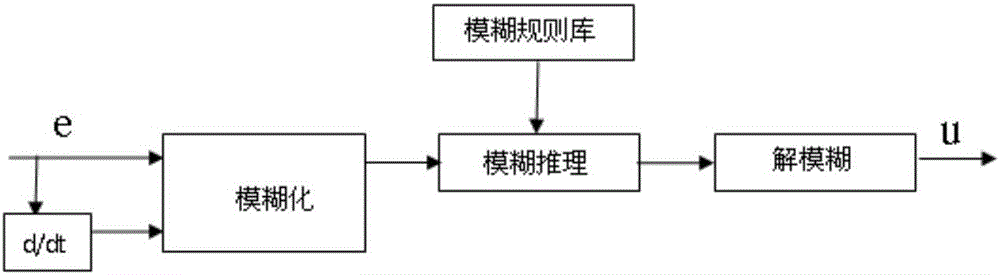

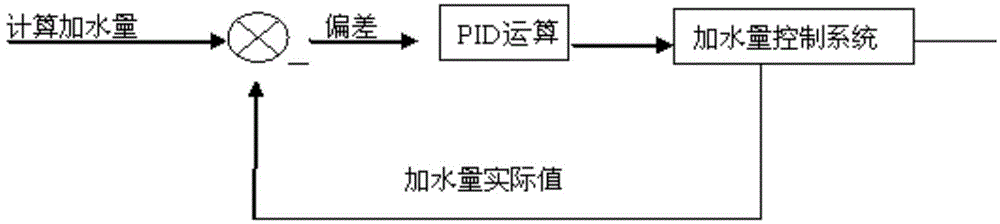

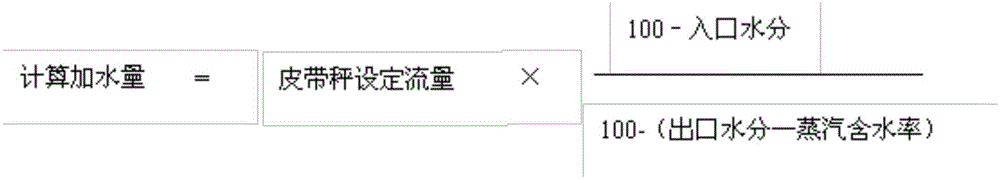

ActiveCN106444361ASolve the problem of mixing and adding water lagHigh precisionControllers with particular characteristicsFuzzy computingProportion integration differentiation

The invention relates to the technical field of water adding into mixtures of sintering machines and especially discloses a control method for adding water into a mixture of a sintering machine. The control method comprises the following steps of first, setting a target moisture ratio of the mixture according to the application of the mixture, feeding raw materials into a transmission area at a plurality of feeding points, metering the total inlet amount of the raw materials by a raw material mass weigh, and metering the total inlet amount of water by a water flowmeter; and arranging a plurality of mixed moisture instruments for tracking measurement points in a mixing area, so as to measure a real-time moisture ratio of the mixture. A PID (Proportion Integration Differentiation) fuzzy control system connected with the mixed moisture instruments, the raw material mass weigh and the water flowmeter comprises a PID control module and a fuzzy computing module, a set value of the water adding volume is obtained through calculation and fuzzy processing for data of the moisture ratio of the mixture, the mass of the raw materials, the target moisture ratio and the water adding mass which are received in real time, so as to realize the accuracy control for the water adding volume of the mixture. The problem that a control way of adding water into a mixture is lagged behind in the prior art is solved.

Owner:BEIJING ARITIME INTELLIGENT CONTROL

High-yield cut tobacco drying method

InactiveCN104432456AIncrease moisture contentReduce generationTobacco preparationManufacturing technologyPulp and paper industry

The invention relates to the technical field of cut tobacco making method, in particular to a high-yield cut tobacco drying method. The high-yield cut tobacco drying method solves the technical problems that in the prior art, due to the fact that when production starts, the drying capacity of a cut tobacco drier is much larger that the actual drying capacity needed by cut tobacco, much dry-head cut tobacco is generated, and the quality of the cut tobacco is poor. The high-yield cut tobacco drying method comprises the steps that when production starts, cut tobacco is accumulated on a conveyer belt in front of an inlet of a cut tobacco dryer, so that the instantaneous flow rate of the cut tobacco entering a material head of the cut tobacco dryer is increased; a material head water feeding delay correcting function is started in a super casing drum at a front-end procedure of the cut tobacco machine, the moisture ratio of the material head is increased instantly, the duration of the moisture ratio is controlled within reasonable duration, and the moisture ratio of the material head reaches a high value instantly. By the adoption of the high-yield cut tobacco drying method, the quality of the cut tobacco can be easily improved, and the amount of dry-head cut tobacco at an outlet of the tube-sheet cut tobacco drier is reduced.

Owner:CHINA TOBACCO SHAANXI IND

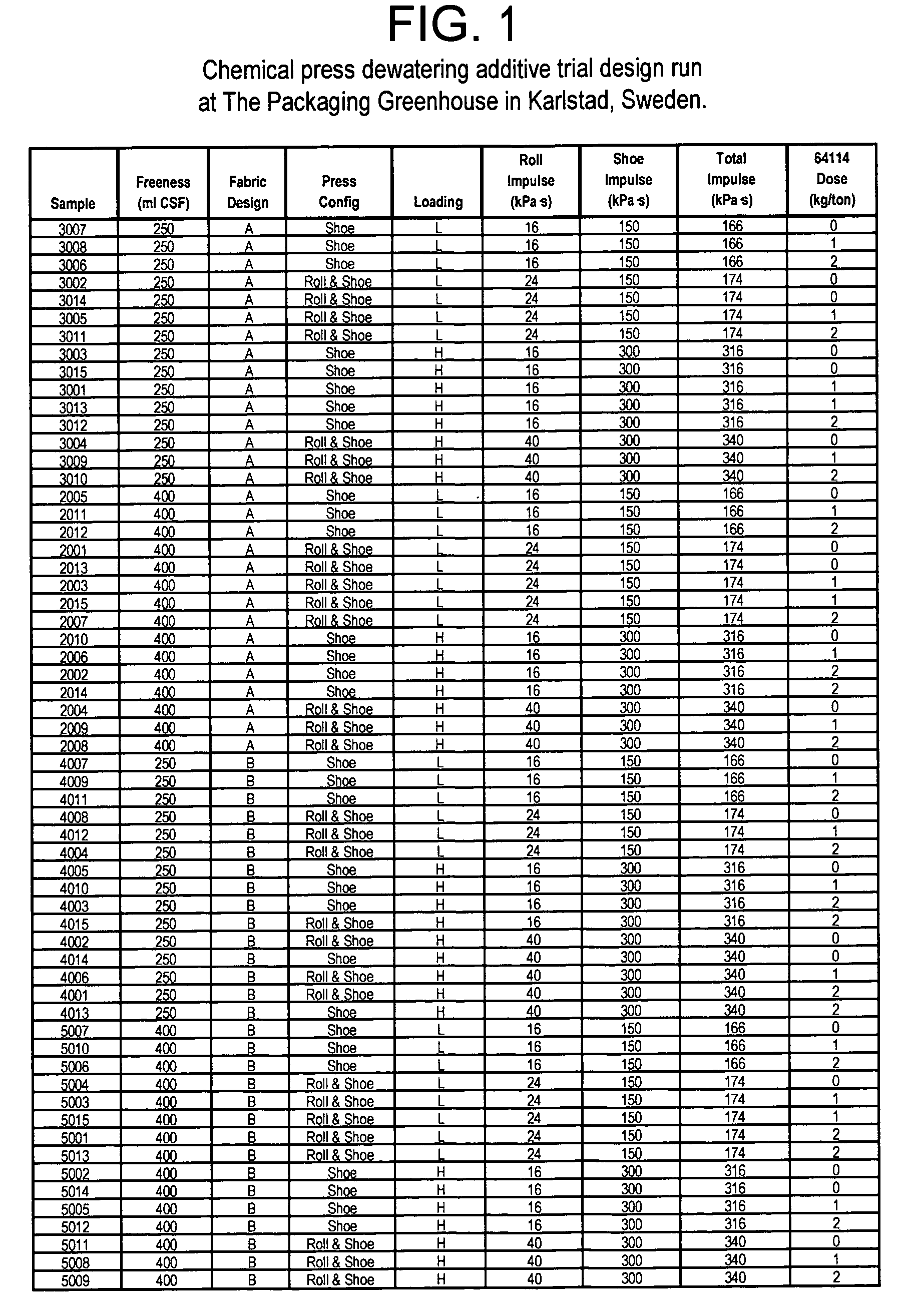

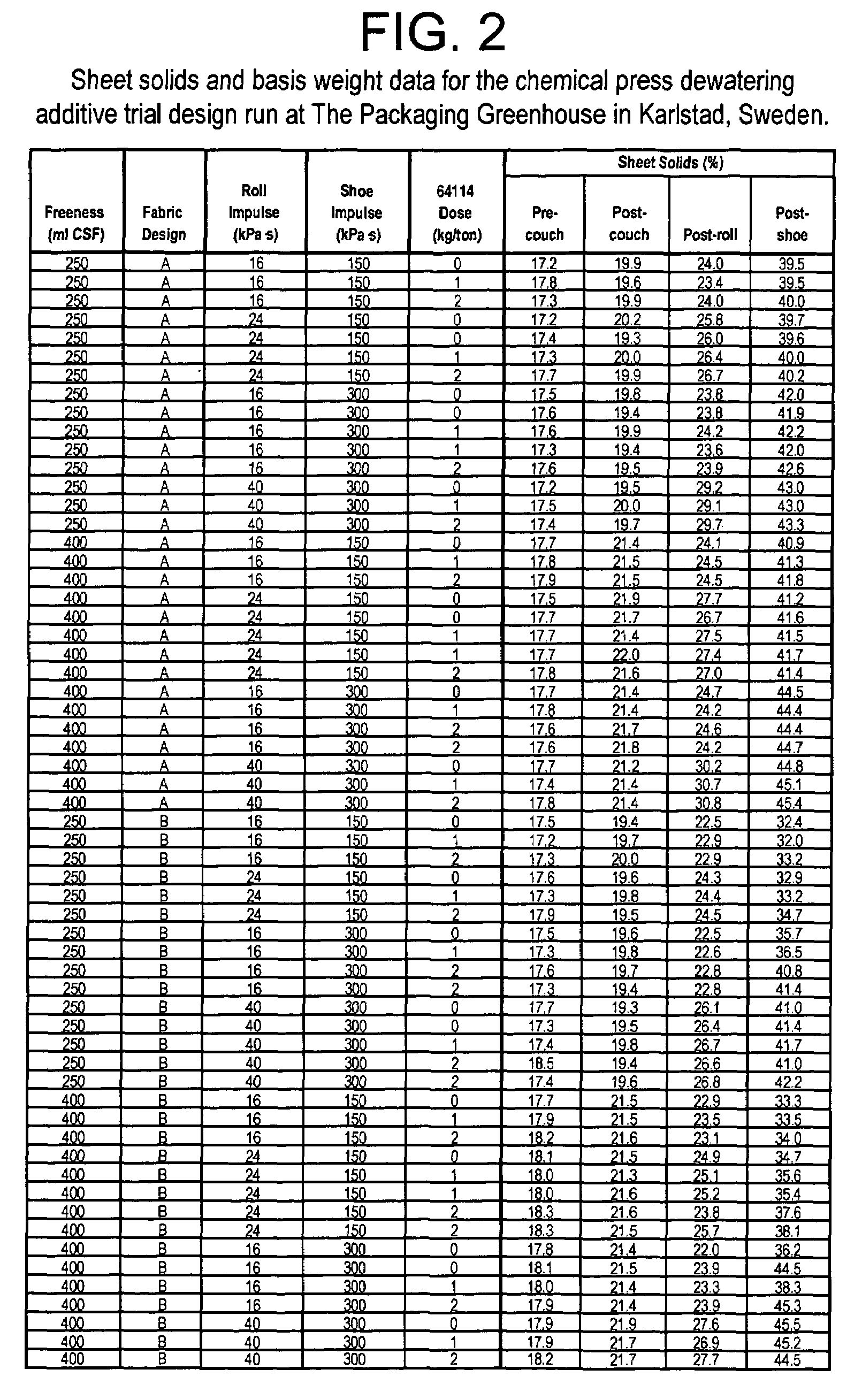

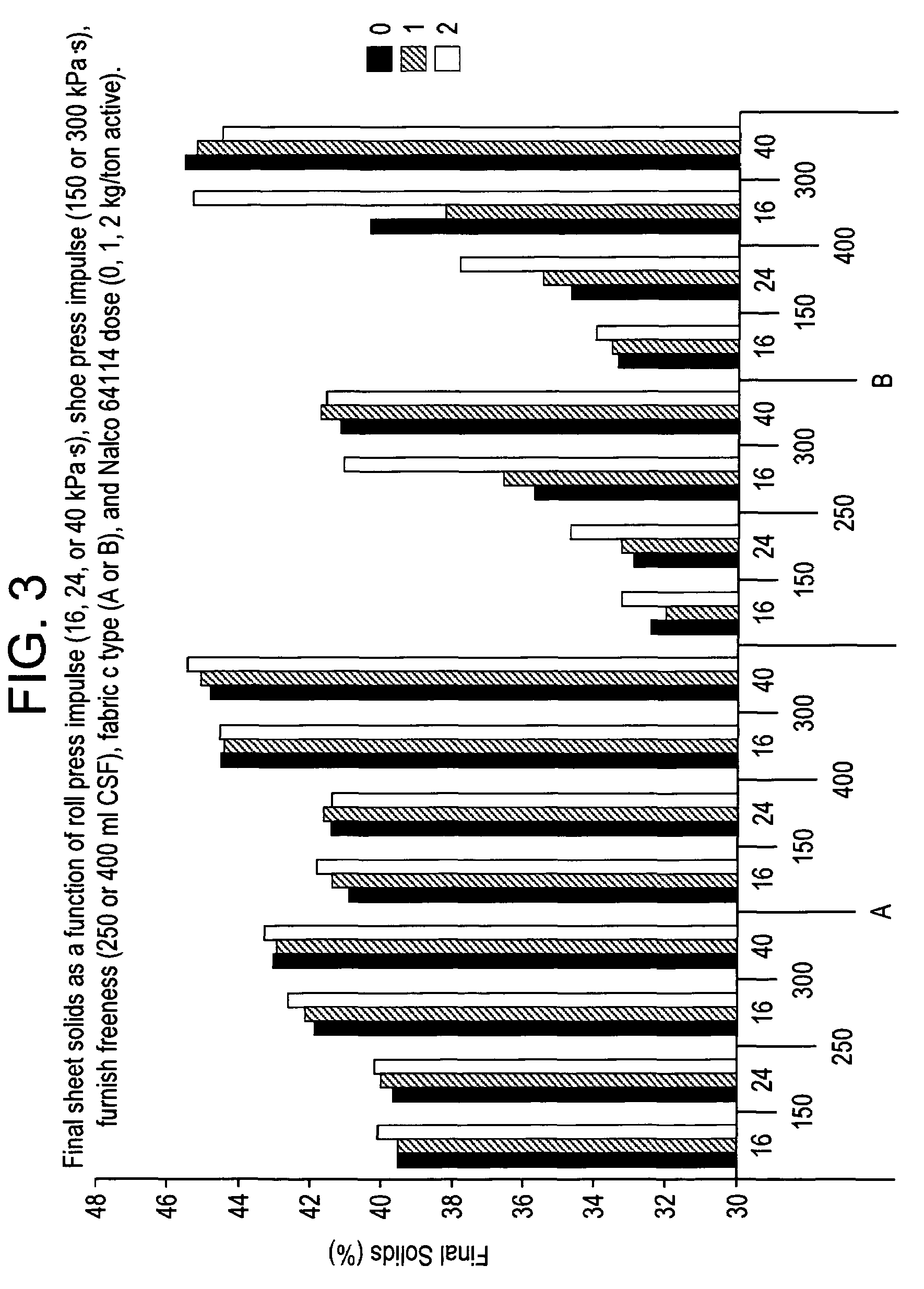

Method of operating a papermaking process

ActiveUS7556714B2High solid contentDigital differential analysersPress sectionPapermakingSolid content

A method of operating a papermaking process containing a press section with at least one press nip is disclosed. The method comprises simultaneously performing the following steps: (a) providing a press media for said papermaking process that has a MFP size that is less than the MFP size of a press media that was originally supplied to said papermaking process; (b) adding an effective amount of one or more press sheet dewatering additives to said papermaking process prior to the last press nip of said papermaking process; (c) providing a sheet moisture ratio of a paper sheet entering a press nip of said press section to between about 2 to about 9; and (d) applying an optimum rate of pressure development at one or more press nips of said papermaking process, wherein said steps a, b, c, and d either: result in the production of a more uniform paper sheet without the reduction in paper solids exiting the press section that would be expected from performing a, c, and d, alone or in combination with one another; or result in the production of a more uniform paper sheet with an increase in solids content of said paper sheet exiting the press section.

Owner:ALBANY INT CORP +1

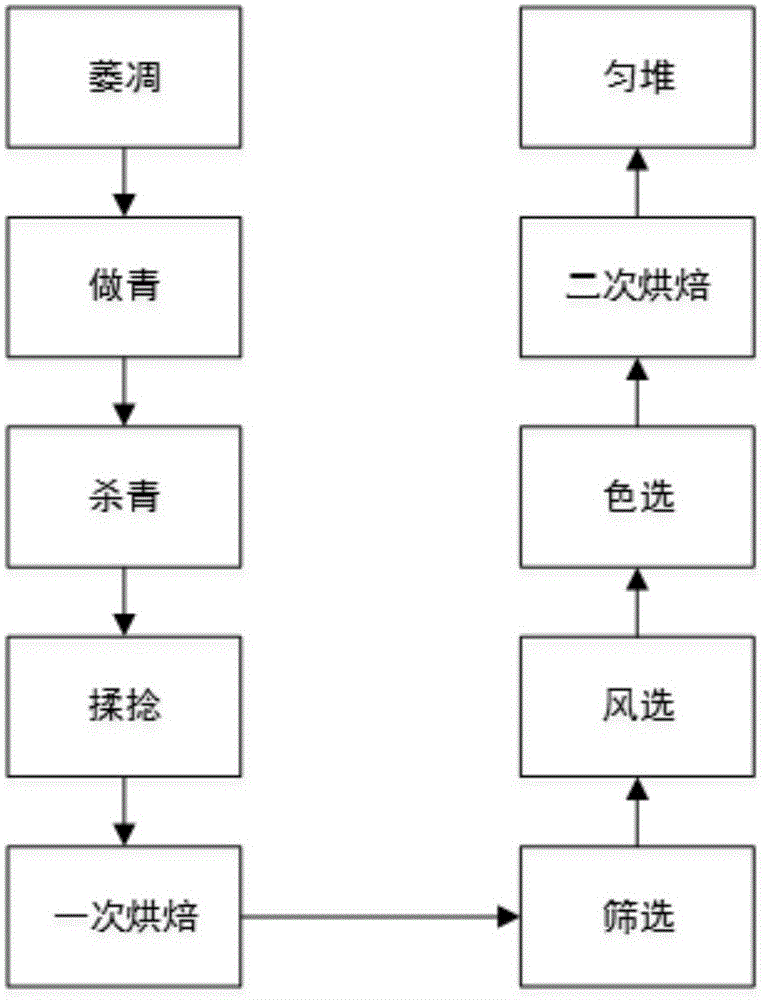

Process for making Wuyi rock tea

InactiveCN104605040AReduce inputImprove the level ofPre-extraction tea treatmentCooking & bakingGreen tea

The invention provides a making process capable of realizing automatic production of Wuyi rock tea. The process sequentially comprises the following steps: withering, performing fine manipulation of green tea leaves, performing fixation, rolling, performing primary baking, screening, winnowing, performing color sorting, performing secondary baking and performing blending mixing. With the adoption of the process for making Wuyi rock tea, standardization and automation can be realized, the investment of personnel is greatly reduced, the product safety is improved, and the product quality is stabilized. Meanwhile, unpleasant smell of the tea produced by adopting the conventional process is unlikely to be formed, and the moisture ratio of the tea leaves is conveniently controlled, so that the tea grade is greatly improved, and the production cost is directly reduced by 20-30 percent.

Owner:李方

High-moisture-ratio quick-setting filling material as well as preparation method and use method thereof

InactiveCN104230276AHigh water-solid ratioHigh volume moisture contentUltimate tensile strengthGypsum

The invention discloses a high-moisture-ratio quick-setting filling material which is prepared from the following raw materials in parts by weight: master batch including 90-94 parts of aluminate cement and 6-10 parts of an additive, and auxiliary materials including 65-85 parts of modified gypsum, 15-35 parts of quick lime and 2-4 parts of a coagulation accelerator. The filling material is high in water-solid ratio, good in hydrophilicity, short in gel time, quick in early strength enhancement, slow in later strength enhancement, good in flowability and pumpability, nontoxic and harmless, and can meet the requirements of mine filling.

Owner:河北充填采矿技术有限公司

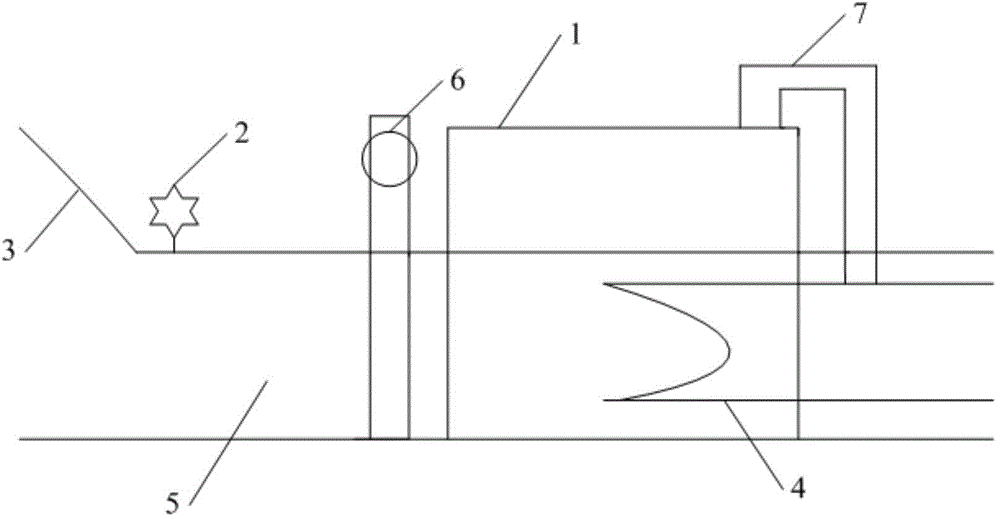

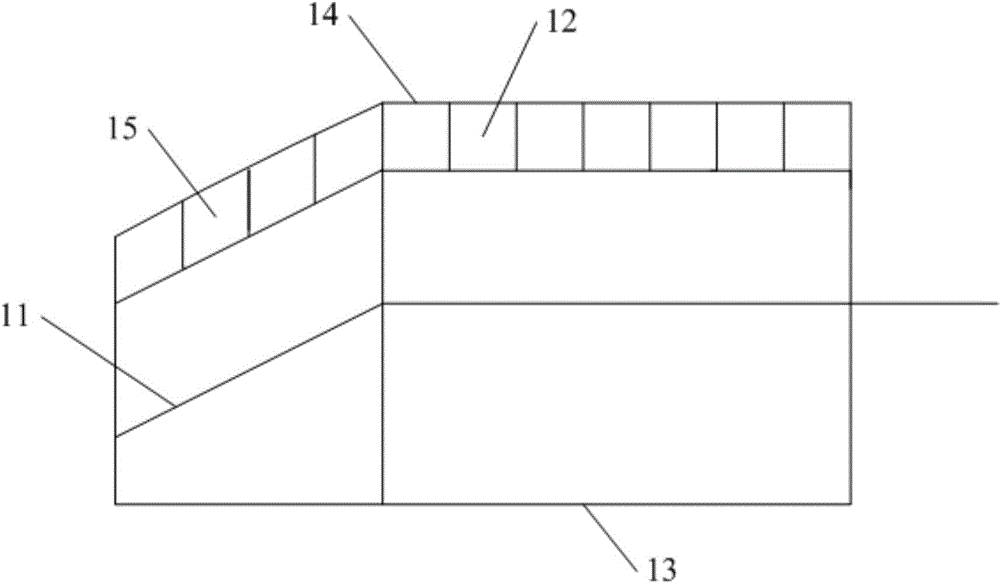

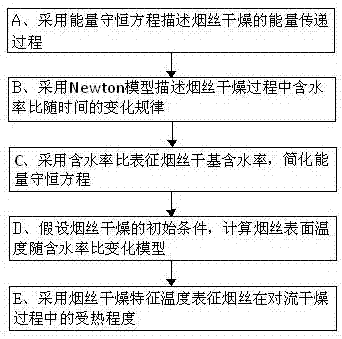

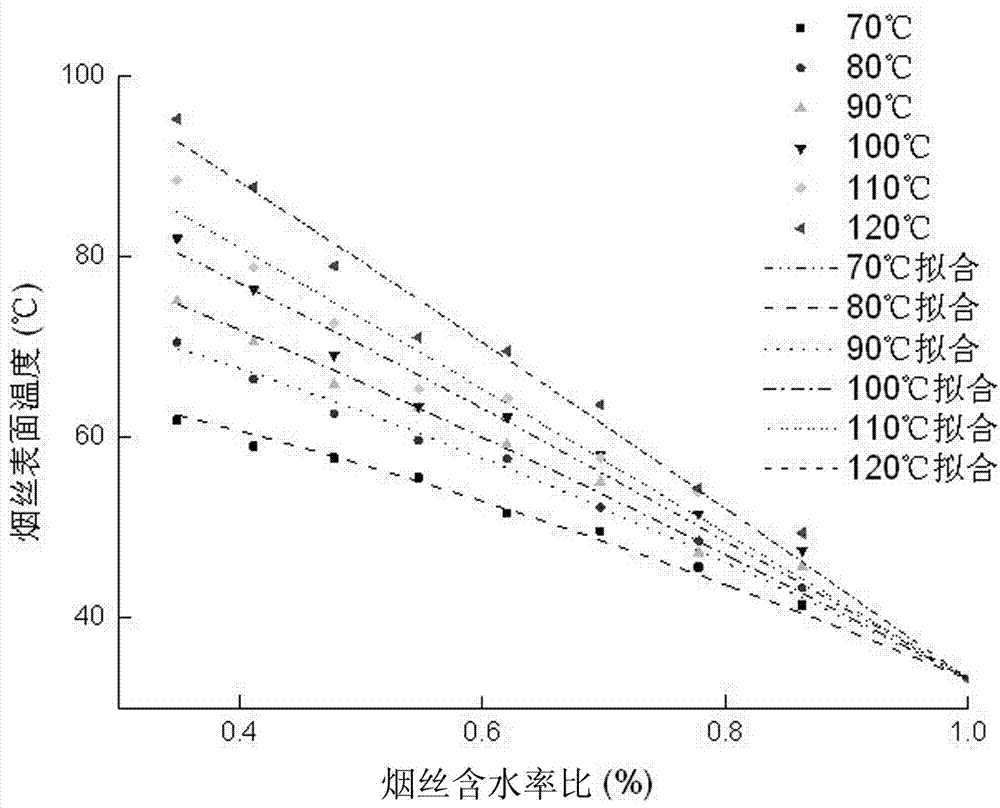

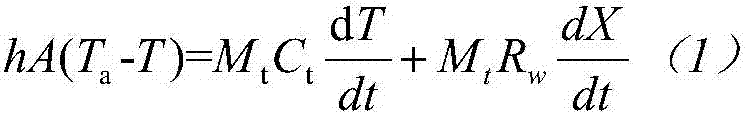

Convection drying tobacco heated degree measuring method

ActiveCN107462598ADescribe the heatTobacco preparationMaterial moisture contentEnergy transferProcess engineering

The invention discloses a convection drying tobacco heated degree measuring method. The convection drying tobacco heated degree measuring method comprises the following steps of A, describing the energy transfer process of tobacco drying through energy conservation equation; B, describing the change rules of moisture ratio to time during a tobacco drying process; C, representing dry-basis tobacco moisture by moisture ratio to simplify the energy conservation equation; D, assuming initial conditions of tobacco drying to computing a change model of tobacco surface temperature to moisture; E, representing the heated degree of tobacco during a convection drying process by tobacco drying characteristic temperature. The convection drying tobacco heated degree measuring method can accurately describe the heated conditions of the tobacco during the convection drying process and provide a basis for further research on rules of influence of tobacco heated degree on tobacco quality.

Owner:CHINA TOBACCO HENAN IND

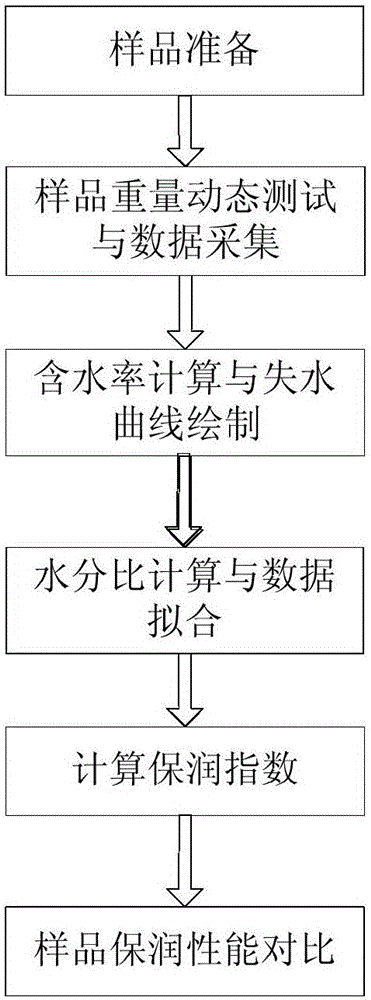

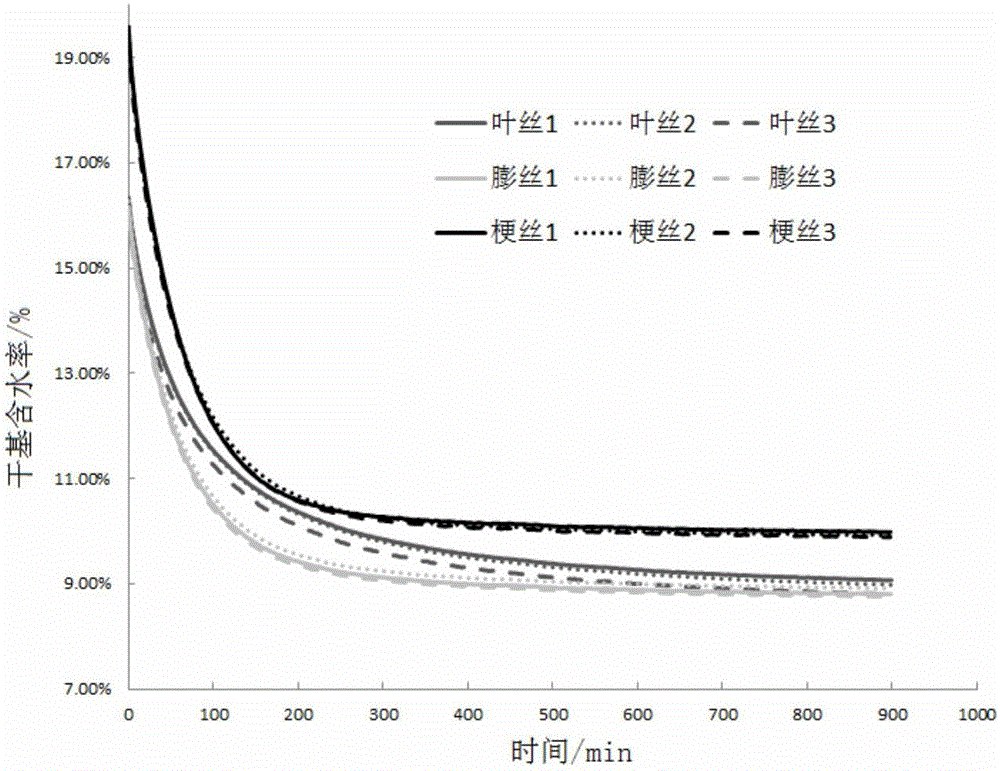

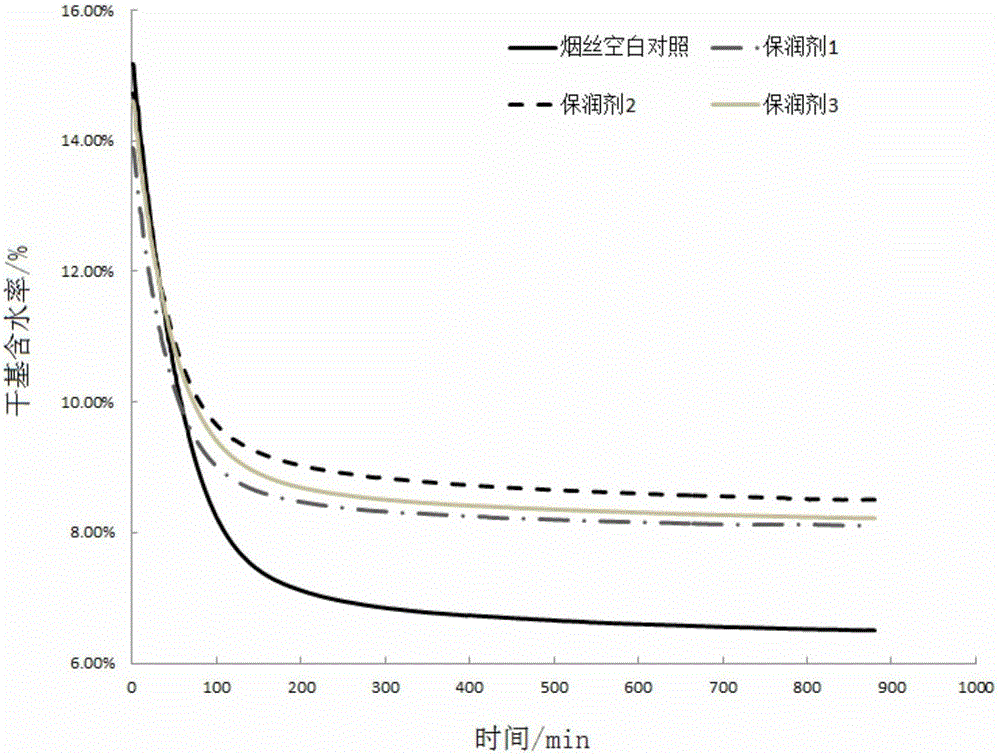

Tobacco moisture retention performance test method

ActiveCN105842103ACreativeShorten the test cycleWeighing by absorbing componentLoss rateData acquisition

The invention provides a tobacco moisture retention performance test method which comprises the steps of sample preprocessing, sample weight dynamic testing and data acquisition, dry base moisture rate calculation and moisture loss curve drawing, moisture ratio calculation and data fitting, and calculation of the moisture retention index and the average moisture loss rate or calculation of the average moisture loss rate at specific moisture ratio and the moisture retention index. The invention provides the tobacco moisture retention performance test and evaluation method which is used for solving the problems in the prior art that the tobacco shred moisture retention performance cannot be rapidly, simply, accurately and comprehensively tested and evaluated. Based on a fact that the tobacco physical moisture retention performance has relatively strong correlation with thermodynamics and kinetics indexes, the moisture retention evaluation method takes thermodynamic and kinetic indexes into account simultaneously, so that the tobacco physical moisture retention performance is more comprehensively and scientifically evaluated.

Owner:SHANGHAI TOBACCO GRP CO LTD

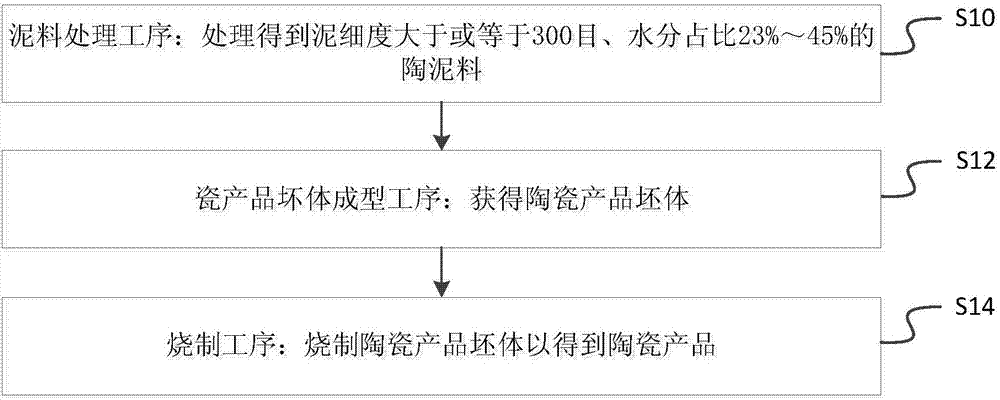

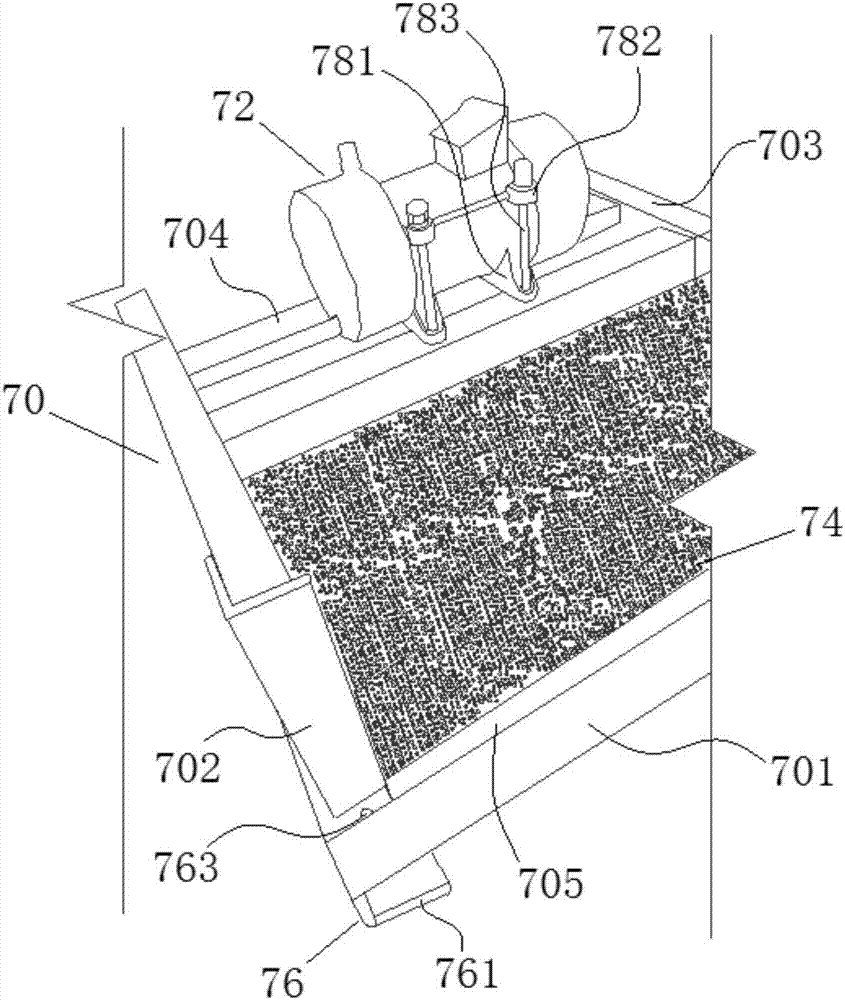

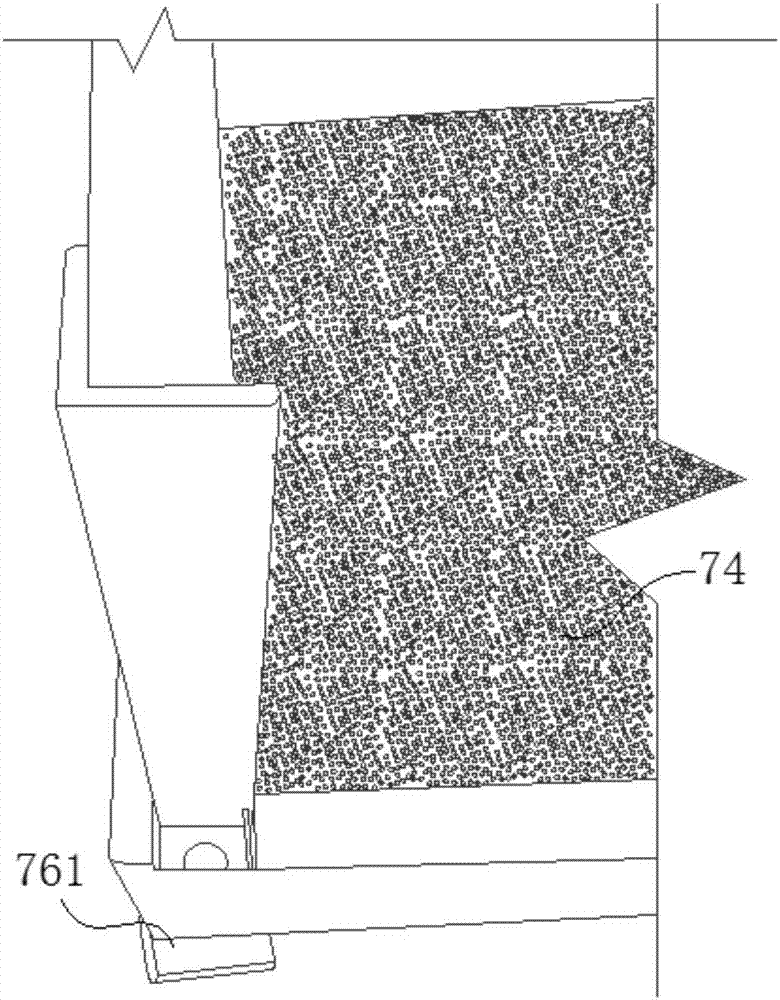

Manufacturing technology of non-glaze ceramic products

InactiveCN107379207AImprove compactnessGuaranteed compactnessCeramic shaping apparatusClay processing apparatusManufacturing technologyMetallurgy

The invention discloses a manufacturing technology of non-glaze ceramic products. The manufacturing technology comprises the following steps that S10, a clay treatment process is carried out, wherein treatment is carried out to obtain a clay material with the clay fineness larger than or equal to 300 meshes and the moisture ratio ranging from 23% to 45%; S12, a ceramic product blank molding process is carried out, wherein ceramic product blanks are obtained; and S14, a firing process is carried out, wherein the ceramic product blanks are fired to obtain the ceramic products. The step S10 comprises the following sub-steps that S101, clay selection is carried out, wherein clay with the clay content larger than or equal to 98% and the high-temperature resistance larger than or equal to 1200 DEG C is selected; S102, the clay is processed to obtain needed fineness, wherein the clay obtained in the step S101 is processed to obtain the clay material with the fineness larger than or equal to 300 meshes; and S103, moisture in the clay material is drained, wherein the vacuumized clay material with the moisture ratio ranging from 23% to 45% is obtained for standby application. The compactness of the ceramic products obtained through the above technology can be guaranteed without glazing, and the original ecology of the ceramic products is better achieved.

Owner:重庆市民益陶瓷有限公司

Method for producing poliarization substrate

InactiveCN101387717AEfficient manufacturingSynthetic resin layered productsPolarising elementsPolyvinyl alcoholCellulose acetate

The invention provides a method of manufacturing a polarizing plate, over an adhesive layer, a cellulose acetate type resin film is laminated on one surface of a polarized light film made of polyvinyl alcohol type resin, and a cycloolefin type resin film is laminated on the other surface over the adhesive layer, thereby manufacturing the polarizing plate, characterized in that, before laminating the cellulose acetate type resin film and the cycloolefin type resin film, moisture ratio of the polarized light film maintains at more than 8 weight percent, and after laminating the cellulose acetate type resin film and the cycloolefin type resin film, strain keeps less than 600 N / m. The method can restrain defects of the polarizing plate, which is formed through laminating the cellulose acetate type resin film on one surface of the polarized light film made of polyvinyl alcohol type resin over the adhesive layer, and laminating cycloolefin type resin film on the other surface over the adhesive layer.

Owner:SUMITOMO CHEM CO LTD

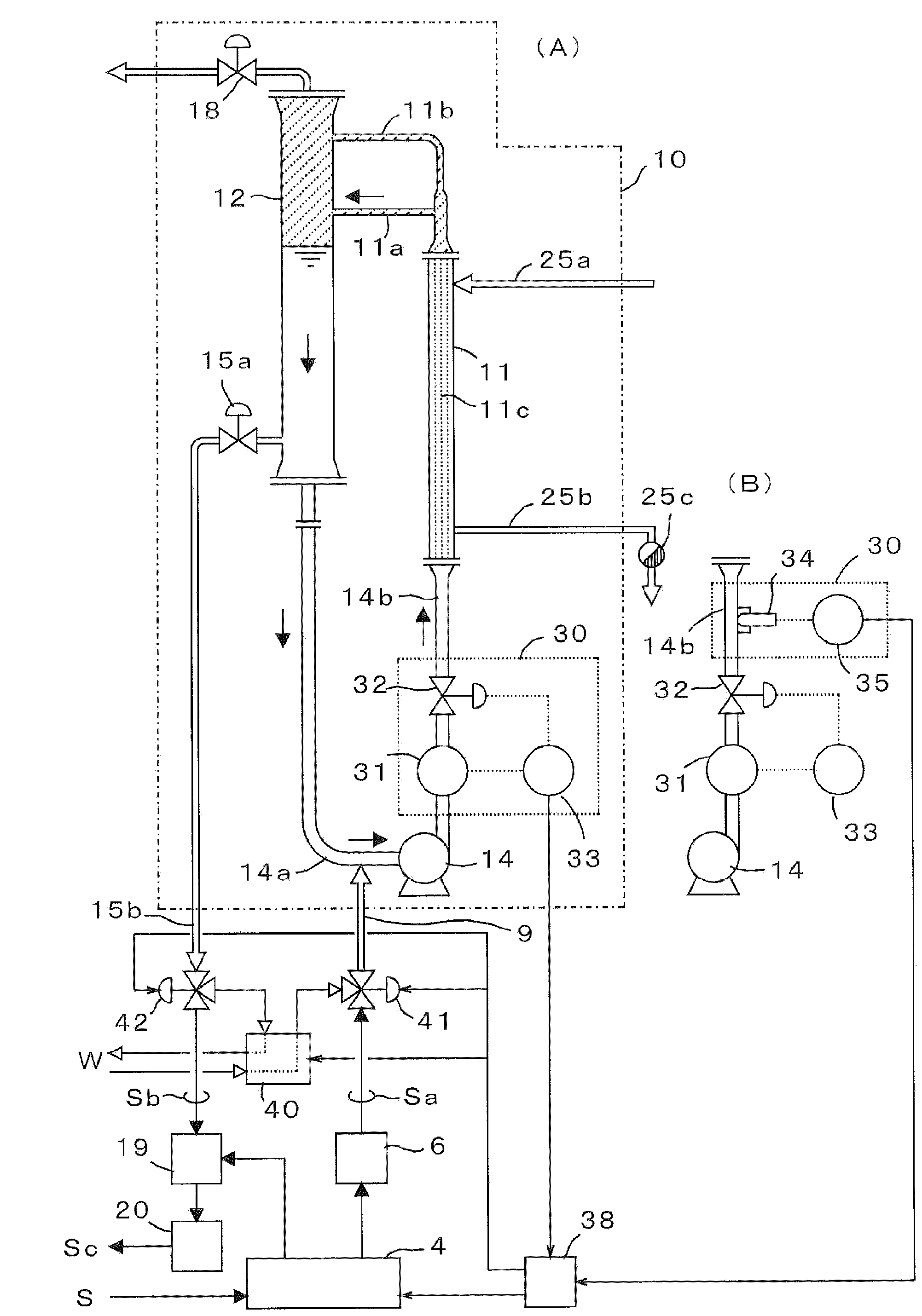

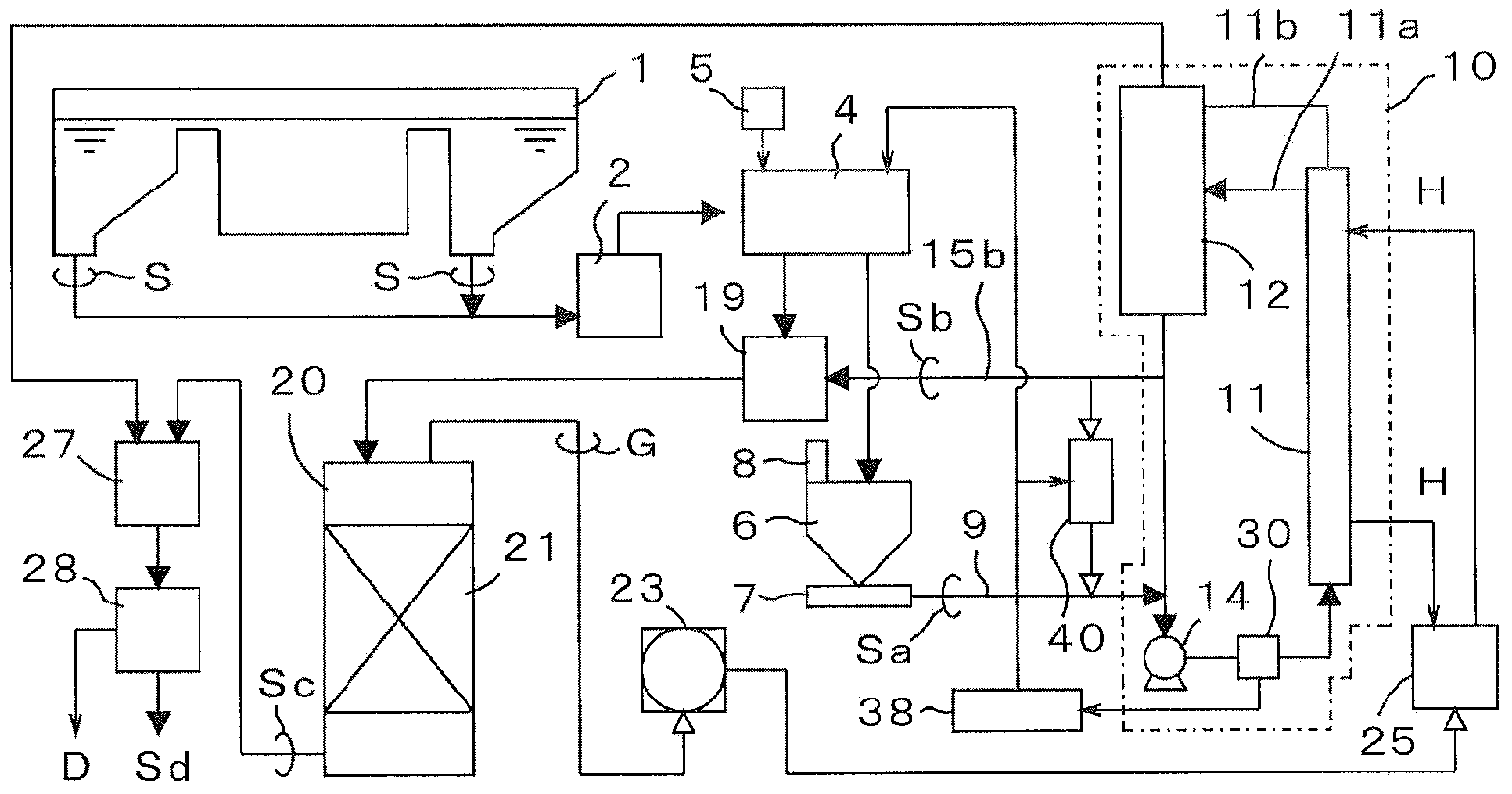

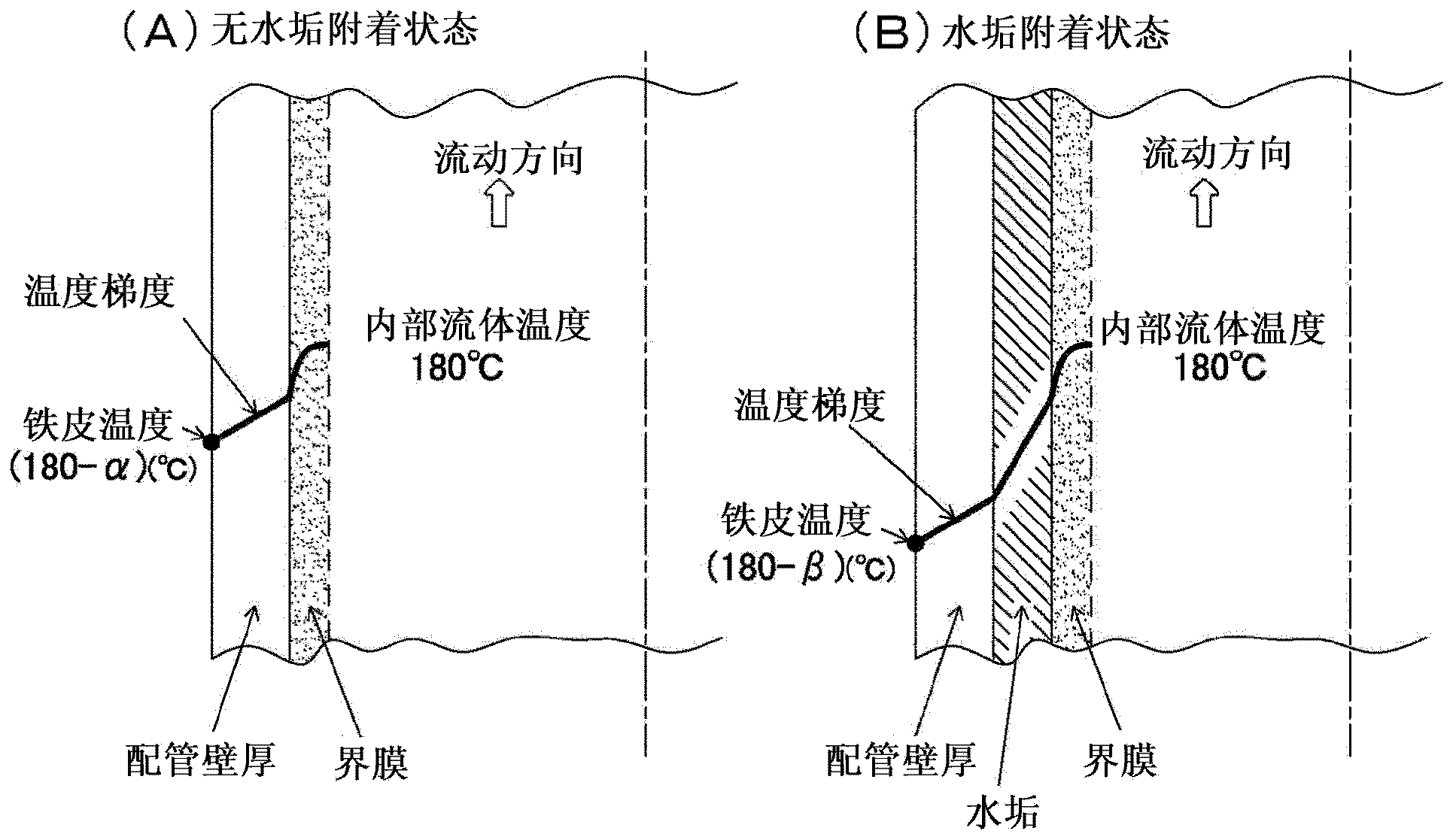

Method and system for methane fermentation processing of sludge using hydrothermal reactions

InactiveCN103547537AGood guessInhibit growthWater treatment parameter controlSludge treatment by oxidationVapor–liquid separatorSludge

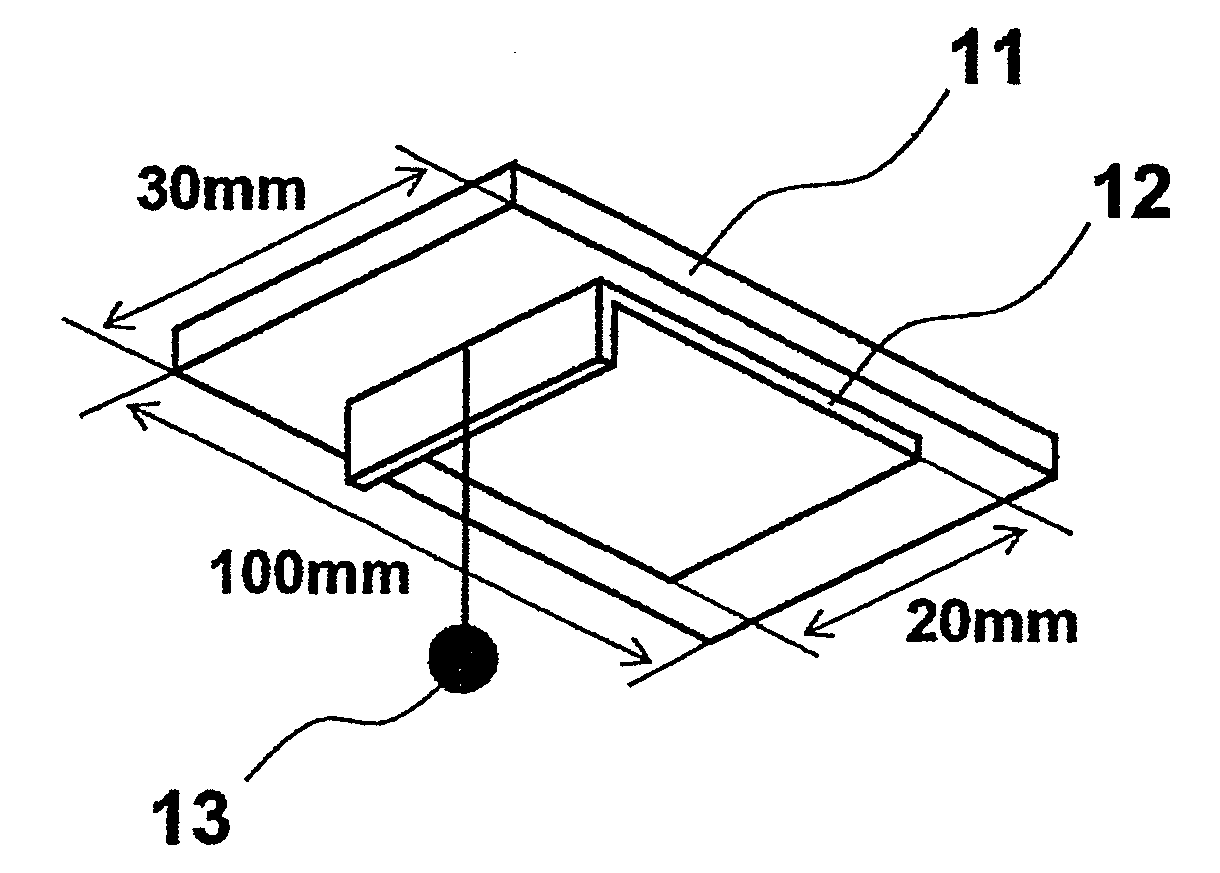

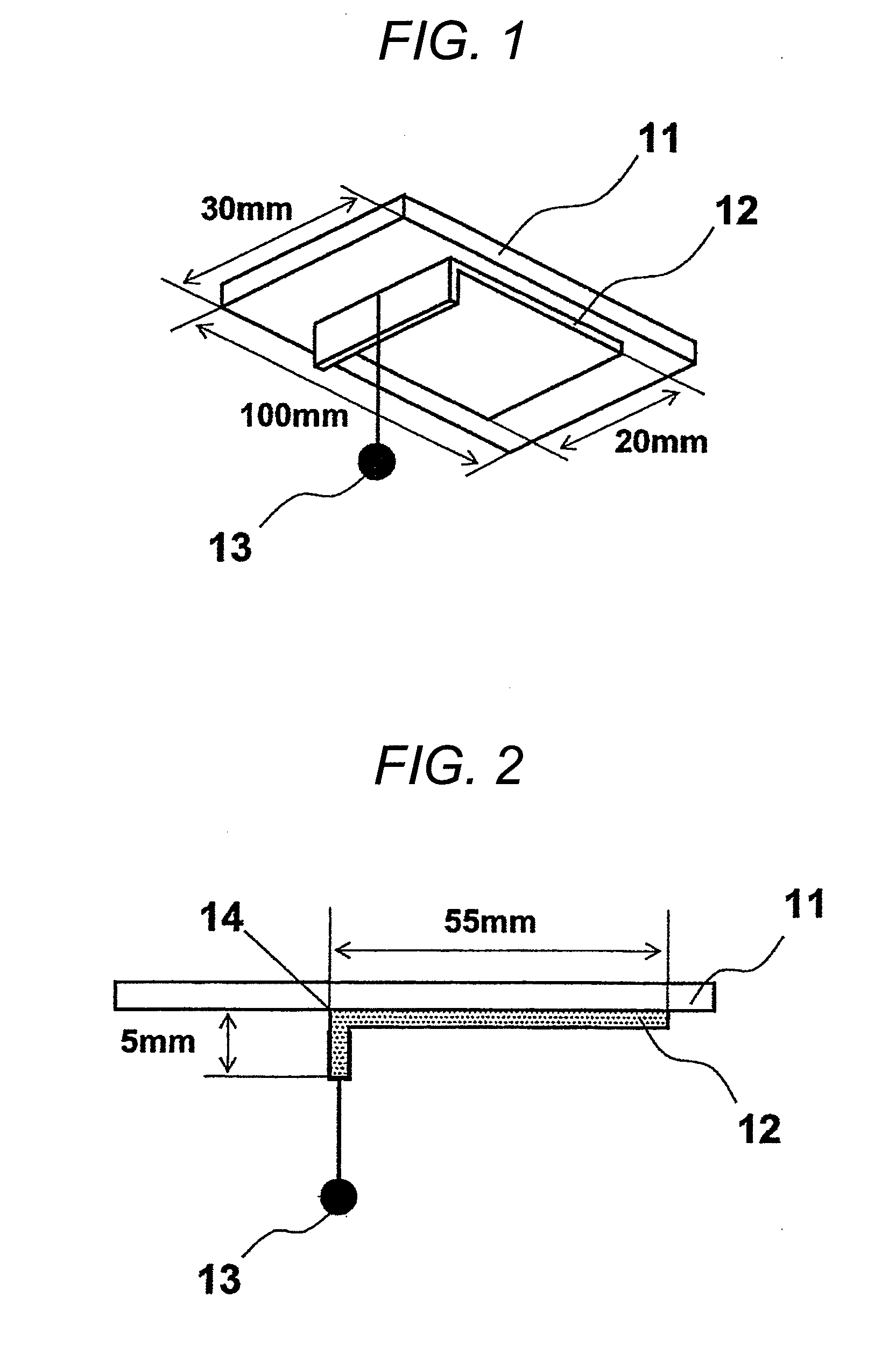

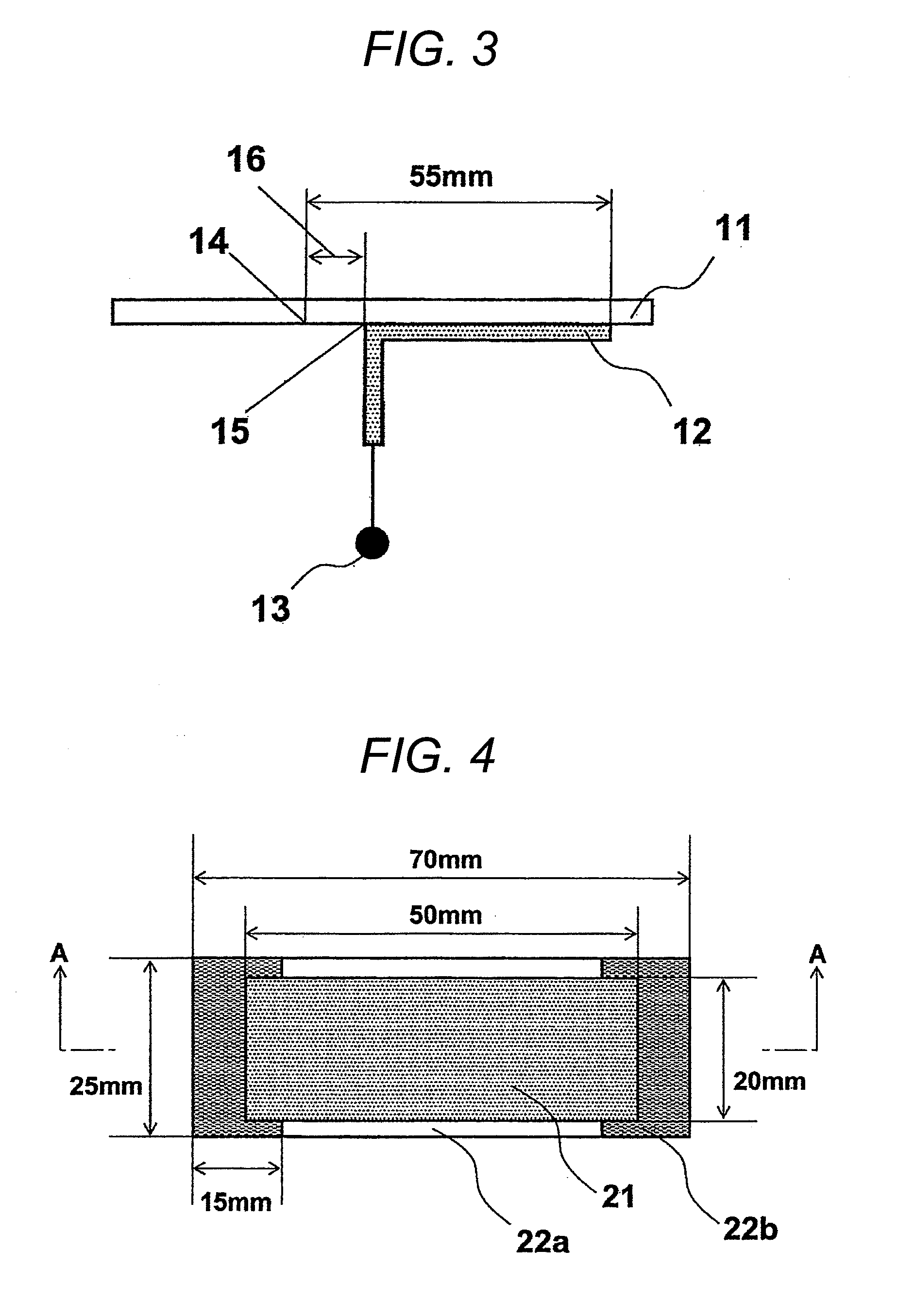

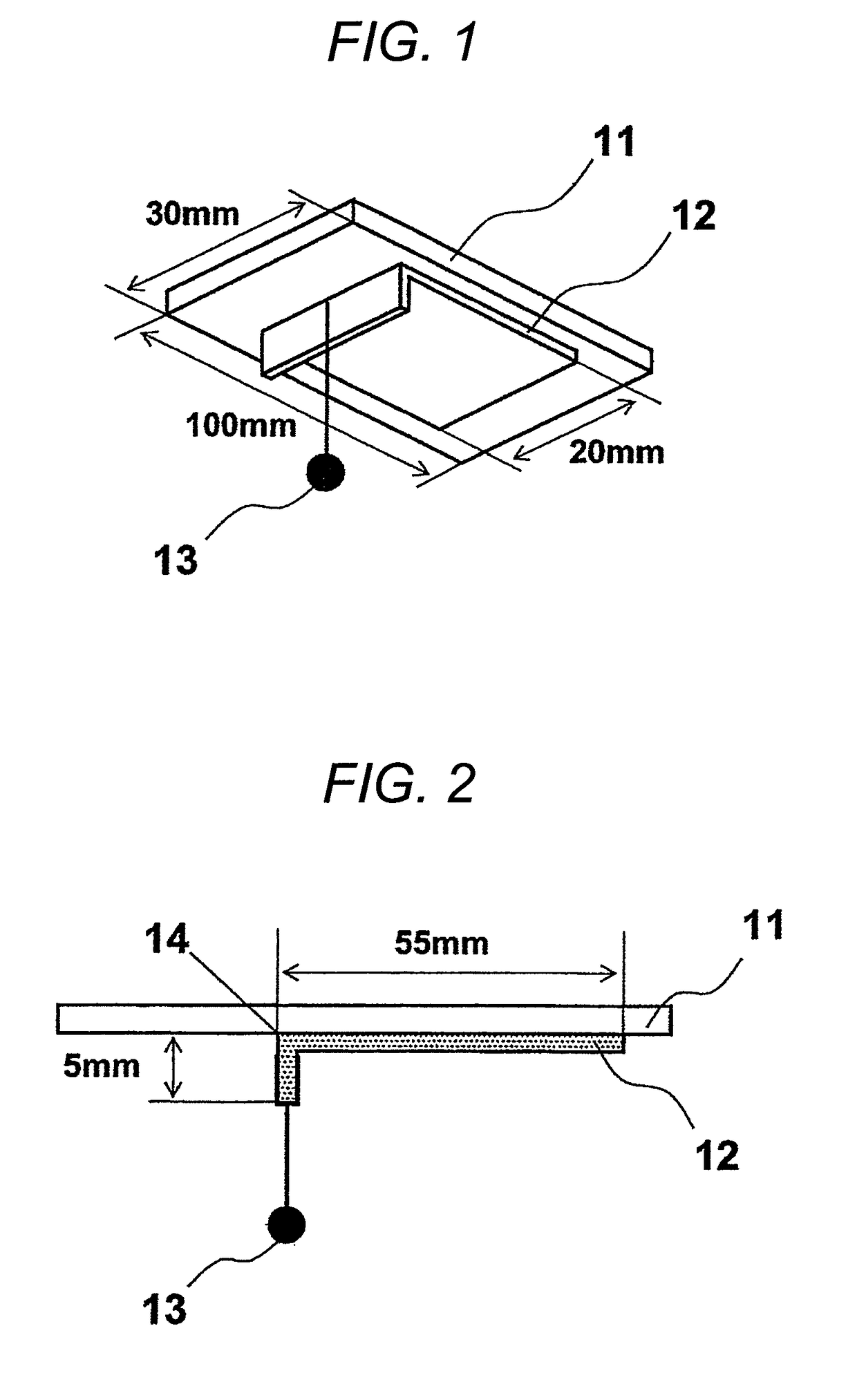

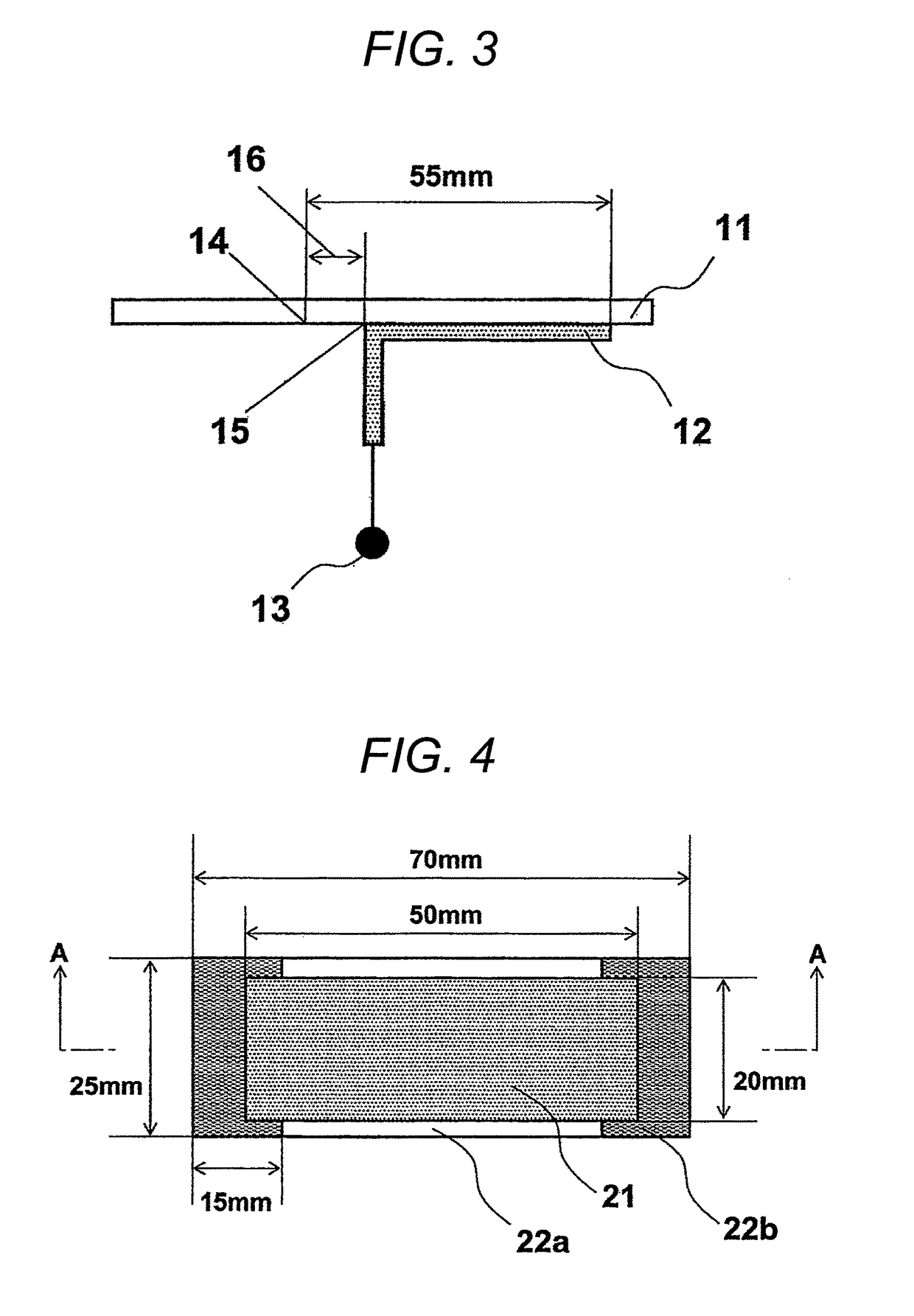

Provided are a method and system which use circulation-type hydrothermal reactions to process sludge by methane fermentation in an energy-efficient manner and stably over a long period of time. In this methane fermentation processing method, after the moisture content of the sludge (S) is adjusted to a prescribed level, the sludge (Sa) with the adjusted moisture content level is pumped into a circulation path (14a, 14b) connecting a hydrothermal reactor (11) and a gas-liquid separator (12) and is reduced in molecular weight by circulation for a prescribed period of time at a prescribed temperature and pressure, and the low molecular weight sludge (Sc) outputted from the circulation path (14a, 14b) is retained in a fermentation tank (20). The scale deposit state in the circulation path (14a, 14b) is continuously detected and the prescribed moisture ratio of the sludge (Sa) pumped into the circulation path (14a, 14b) is adjusted in response to the variation of the scale deposit state. Ideally, a flowmeter (31) and a flow rate control valve (32) are provided to control the circulation flow rate of the sludge (Sa) in the circulation path (14a, 14b) to the prescribed flow rate, the scale deposit state is detected from the opening degree of the flow rate control valve (32), or the scale deposit state is detected from the surface temperature of the circulation path (14a, 14b).

Owner:KAJIMA CORP +1

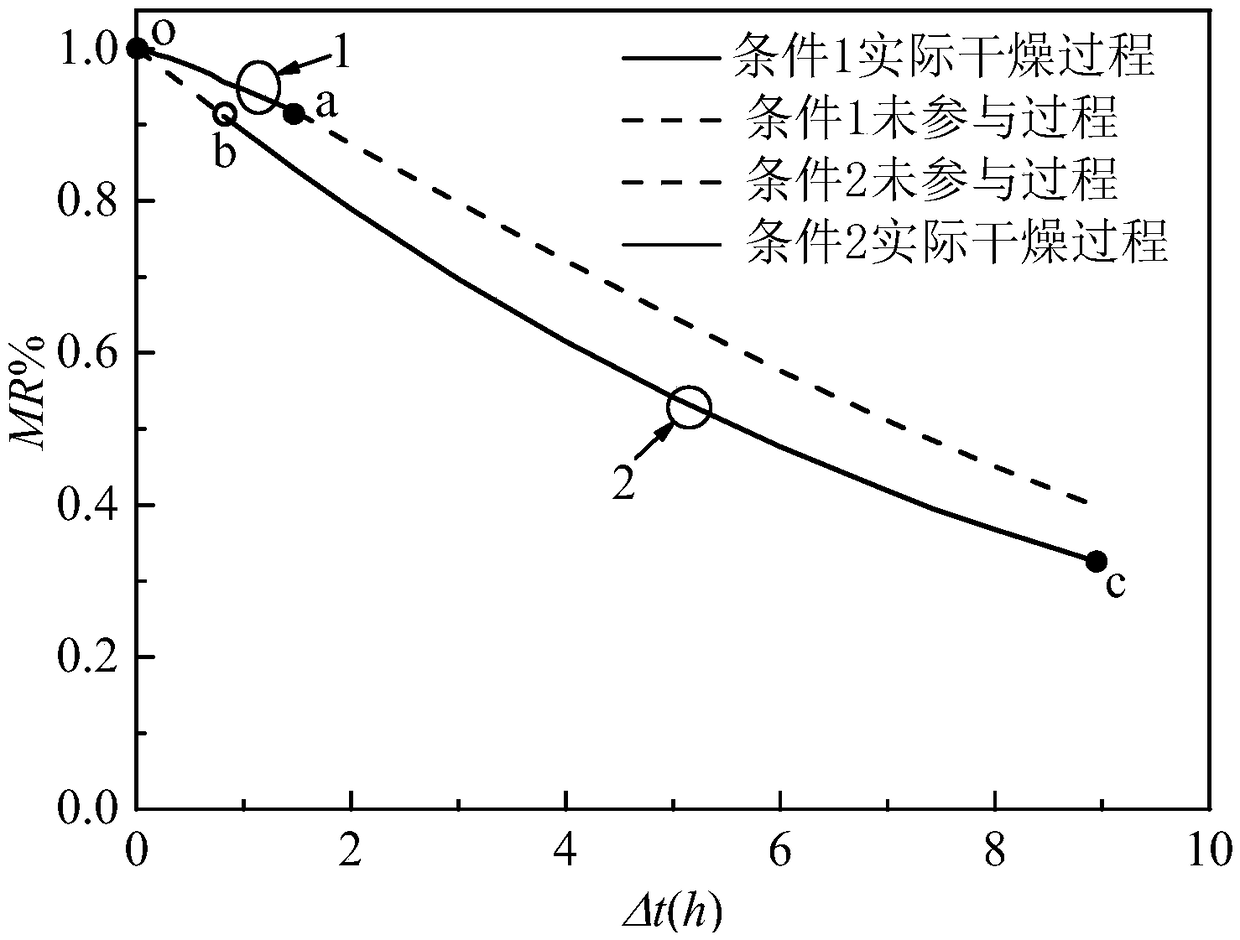

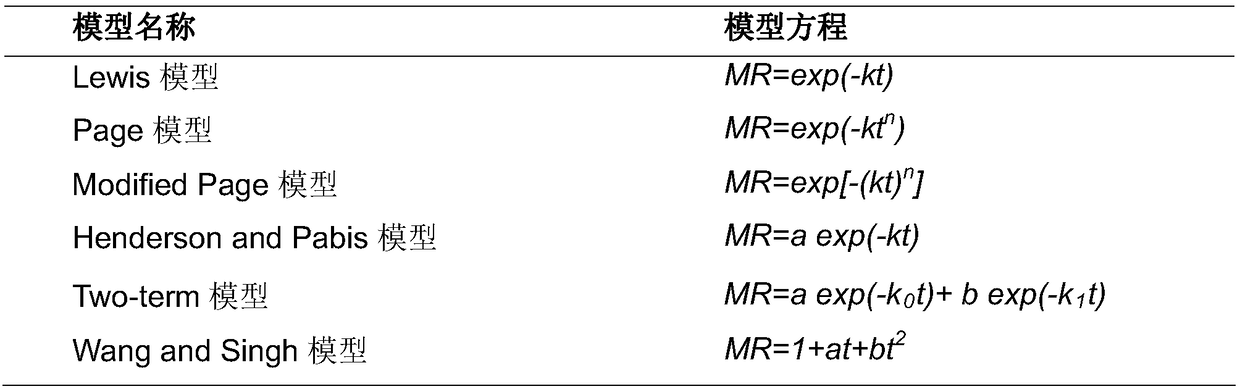

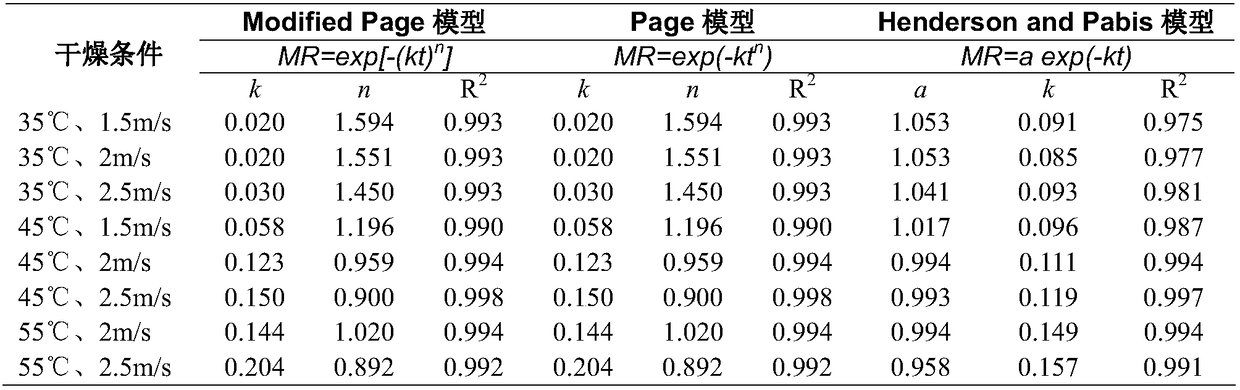

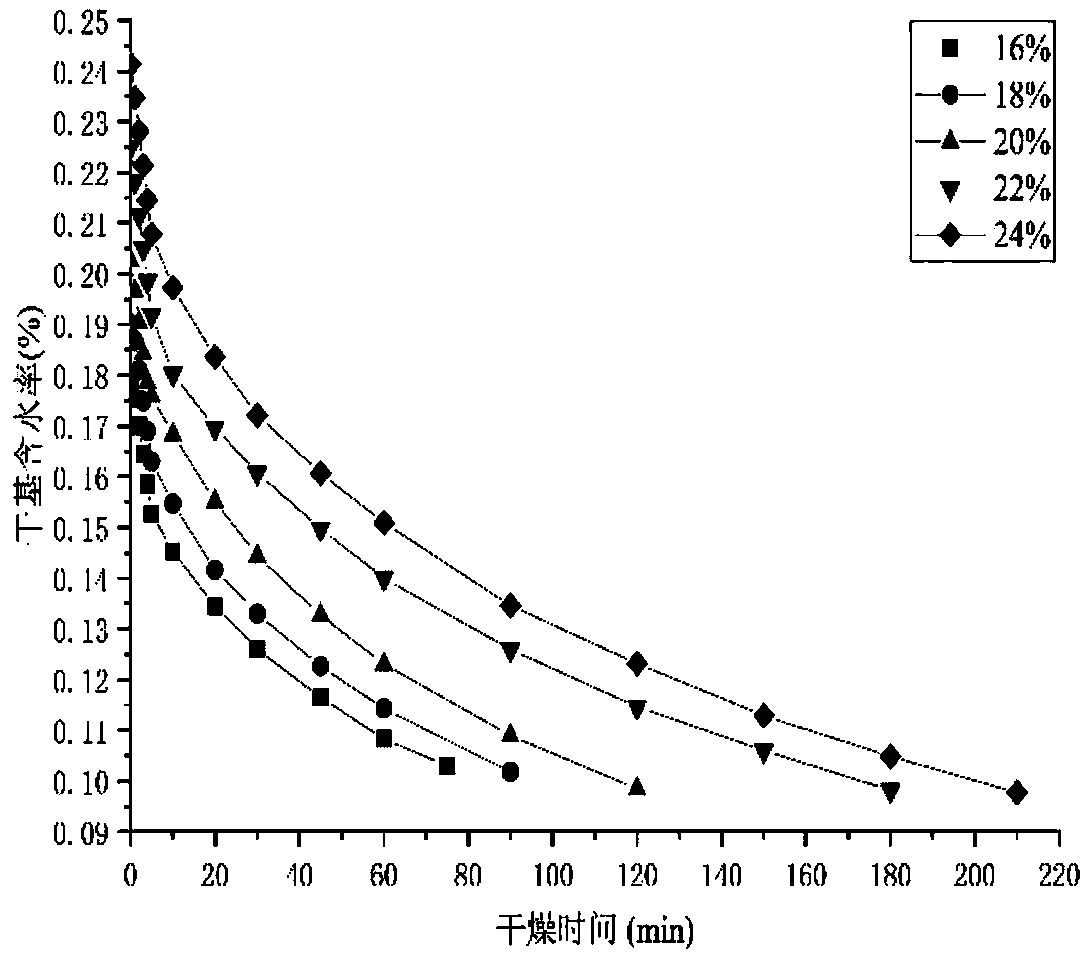

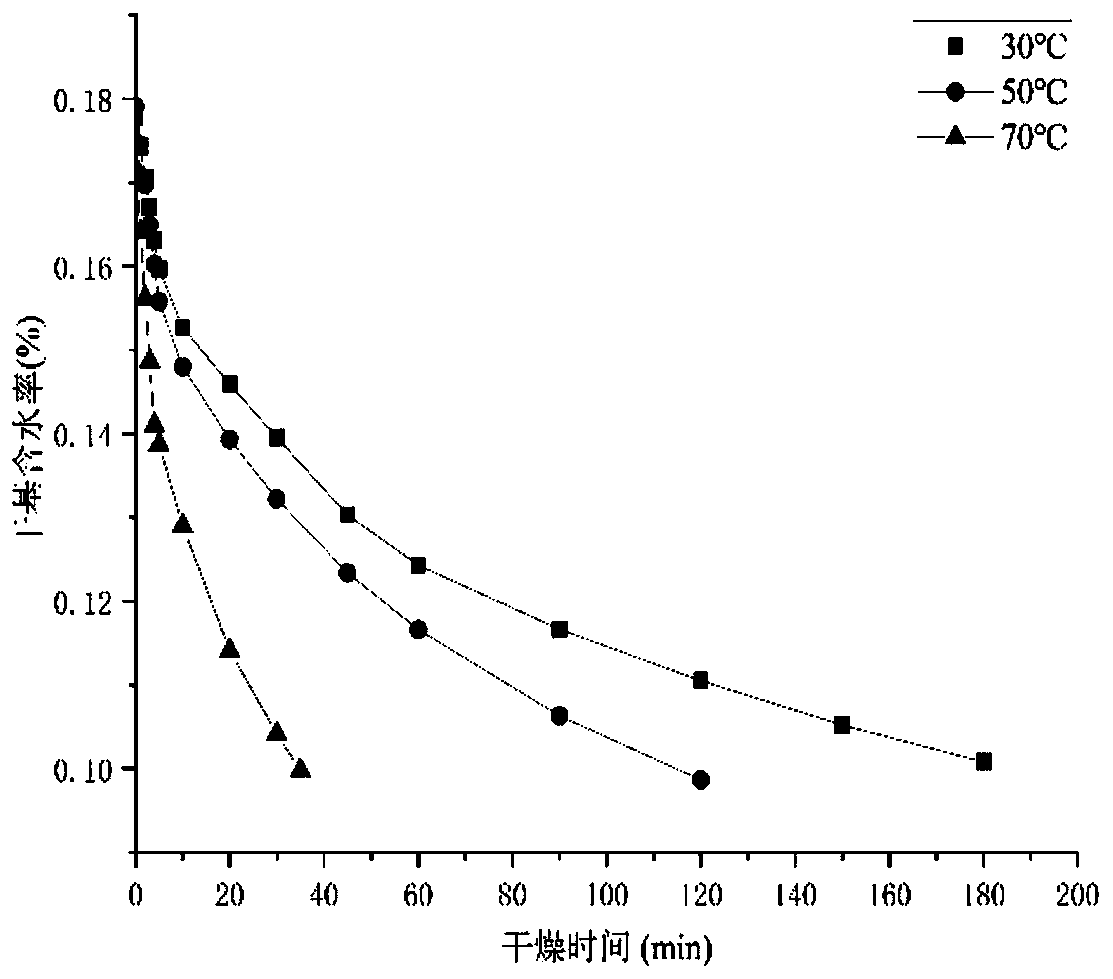

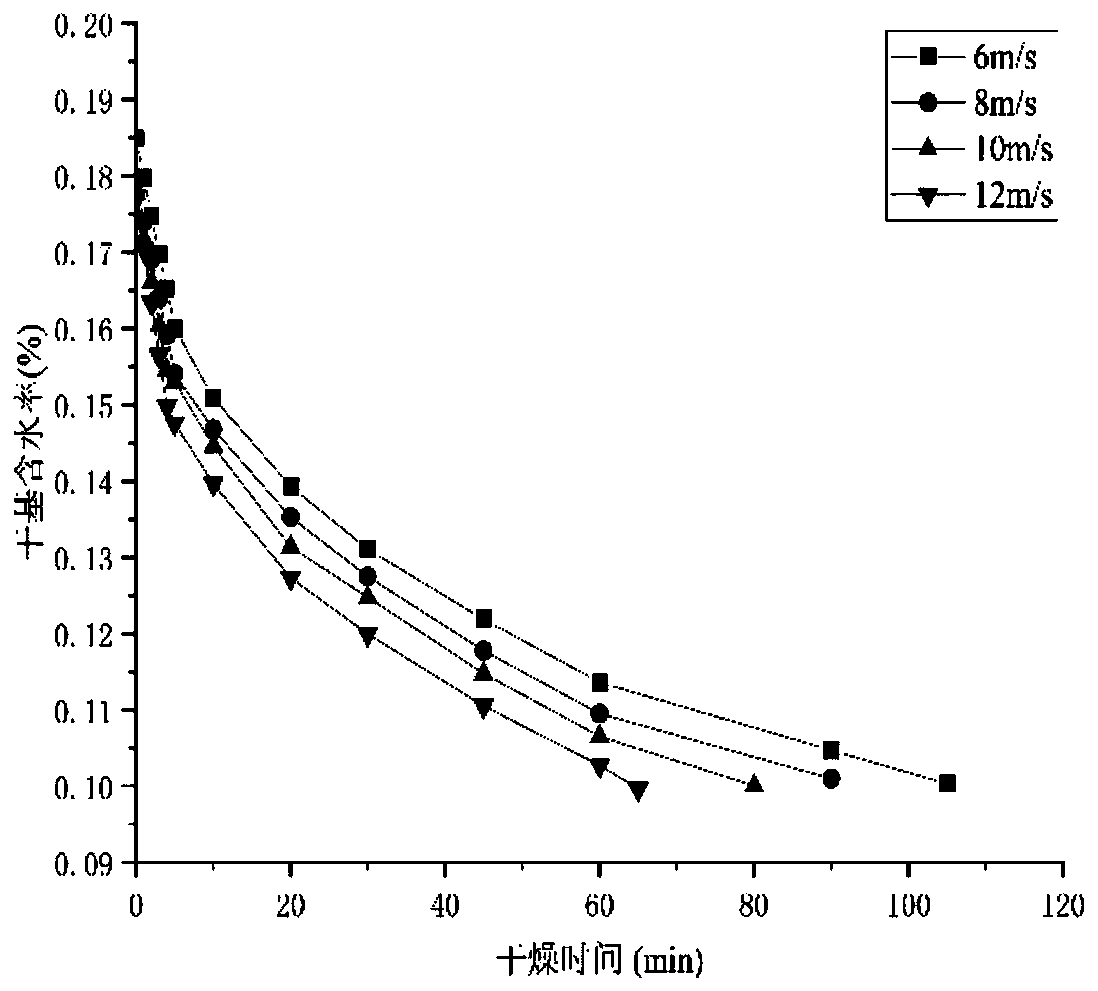

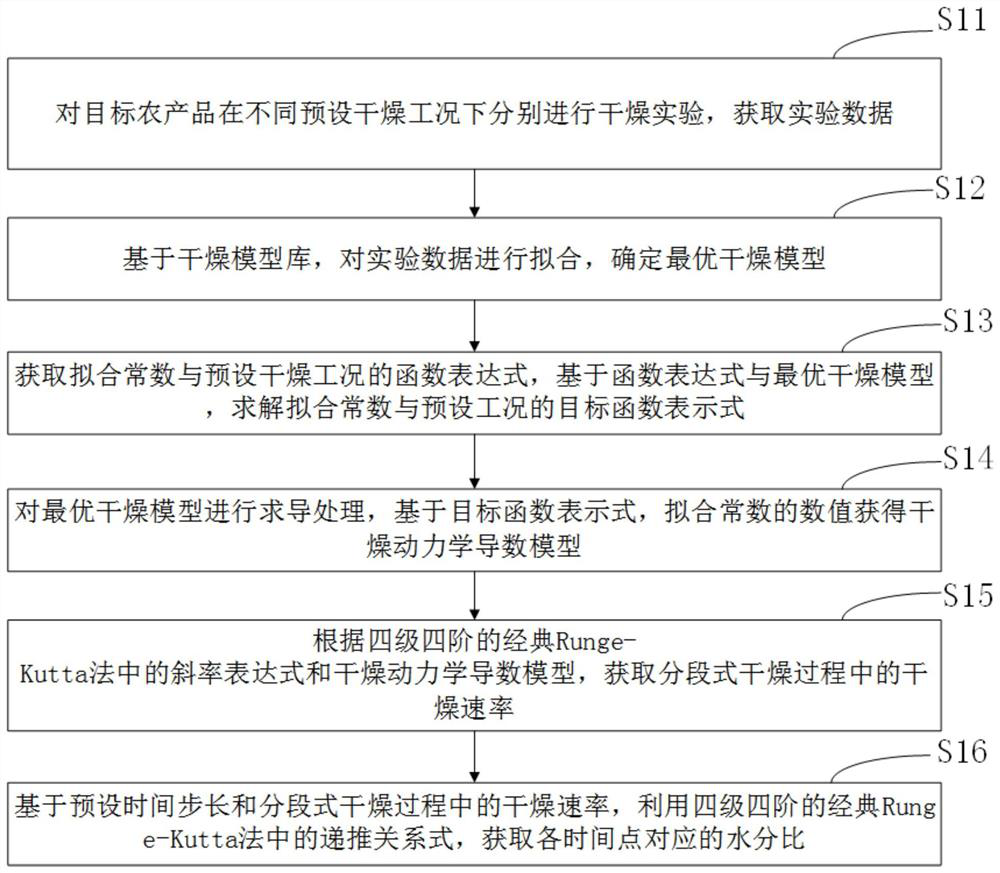

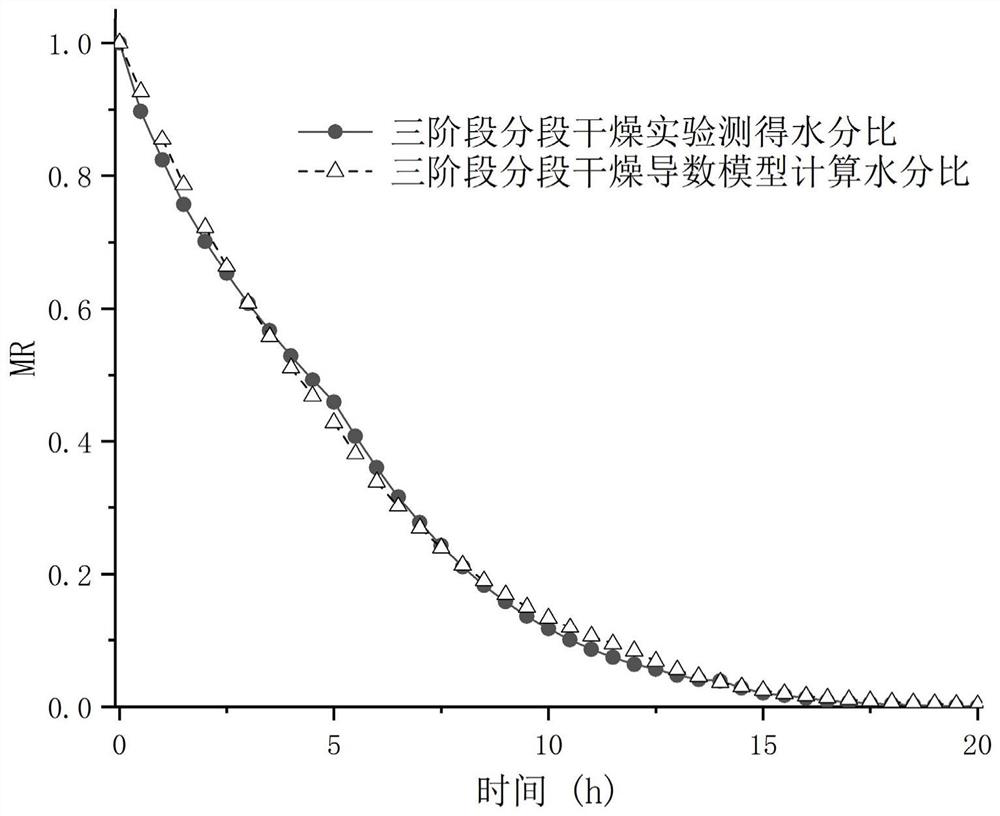

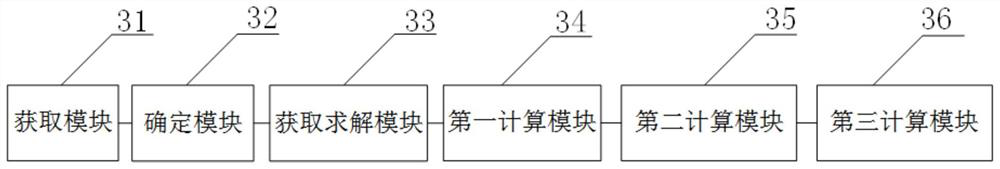

A moisture analysis method in segmented drying

PendingCN109271712AQuality improvementIncrease production capacityDesign optimisation/simulationSpecial data processing applicationsMoisture analysisProcess engineering

The invention discloses a moisture analysis method in segmented drying, which comprises the following steps of fitting and calculating the drying time and the moisture ratio of the material when the material to be dried is dried at constant temperature and constant speed under different drying conditions with a plurality of drying kinetic models, thereby determining an optimal drying kinetic model; the drying time and the moisture ratio of the material to be dried are calculated according to the optimum drying kinetic model. Fitting the different drying conditions with the drying constants inthe optimal drying kinetic model, thereby determining a functional equation between the drying conditions and the drying constants; The number of drying stages, drying time and drying conditions of each drying stage are selected, and then the optimum drying kinetic model and the drying constant equation are substituted to obtain the moisture change of the material to be dried in the segmented drying. The embodiment of the invention can meet the requirement of analysis and detection of complex moisture change in the segmented drying process, is favorable for designing, optimizing the segmenteddrying process, and improving the product quality and production energy efficiency of the segmented drying.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Optical pressure-sensitive adhesive sheet, optical film and display device

ActiveUS9695337B2Improve corrosion resistanceIncreased durabilitySynthetic resin layered productsAmide/imide polymer adhesivesConstant loadDynamic viscoelasticity

Owner:NITTO DENKO CORP

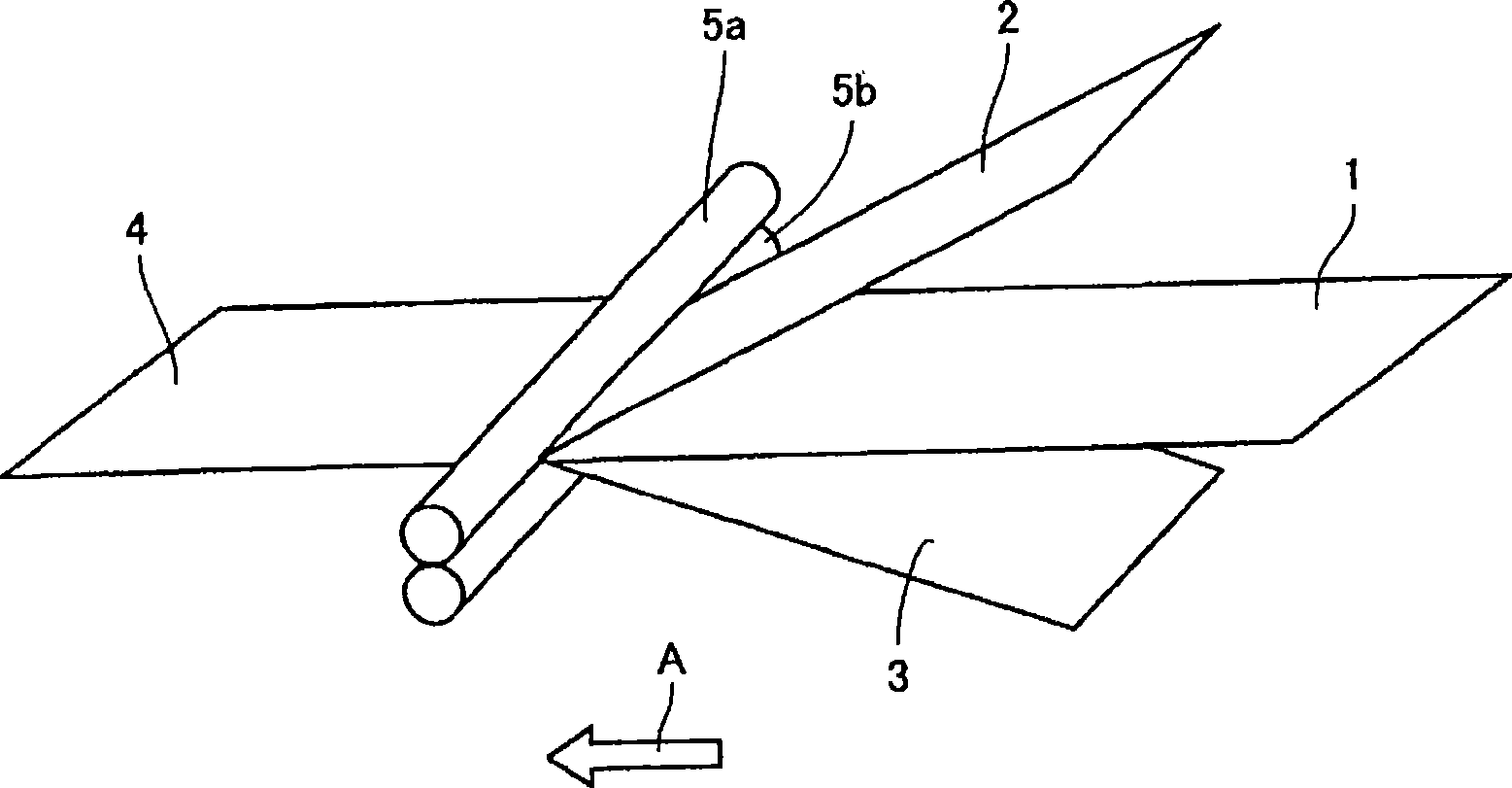

Method for producing veneer using wood strip integrated column

InactiveCN1803415AOvercome the practical difficulties of scarcityWood veneer joiningSEMI-CIRCLESprayer

The invention discloses a veneer making method of small integrated wood strip column, which comprises the following steps: cutting the manufacturing remains into small wood strip; drying the small wool strip with 12-15 percent moisture rate to apply glue or apply glue directly; calculating the quantity of small wool strip according to the bulk and weight of integrating column; arranging the small wool strip along longitude paralleling on the mould with semi-circle pipe upper-mold and lower-mold to assemble the model; moulding; selecting 1.0-2.5MPa compressor to do cold compression; solidifying and placing to make the small integrated wood strip column; doing rotary shaving through common rotary shaver when moisture ratio is more than 25 percent; doing rotary shaving through steam rotary shaver when moisture ratio is less than 20 percent; doing rotary shaving through flat sprayer; making the veneer. The invention utilizes waste material to make large board (veneer), which expands the source of veneer.

Owner:ZHEJIANG FORESTRY UNIVERSITY

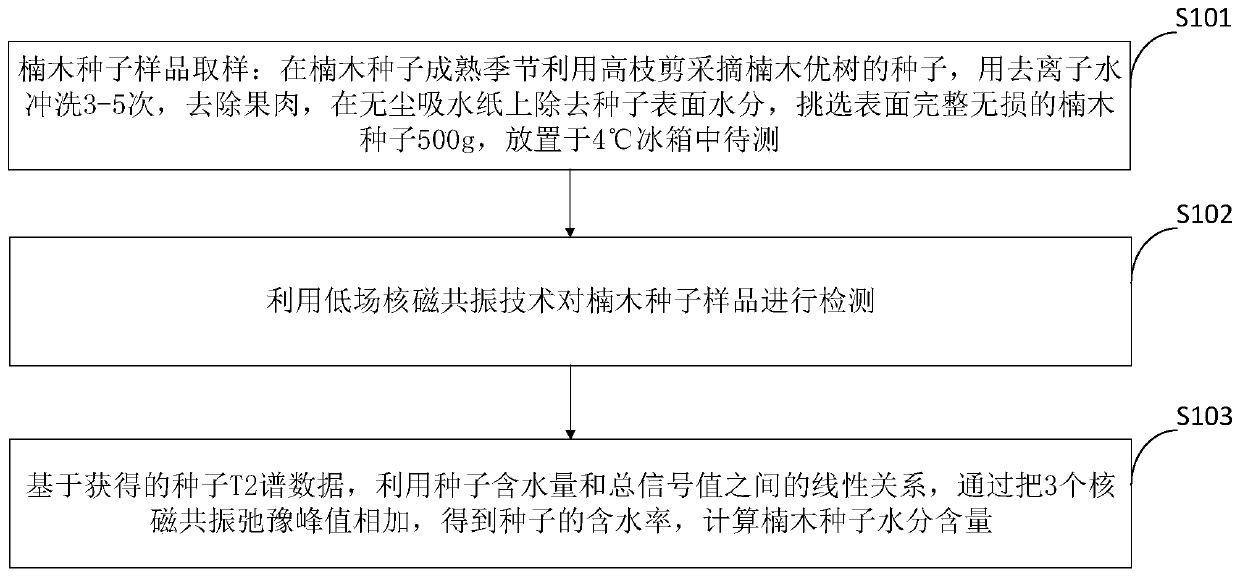

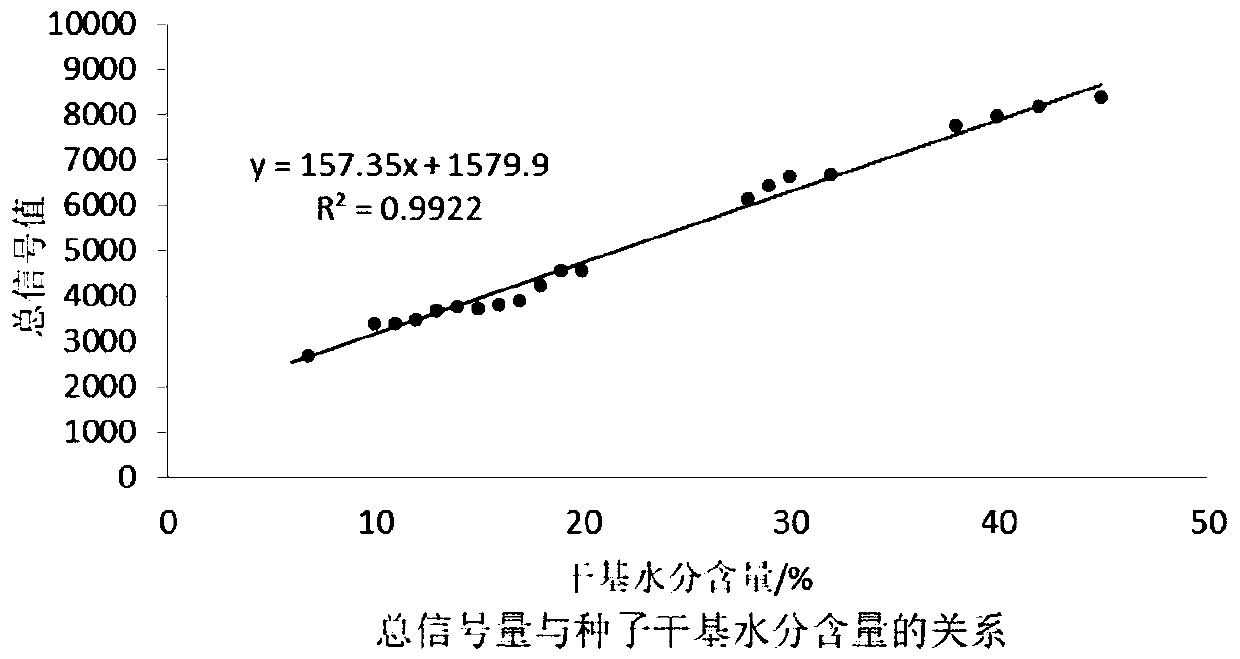

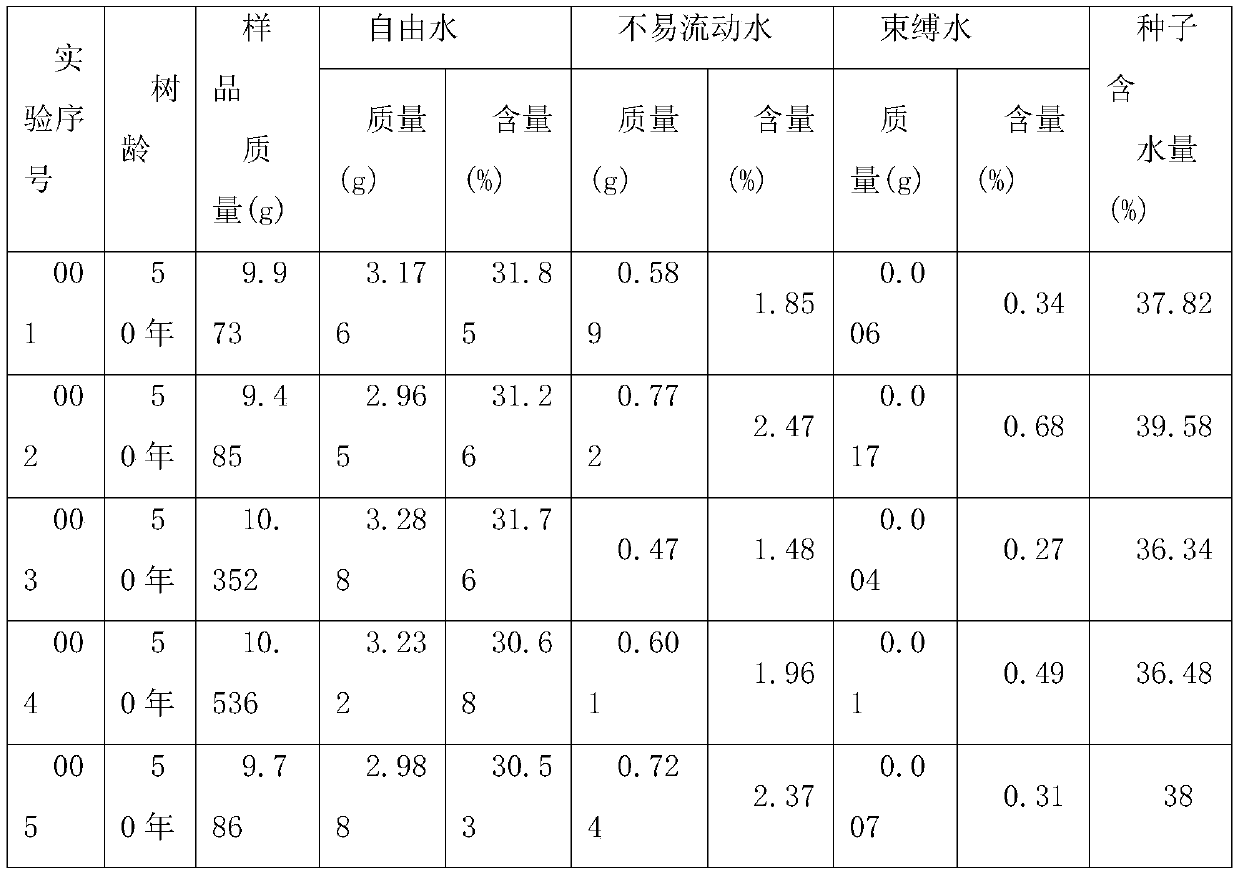

Method for measuring nanmu seed moisture content by using LF-NMR

InactiveCN110618159AScientificEasy to operateAnalysis using nuclear magnetic resonanceSurface moistureNMR - Nuclear magnetic resonance

The present invention belongs to the technical field of seed measurement, and discloses a method for measuring the nanmu seed moisture content by using LF-NMR (low-field nuclear magnetic resonance). The method comprises: sampling nanmu seed samples: during the maturity season of nanmu seeds, using a high-branch shear to pick the seeds of excellent nanmu trees, rinsing the seeds by using deionizedwater for 3-5 times, removing the flesh, removing the seed surface moisture on a dust-free absorbent paper, selecting 500g of nanmu seeds with a intact surface, and placing the nanmu seeds in a 4 DEGC refrigerator for testing; using the low-field nuclear magnetic resonance technology to test the nanmu seed samples; and based on the obtained T2 spectrum data of the seeds, using a linear relationship between the seed moisture content and a total signal value to obtain the seed moisture ratio by adding the three nuclear magnetic resonance relaxation peaks, and calculating the nanmu seed moisturecontent. The method provided by the present invention is highly scientific, and simple and easy to operate, is not affected by human factors and environmental factors, and is accurate and objective in result; and compared with the traditional drying methods, time is more saved and the measurement result is more accurate by using the method provided by the present invention.

Owner:HUBEI UNIV FOR NATITIES

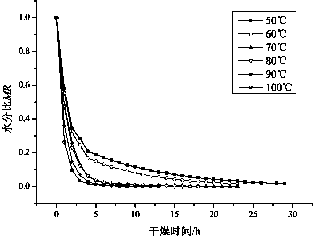

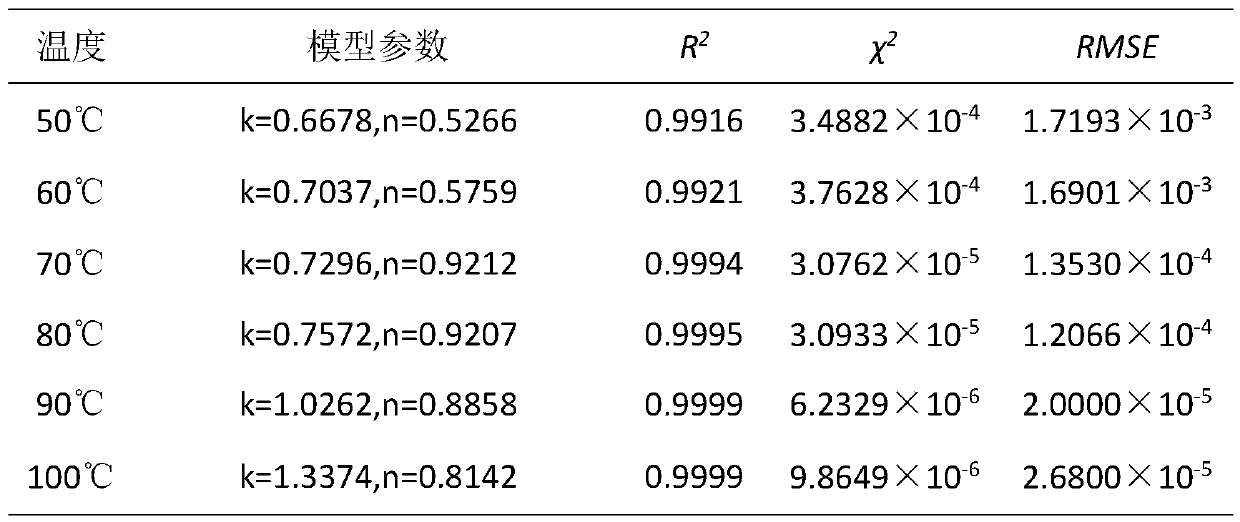

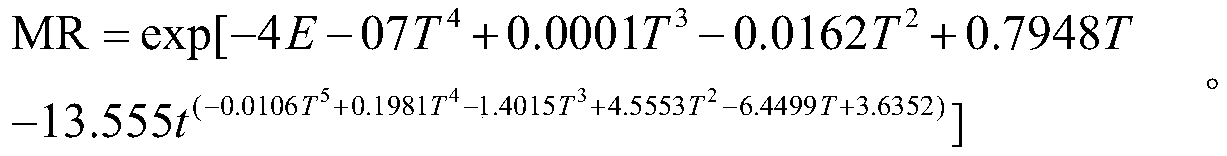

Method for predicting hippocampus hot air drying process by utilizing Page mathematical model

PendingCN110472330AAccurate descriptionAccurate predictionSpecial data processing applicationsMathematical modelCurve fitting

The invention relates to a method for predicting a hippocampus hot air drying process by using a Page mathematical model, which comprises the following steps: S1, randomly selecting a plurality of different hot air drying temperatures to dry hippocampus to obtain drying curves of moisture ratios and drying time at different temperatures; S2, providing a Page drying model, and performing nonlinearregression analysis on the drying curve of the moisture ratio and the drying time by using an Origin data processing tool; S3, obtaining expressions of the parameters k and n about the temperature (T)through curve fitting; and S4, substituting the parameters k and n obtained in the step S3 into a Page drying model to obtain a hippocampus drying kinetic model, and giving a change relationship of the water ratio along with the temperature T unit DEG C and the time t unit h in the hippocampus hot air drying process by the model to predict the water ratio of the dried hippocampus at different temperatures. The drying model can accurately describe and predict the hippocampus drying process, the drying process is accurately controlled, and an important basis is provided for structural design and parameter optimization of drying equipment.

Owner:FISHERIES RES INST OF FUJIAN

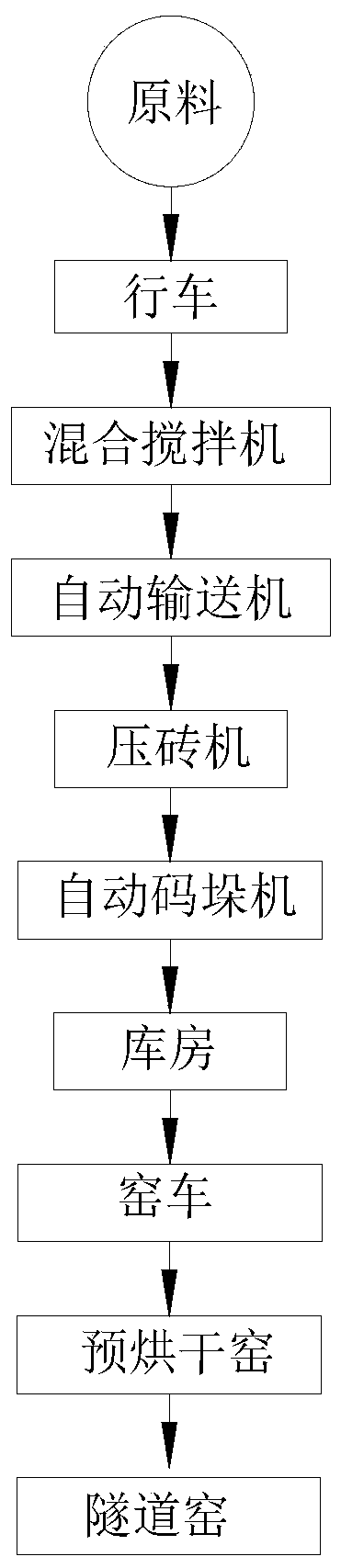

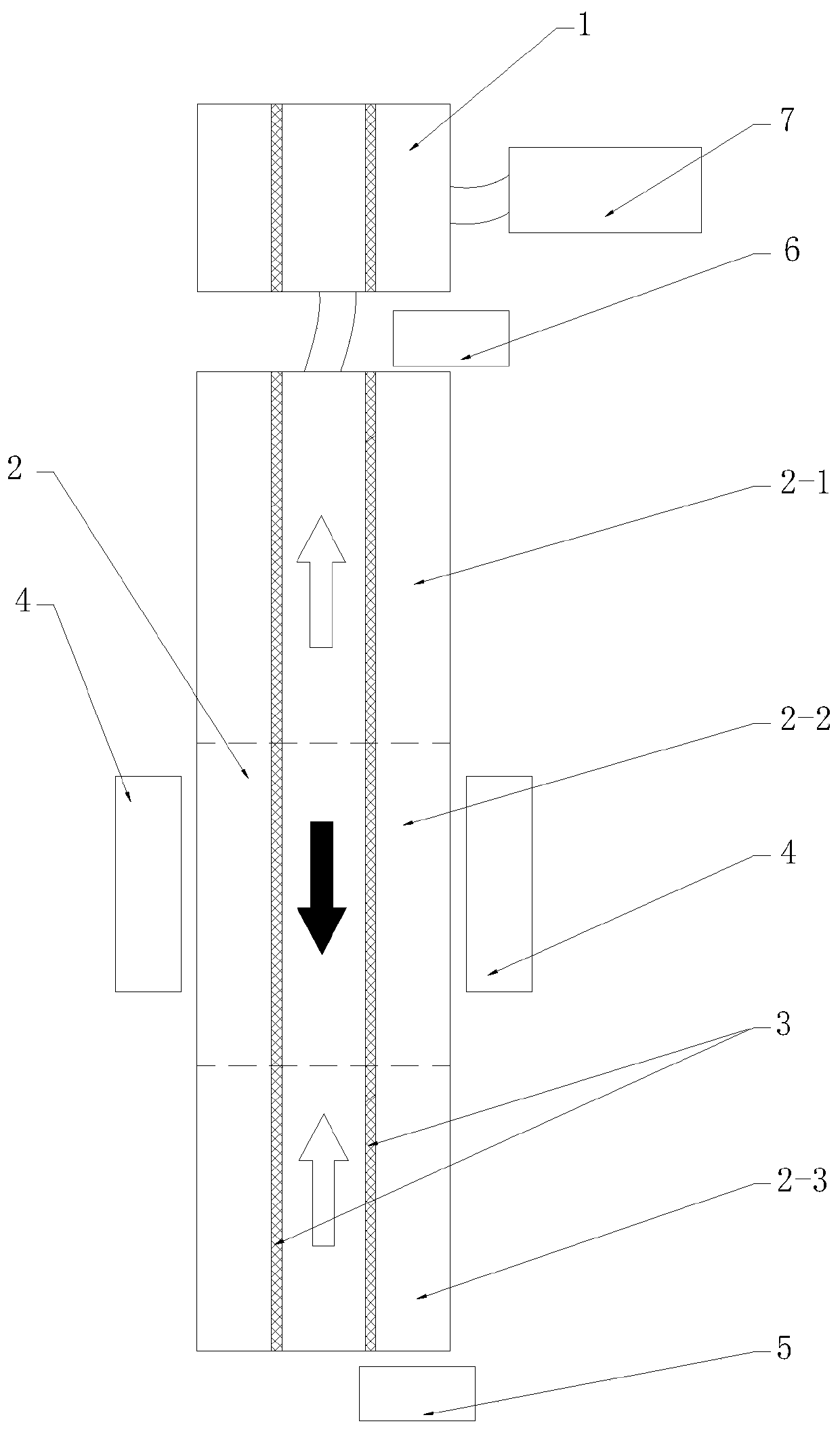

Strontium carbonate forming and calcining process for preparing strontium oxide

InactiveCN110482583AAvoid Burnout ProblemsReduce labor intensityCalcium/strontium/barium oxides/hydroxidesStrontium carbonateBrick

The invention relates to a strontium carbonate forming and calcining process for preparing strontium oxide. Strontium carbonate powder or strontium carbonate slurry is adopted as a raw material; wateror strontium carbonate powder is added into the raw material to adjust the moisture ratio; stirring and mixing are conducted to form a brick-shape product; the brick-shape product is conveyed to a storehouse to be dried in the shade, loaded into a kiln car, conveyed to a pre-drying kiln to be dried and conveyed to a tunnel kiln to be calcined to obtain the strontium oxide. According to the process, a brick-making forming process is adopted, the strontium carbonate powder and the strontium carbonate slurry can be adopted as raw materials, the purchasing cost is obviously reduced, the problem that dust is pumped out and wasted in the calcining process of the strontium carbonate powder is solved, and the cost is further saved. The problem of powder calcining and sintering furnaces is avoided, long-time continuous production can be achieved, and the yield is increased. The labor intensity of workers is reduced and the production efficiency is improved. A tunnel kiln calcining process is adopted, energy is fully utilized, calcining time is shortened, high-temperature calcining ensures the decomposition rate, and the strontium oxide content in products is increased.

Owner:重庆庆龙新材料科技有限公司

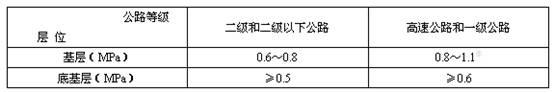

Highroad pavement base and roadbed material containing slag fly ash of coal-fired power plant and stabilized by levigated lime

The invention relates to a highroad pavement base and roadbed material, in particular to a highroad pavement base and roadbed material containing slag fly ash of a coal-fired power plant and stabilized by levigated lime, which is prepared, in weight percentage, by mixing 100% of slag fly ash of the coal-fired power plant and 1%-10% of levigated lime with water, and the moisture ratio of the highroad pavement base and roadbed material is 10%-30%. The highroad pavement base and roadbed material as a novel inorganic material is higher in strength and lower in cost, and castaway slag ash of a domestic refuse incineration plant is reasonably applied.

Owner:上海寰保渣业处置有限公司

Combined extrusion coupling homogenization dehydration method

PendingCN109783992AHomogenization and dehydrationSpecial data processing applicationsDynamic modelsEngineering

The invention provides a combined extrusion coupling homogenization dehydration method, and belongs to the technical field of drying methods. The method comprises the following steps: grinding grains,sieving, and drying to obtain grain powder; Carrying out twin-screw extrusion treatment on the grain powder; establishment of dynamic model, Starting fluidized bed device, adjusting device parameters, after the set parameter conditions of the fluidized bed are stable; the screen is placed in a fluidized bed to be fixed, the materials are flatly laid in the screen to be dried, the inlet air temperature, the drying air speed, the water adding amount and the drying time are substituted into a kinetic model formula, the moisture ratio MR is obtained, the dry basis moisture content is determined,the drying time of the materials in the fluidized bed is determined according to the national standard requirement, and material homogenizing dehydration is achieved; and putting the dried materials on an oven conveyor belt, and performing secondary puffing treatment to obtain the final product. By establishing the dynamic model, the drying rate and the material moisture content of the fluidized bed under different process conditions at different moments can be predicted to accurately control the fluidized bed, so that the purpose of homogenizing dehydration is achieved.

Owner:JILIN AGRICULTURAL UNIV

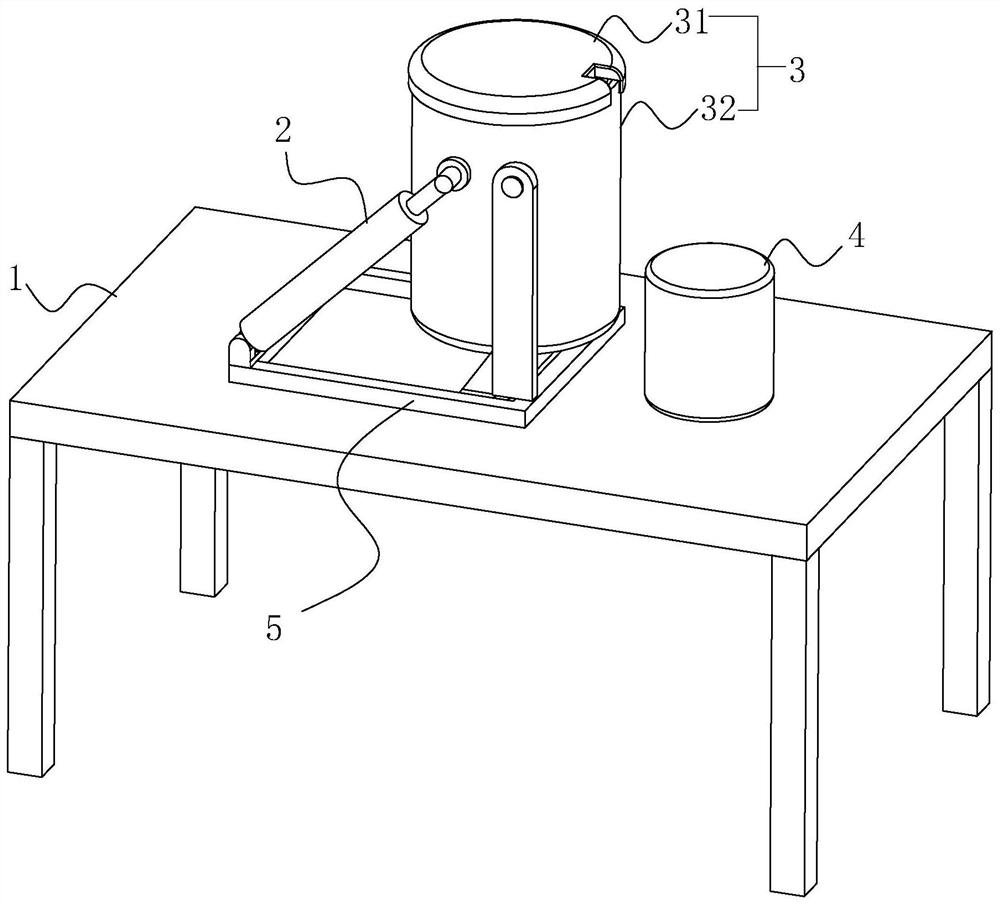

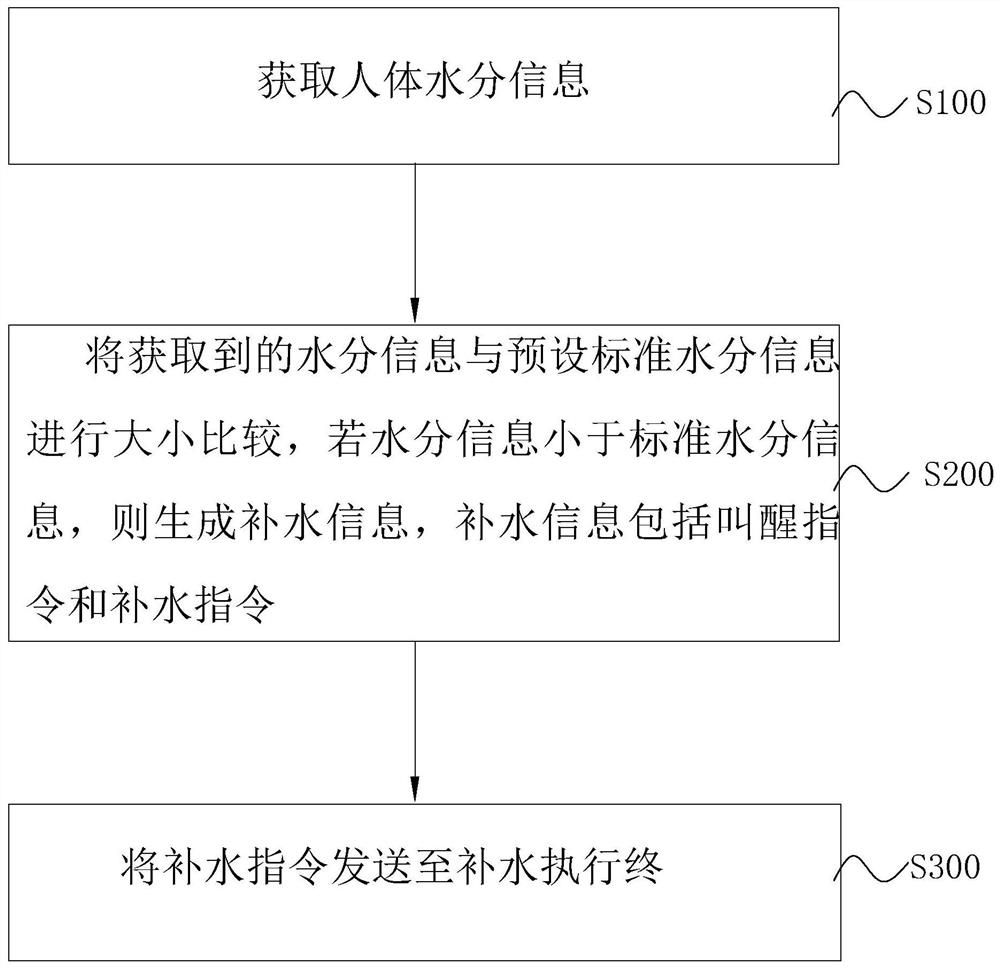

Intelligent home control system and method and storage medium

PendingCN111796528AIncrease moisture contentHydration achievedMeasurement devicesComputer controlHuman bodyControl system

The invention relates to an intelligent home control system and method, and a storage medium. The method comprises the steps of obtaining target moisture information; comparing the obtained moisture information with preset standard moisture information, if the moisture information is smaller than the standard moisture information, generating water supplementing information, and the water supplementing information comprising a wake-up instruction and a water supplementing instruction; and sending the water supplementing instruction to a water supplementing execution terminal. Whether the humanbody needs to be replenished with water or not at the moment is judged by detecting the target moisture information of a human body in sleep, so that when the human body needs to be replenished with water, a water supplementing terminal is controlled to replenish water to the user by sending the water supplementing instruction to the water supplementing execution terminal, the purpose of supplementing water is achieved, and the moisture ratio of the human body is in a better state.

Owner:深圳市幸福人居建筑科技有限公司

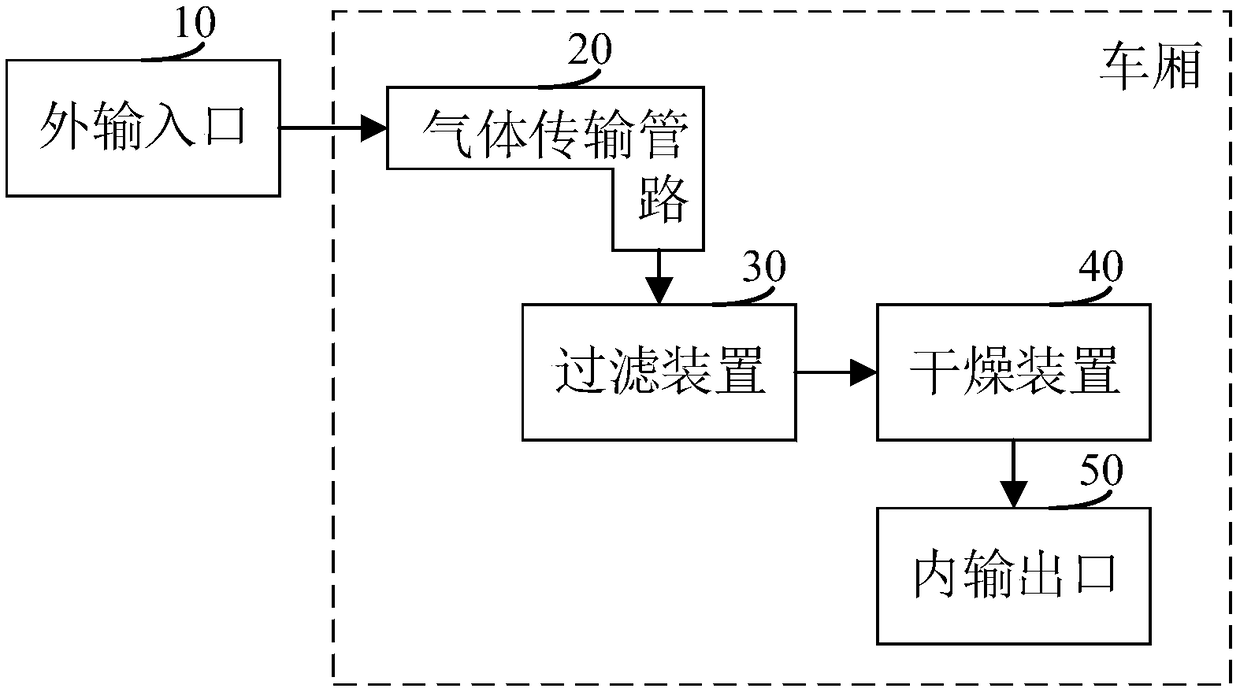

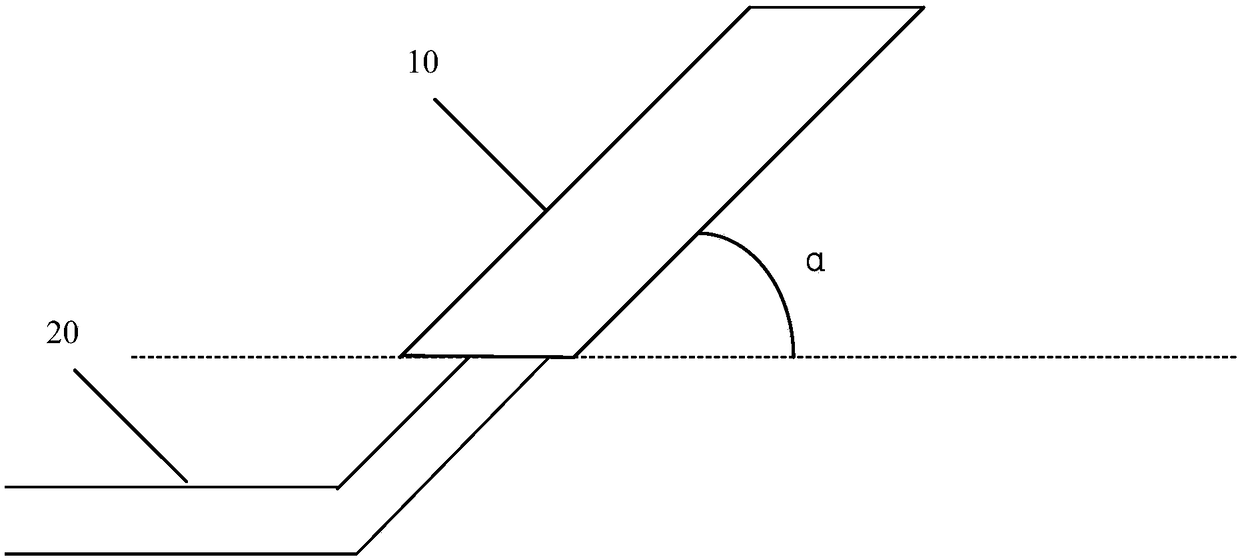

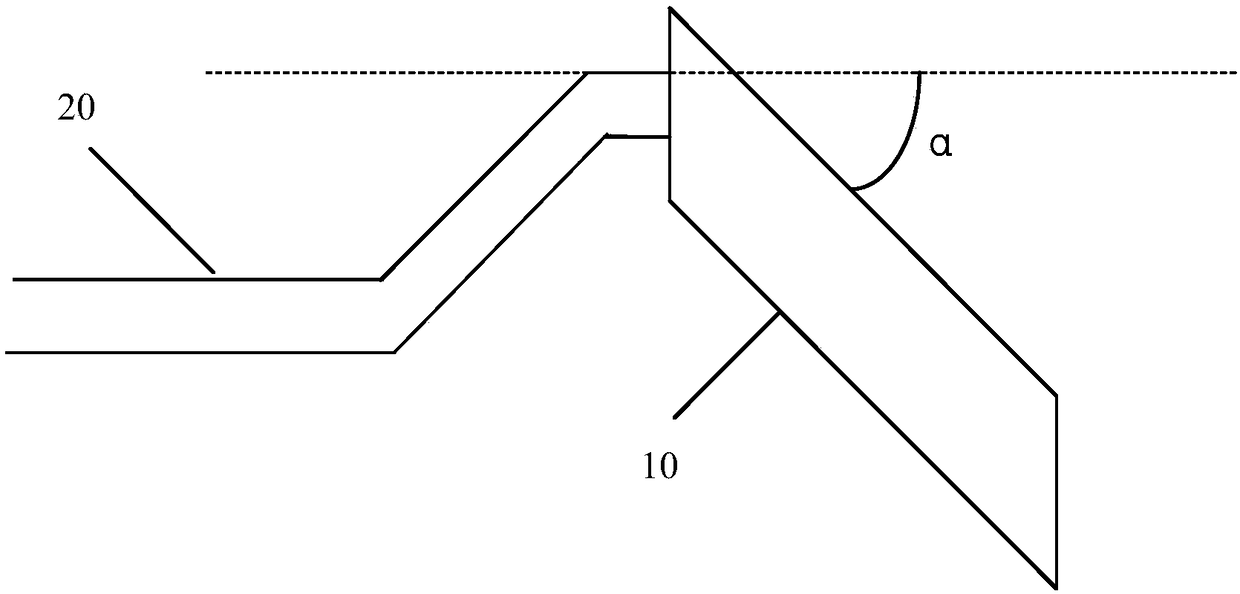

Train compressed gas treatment equipment and method

ActiveCN109316906AExtended service lifeReduce testing costsGas treatmentDispersed particle filtrationProcess engineeringEngineering

The invention discloses train compressed gas treatment equipment. The train compressed gas treatment equipment comprises an external input opening, a transportation pipeline, a filtering device, a drying device and an internal output opening, wherein the external input opening is used for receiving compressed gas input from the exterior; the transportation pipeline is connected with the external input opening and is used for transporting the compressed gas; the filtering device is connected with an output end of the gas transportation pipeline and is used for filtering impurities in the compressed gas; the drying device is connected with the filtering device and is used for reducing the water content; the internal output opening is connected with an output end of the drying device and is used for outputting the compressed gas with a moisture ratio lower than a pre-set ratio. According to the train compressed gas treatment equipment disclosed by the invention, the input compressed gas can be treated by sufficiently utilizing vehicle-mounted equipment and compressed gas treatment equipment does not need to be additionally arranged at the exterior, so that the testing, operation and maintenance cost is reduced and the service life of each related element is prolonged. The invention further discloses a treatment method applied to the train compressed gas treatment equipment and thetreatment method has the same beneficial effects.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

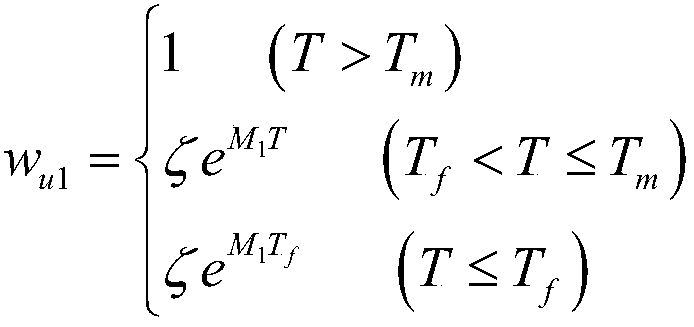

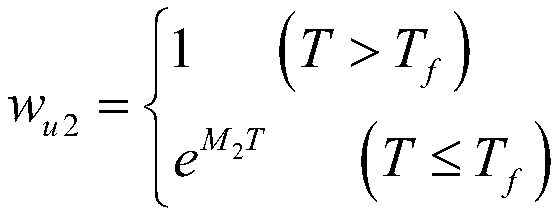

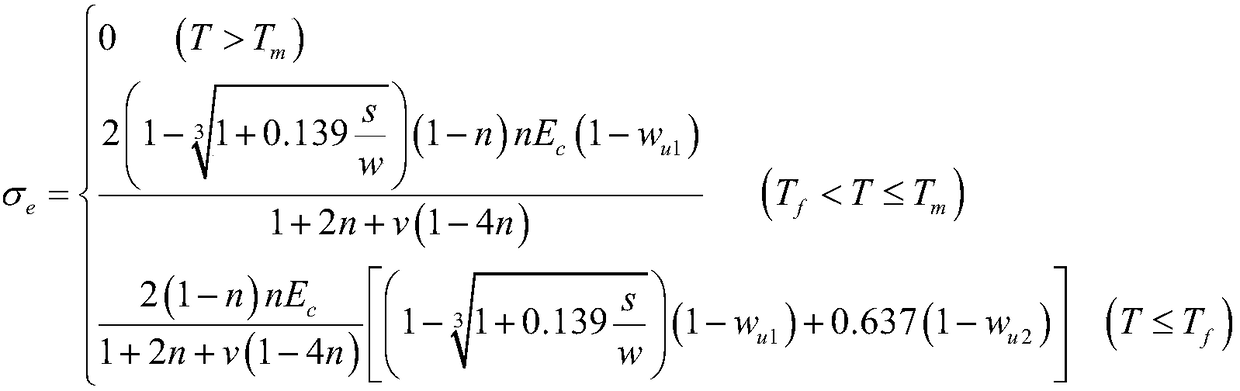

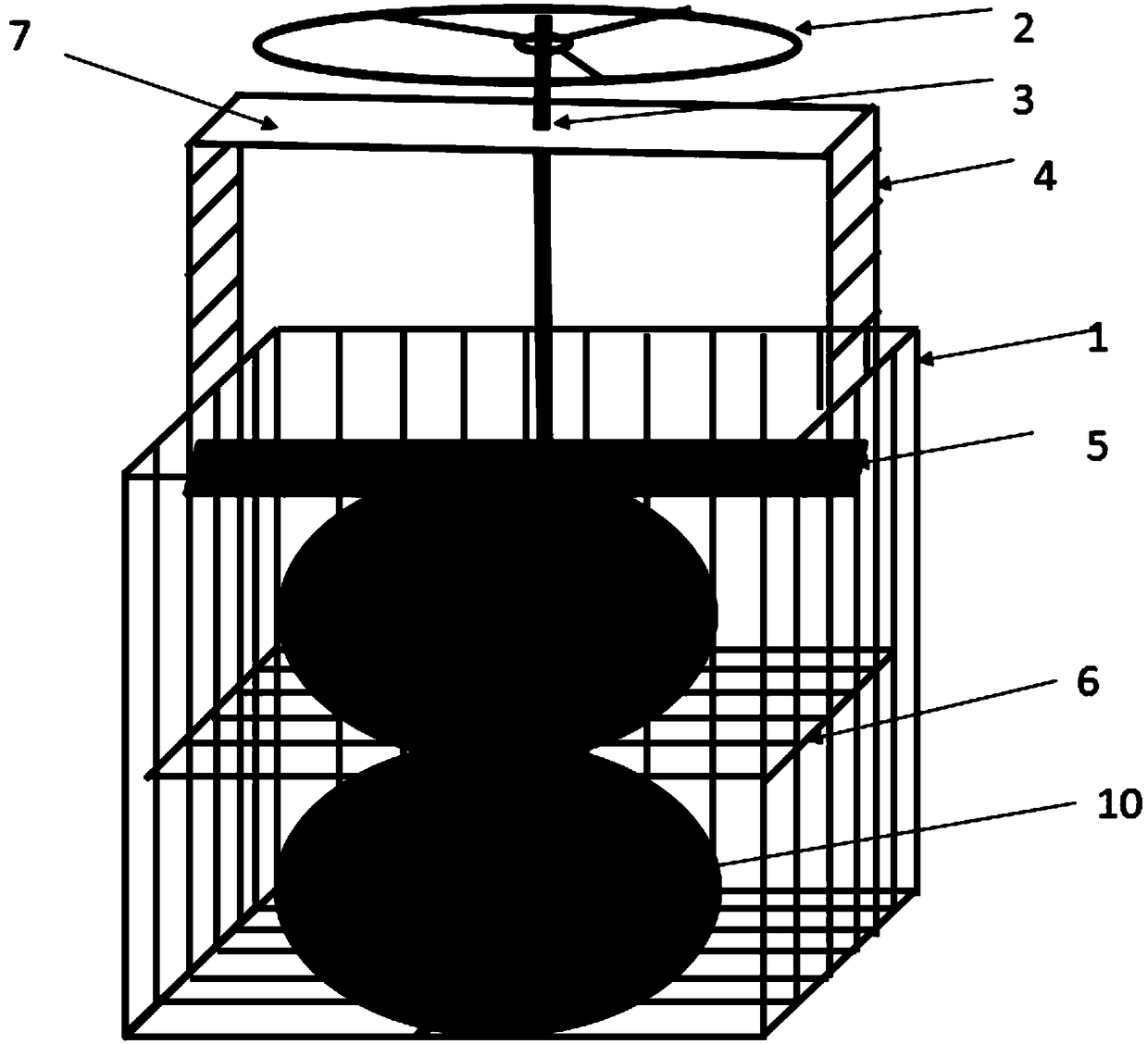

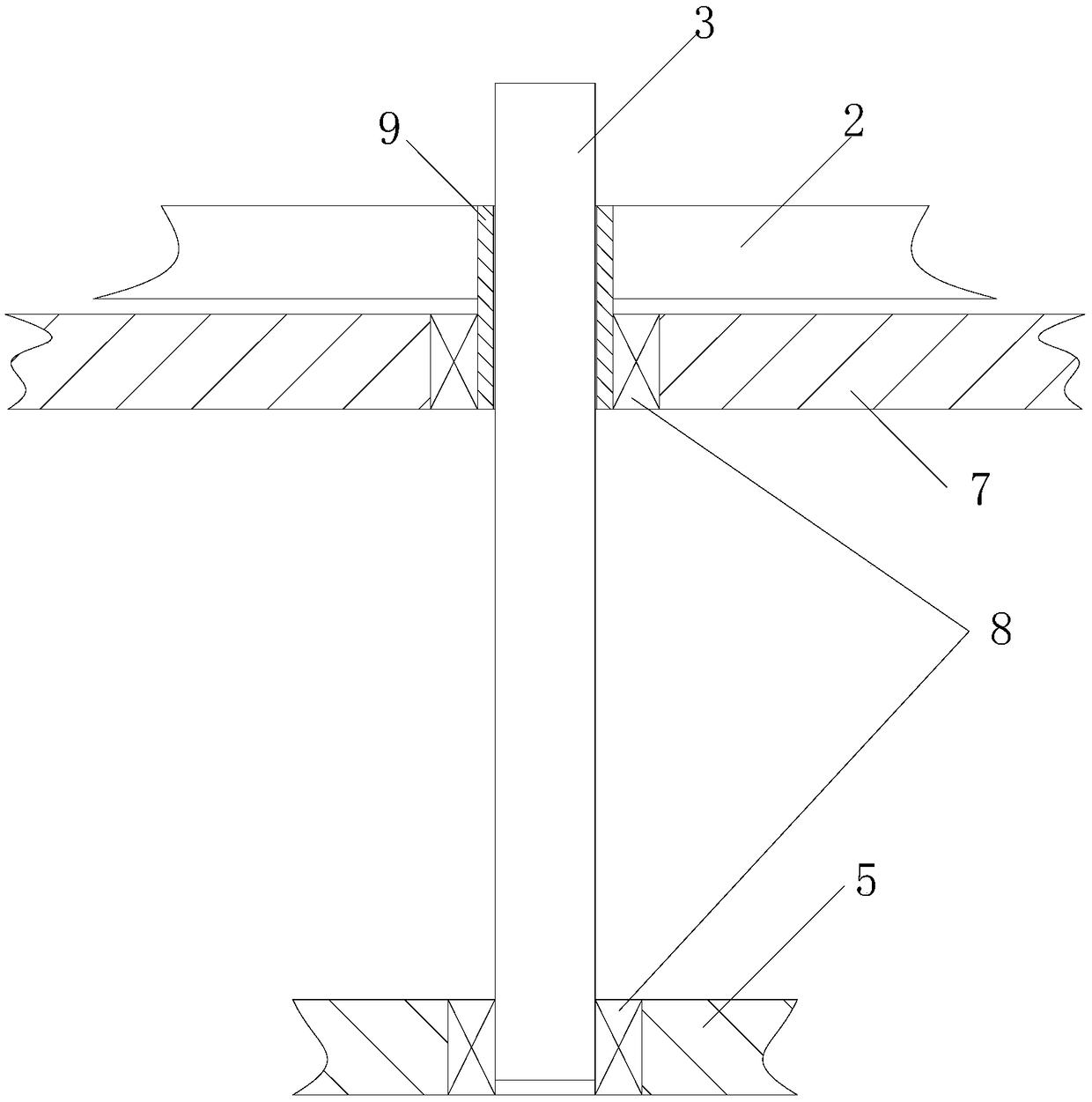

High-salinity salinized soil salinity-frost heaving force determining method

ActiveCN109490353AConvenient surveyOvercoming the disadvantages of determining the salt-frost heaving force of high-salinity saline soil by indoor testMaterial thermal analysisApparatus for force/torque/work measurementPorosityIce water

Disclosed is a high-salinity salinized soil salinity-frost heaving force determining method. The high-salinity salinized soil salinity-frost heaving force determining method achieves determination ofthe salinity-frost heaving force of the high-salinity salinized soil in salinized soil areas through scientific and reasonable investigation to meet the demands of practical engineering. The high-salinity salinized soil salinity-frost heaving force determining method comprises the following steps of, through field sampling and indoor geo-technical testing, determining the natural moisture contentw, the porosity n, the Poisson ratio u, the salinity s and the compressive strength Ec of the high-salinity salinized soil; determining the initial precipitation temperature Tm of the high-salinity salinized soil, and determining the moisture content w0 of the high-salinity salinized soil when T=Tf=0 DEG C; through field in situ testing, determining the minimum temperature T of the high-salinity salinized soil during cool-down; determining the phase-unchanged moisture ratio wu1 of the high-salinity salinized water during precipitation of crystalized salt; determining the unfrozen moisture ratio wu2 of the high-salinity salinized water during ice-water phase change; calculating the salinity-frost heaving force sigma e of the high-salinity salinized water through the following formula.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Extrusion method of porphyra haitanensis seed vegetables for repeatedly releasing carpospores

ActiveCN109156335AIncrease profitAddress deficienciesCultivating equipmentsSeaweed cultivationSporePorphyra

The invention discloses an extrusion method of porphyra haitanensis seed vegetables for repeatedly releasing carpospores. The method comprises the following steps: maturation promoting is performed onthe porphyra haitanensis seed vegetables, the moisture ratio of the seed vegetables after maturation promoting is 25-35%, and the area ratio of deep red patches to the whole thallus is about 15%; theseed vegetables after maturation promoting are put into seawater to release the carpospores, and the carpospores are inoculated on conches; the porphyra after releasing the carpospores is fished out,and packed into a double-layer plastic net bag after the porphyra is washed, and then sent to an extrusion apparatus to be subjected to extrusion, and the seawater after the porphyra is washed and the extrusion water are combined and inoculated on conches as a spore water; and the moisture ratio of the extruded porphyra is made to be 25-35% through water evaporating, then the porphyra can be preserved as the seed vegetables and can continue to release the carpospores as the seed vegetables. According to carpospores repeated releasing of the porphyra haitanensis seed vegetables, the deficiencyof seed vegetable insufficiency is solved, and the utilization rate of specific high-quality seed vegetables is improved. The method has the advantages of convenient operations and simple managements, and the efficiency and the benefit of seedling-raising and cultivation can be significantly improved.

Owner:NINGBO UNIV

Method, device and equipment for obtaining moisture ratio of agricultural product based on different drying stages

ActiveCN112989554AImprove computing efficiencyAccurate predictionDesign optimisation/simulationSpecial data processing applicationsSoil scienceAgricultural engineering

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Dehumidifying device special for industry

InactiveCN107906633ASimple structureOptimization principleMechanical apparatusCondensate preventionEngineeringHeat exchanger

The invention discloses a dehumidifying device special for industry. The dehumidifying device comprises a device shell which is internally provided with a fan, a compressor, a heat exchanger and a controller. The compressor communicates with the heat exchanger, and the compressor communicates with the fan while communicating with the heat exchanger. The fan, the compressor, the heat exchanger areconnected with the controller. According to the dehumidifying device, the structure is simple, the principle is simple, the manufacturing cost is low, and the power consumption is low; and meanwhile,the air temperature is not changed, thus the temperature keeps constant all the time, the moisture proportion in air is decreased through a dehumidifier, and the drug quality is ensured accordingly.

Owner:刘琳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com