Control method for adding water in mixture in sintering production

A control method and mixing material technology, applied in the flow control of electric devices, etc., can solve the problems of unstable concentration of industrial sludge and great difficulty in controlling the amount of water added, and achieve reduced fluctuations, stable control, and true and effective data Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

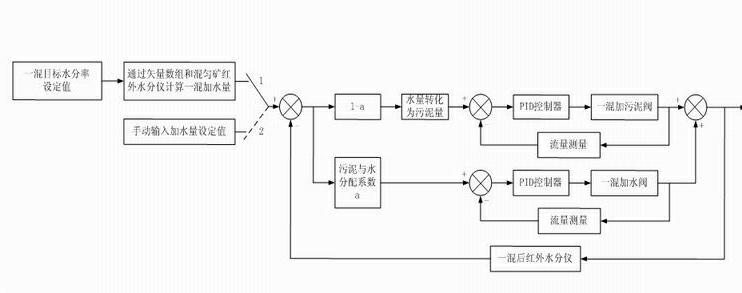

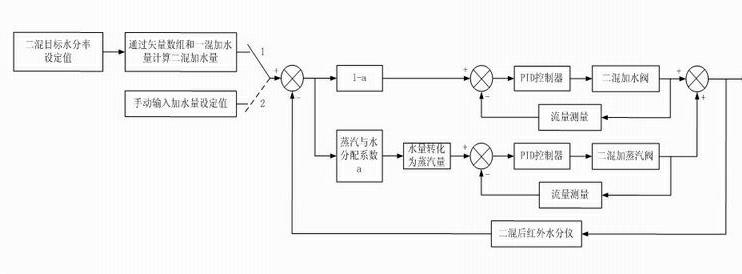

[0033] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

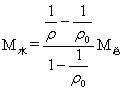

[0034] A control method for adding water to a mixture in sintering production, comprising the following process steps: first step, real-time measurement of the weight of various raw materials, sludge flow, sludge density, flow of water and steam, and water content of various raw materials; The second step is to filter the measured values to reduce the influence of data fluctuations on the control; the third step is to calculate and judge the degree of lime digestion; the fourth step is to establish an array of material tracking, including the weight of water and each The weight of raw materials; the fifth step, calculate the water content before mixing; the sixth step, calculate the water content in the sludge; the seventh step, according to the water content of the mixed material incoming material and the target value, calculate the amount of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com