Highroad pavement base and roadbed material containing slag fly ash of coal-fired power plant and stabilized by levigated lime

A technology for coal-fired power plants and highway bases, which is applied in the field of inorganic materials and can solve the problems of complex patent production and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: Get 1400g coal-fired power plant waste slag fly ash and add ground lime 1-2%, add water to make its moisture content be 20%

[0017] Test blocks 1, 2, 3, 4, 5, 6 were prepared. The average unconfined compressive strength measured after 7-day standard curing and saturated with water for 24 hours is 1.5Mpa. 95% guarantee rate is 0.9Mpa.

Embodiment 2

[0018] Embodiment 2: Get 1400g coal-fired power plant waste slag fly ash and add ground lime 2-5%, add water to make its moisture content be 30%

[0019] Test blocks 1, 2, 3, 4, 5, 6 were prepared. The average unconfined compressive strength measured after 7-day standard curing and water saturation for 24 hours is 1.9Mpa. 95% guarantee rate is 1.3Mpa.

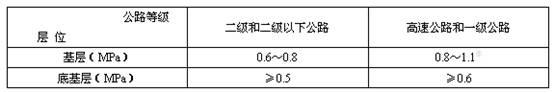

[0020] According to the industry standard issued by the Ministry of Communications of the People's Republic of China "Technical Specifications for Highway Pavement Base Construction" (JTJ034-2000), the compressive strength standard of fly ash mixture:

[0021]

[0022] It is stipulated that the base layer of highways and first-class highways can reach 1.1 Mpa, and the invention can achieve unconfined compressive strength of 0.9 Mpa by mixing 1-10% of ground lime, which fully meets the standard.

[0023] To sum up, the present invention provides a new type of inorganic material with higher strength and lower price, which ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com