Method for producing poliarization substrate

A manufacturing method and a technology for polarizing plates, which are applied in polarizing elements, chemical instruments and methods, instruments, etc., can solve problems such as image distortion, and achieve the effect of less defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

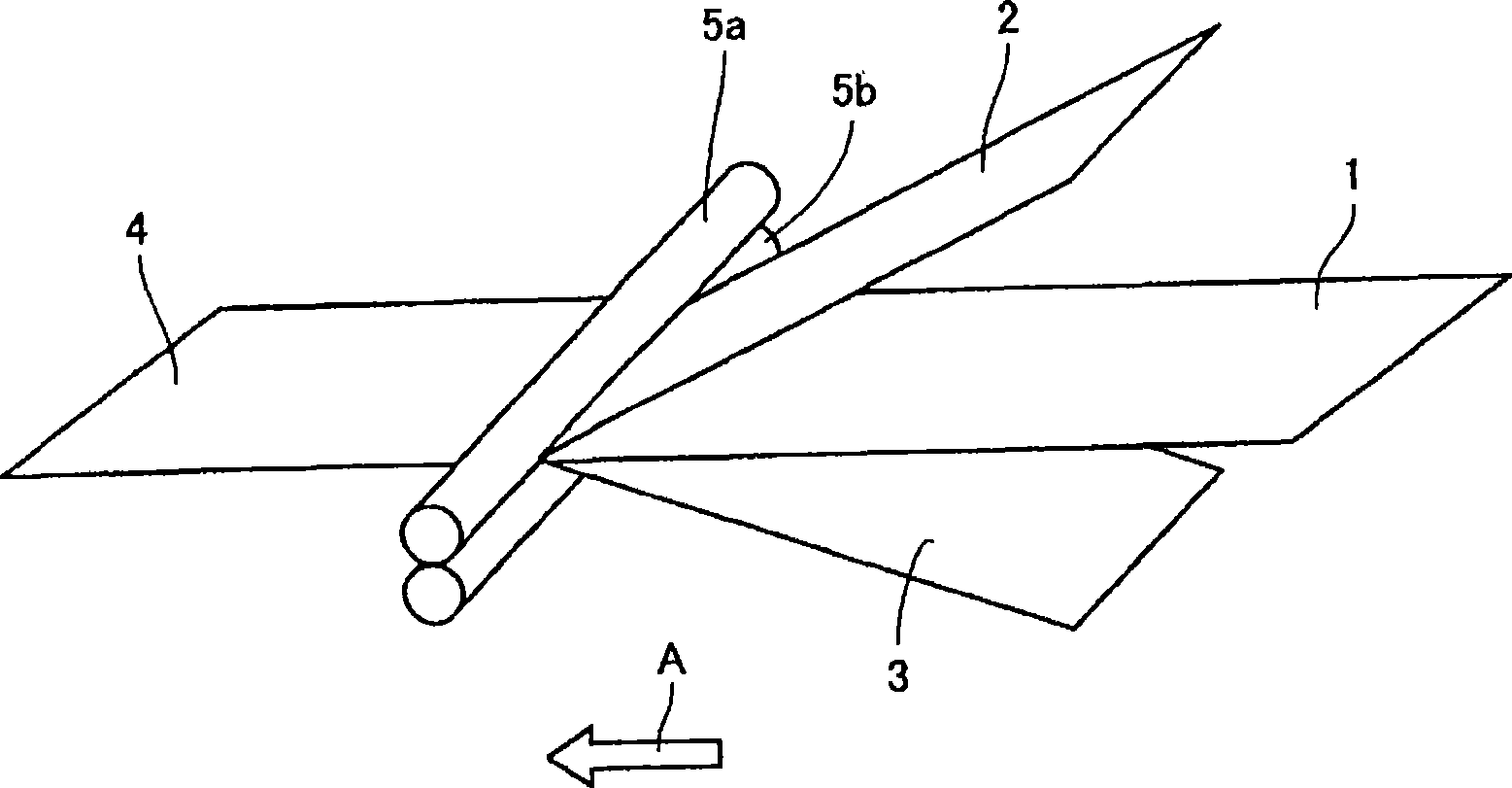

Method used

Image

Examples

experiment example 1

[0057] With the polyvinyl alcohol film having an average degree of polymerization of about 2400, a degree of saponification of 99.9% or more, and a thickness of 75 μm in a tense state, it is soaked and swollen in pure water at 30°C, and stretched in the longitudinal direction until stretched. The magnification is 1.3 times. With the polyvinyl alcohol film kept at the above stretch ratio, it was dyed in an aqueous solution containing iodine and potassium iodide (iodine: potassium iodide: water = 0.05:2:100 (weight ratio)) at 30° C. After cross-linking treatment in an aqueous solution containing potassium iodide and boric acid (potassium iodide: boric acid: water = 12:5:100 (weight ratio)) at 54°C and stretching at a total ratio of 5.6 times, in pure water at 12°C Cleaning. Make the polyvinyl alcohol film after cleaning pass through these 3 drying furnaces that temperature is maintained at 65 ℃, 75 ℃ and 85 ℃ successively, be dry under such condition that total residence time is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com