Train compressed gas treatment equipment and method

A technology for compressing gas and processing equipment, which is applied in the field of compressed gas processing equipment for trains. It can solve the problems of substandard gas quality, high cost of gas processing equipment, and the influence of gas transmission pipelines or components flowing through, so as to prolong the service life, The effect of reducing testing and operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

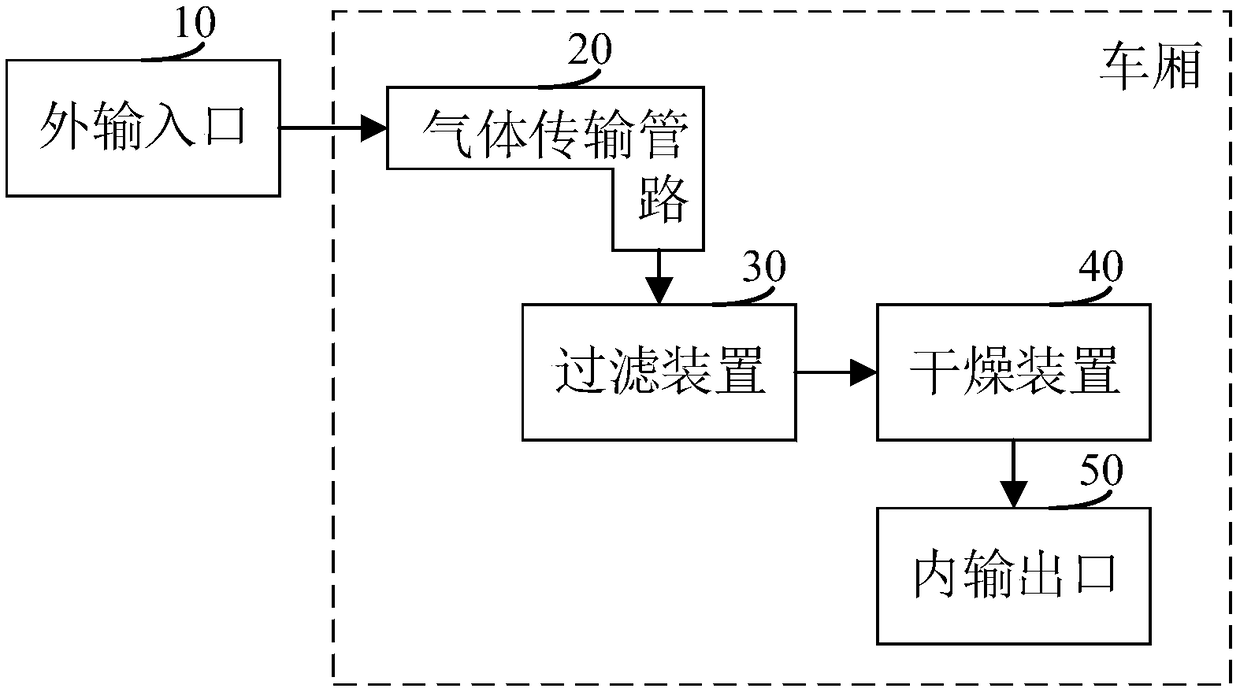

[0054] The core of the present invention is to provide a train compressed gas processing equipment and processing method. By setting the external input port of compressed gas at a suitable position, the input compressed gas is processed successively through a filter device and a drying device, so that after processing The compressed gas meets the preset gas quality requirements and the water content is as low as the preset ratio. It can make full use of the on-board equipment to process the input compressed gas, without adding external compressed gas processing equipment, reducing the cost of testing and operation and maintenance, and prolonging the service life of related components.

[0055] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com