Polysiloxane-polycarbonate copolymer compositions

A technology of siloxane copolymer and polycarbonate, applied in the direction of cabinet/cabinet/drawer parts, etc., can solve the problems of large size, loss of expected performance, and reduction of impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

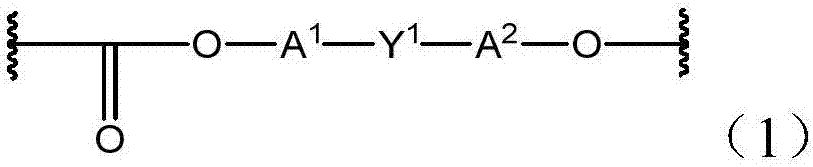

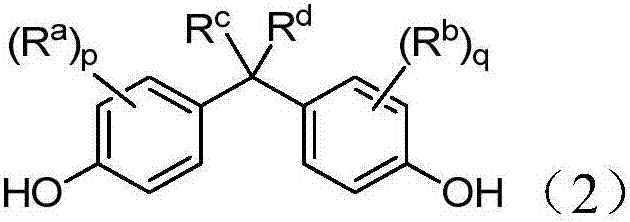

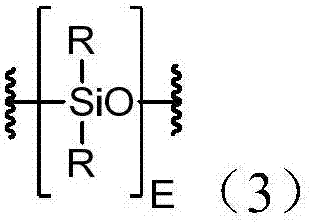

Method used

Image

Examples

Embodiment 1

[0158] Example 1. Compositions comprising polycarbonate and PC-siloxane copolymer

[0159] Varying the total amount of siloxane (wt %) from the two PC-siloxane copolymer sources, and varying the ratio of the two copolymers (compositions 1-4; Table 4), a series of polycarbonate compositions were prepared . Impact and appearance properties were evaluated. An increase in the PC-Si-1:PC-Si-2 ratio resulted in improved flow mark visibility. As the amount of PC-siloxane copolymer increases, so does the impact performance, as evidenced by the increase in NII energy. Flame retardancy was also excellent in all compositions.

[0160] Table 4.

[0161] combination

Embodiment 2

[0162] Example 2. Compositions comprising polycarbonate and impact modifier

[0163] Additional studies included comparisons of compositions with different amounts of PC-siloxane copolymer and impact modifier (Table 5). The incorporation of impact modifier IM-1 resulted in high flow mark visibility, lower ductile-brittle transition temperature and high impact energy (compositions 5 and 8). However, the type of impact modifier incorporated in compositions with lower amounts of PC-polysiloxane had an impact on impact and appearance properties, as compared to compositions with IM-2 (compositions 9 and 10) In comparison, the compositions with IM-1 (compositions 6 and 7) have improved impact and appearance properties. Furthermore, the deep black color power remained high in all compositions prepared.

[0164] table 5.

[0165]

Embodiment 3

[0166] Example 3. Compositions comprising different flame retardants

[0167] Composition 2 was modified to replace KSS with a different flame retardant. Replacing KSS with NaTs (also known as sulfonates) provided a composition with good mechanical properties but reduced flame retardancy (composition 11). Replacing KSS with phosphorus-based flame retardant BPADP resulted in lower HDT and impact properties (compositions 12 and 13). These data indicate that the use of KSS in the composition provides a composition with the requisite mechanical properties and flame retardancy required for polycarbonate compositions suitable for thin wall applications. Comparing compositions 2 and 11, it can be noticed that the use of KSS, a sulfonate flame retardant, provides superior flame retardancy over NaTs, also a sulfonate flame retardant. Composition 13 shows that by using BPADP, this grade can have V0@1.2mm but lose RTI w / Imp. Therefore, KSS can impart FR performance at V0@1.2mm, where ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| brittleness temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| brittleness temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com