Polycarbonate composition and application of polysiloxane-polycarbonate copolymer in improving toughness and liquidity of mineral-filled polycarbonate

A polycarbonate and polysiloxane technology, applied in the field of polymer materials, can solve problems such as the influence of mineral-filled polycarbonate on mechanical properties, and achieve the effects of good melt index stability, not easy to deform, and stable fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention is further illustrated by the following examples, but the present invention is not limited by the following examples.

[0050] The sources of raw materials used in the present invention are as follows, but are not limited by the following raw materials.

[0051] Polycarbonate resin: 1300-10NP, LG Chem;

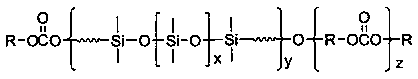

[0052] Polysiloxane-polycarbonate copolymer A: The degree of polymerization of the siloxane block in the polysiloxane-polycarbonate copolymer is 50, and the total siloxane content is 20%.

[0053] Polysiloxane-polycarbonate copolymer B: the degree of polymerization of the siloxane block in the polysiloxane-polycarbonate copolymer is 34, and the total siloxane content is 25%.

[0054] Lubricant: LOXIOL P 861 / 3.5;

[0055] Antioxidant: CHINOX 1076;

[0056] Talc powder: particle size 1-2 microns;

[0057] The preparation method of the polycarbonate composition of embodiment and comparative example: mix polysiloxane-polycarbonate copolymer, polyca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com