Caterpillar type straw pick-up vehicle

A crawler and straw technology, applied in the field of agricultural machinery, can solve the problems of difficult collection of rice straw, inability to harvest and leave the field, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

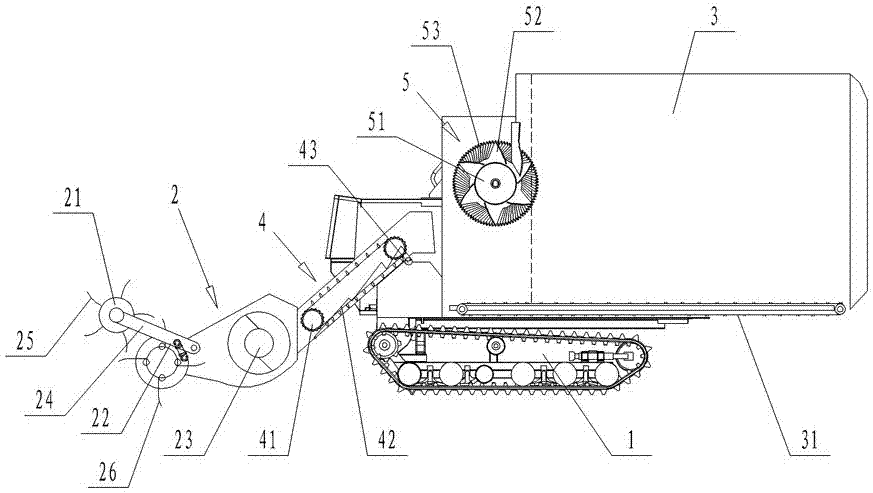

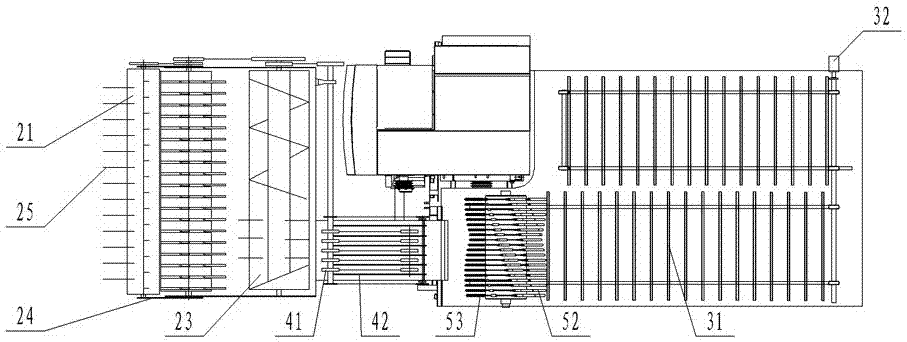

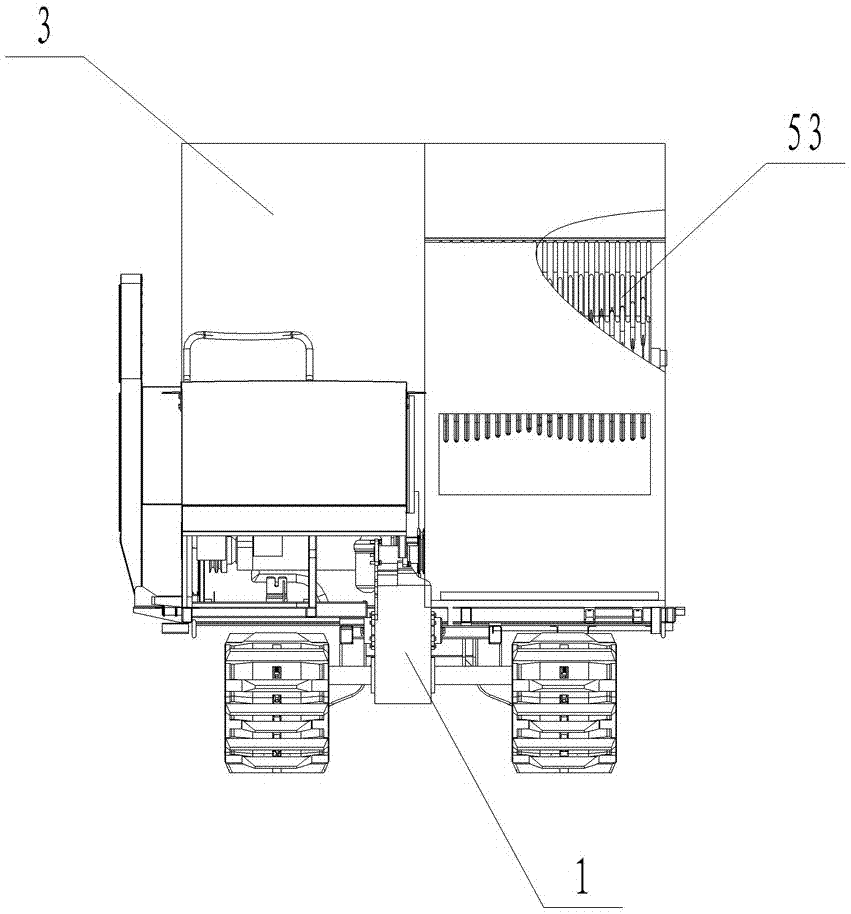

[0018] The crawler-type stalk picking vehicle of the present embodiment, as figure 1 , figure 2 and image 3 As shown, it includes a crawler chassis 1, a pick-up platform 2, a grass collection box 3, a driver's cab and a power system, and a conveying bridge 4 is communicated between the pick-up platform 2 and the grass collection box 3.

[0019] Picking up platform 2 is located at the crawler chassis ahead, grass collection box 3 is fixed on the crawler chassis, and driver's cab and power system are installed on the crawler chassis 1.

[0020] Picking up platform 2 comprises the auger 23 that is located at the weeding roller shaft 21 and the picking up roller shaft 22 that are located at the front of the picking up platform and is located at the picking up platform rear, and the auger 23 is adjacent to the entrance of the bridge 4 and is transported.

[0021] The two ends of the grass pulling roller shaft 21 are hinged on the pick-up platform 2 through the connecting rod 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com