Fluid reinforcement structure, one-way valve, intelligent mosquito killing equipment, blow drier, fan and propeller of airplane and ship or submarine

A one-way valve and fluid technology, applied in mechanical equipment, devices for catching or killing insects, electric speed/acceleration control, etc., can solve the problem of increasing the wind pressure at the end of the fan blowing channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

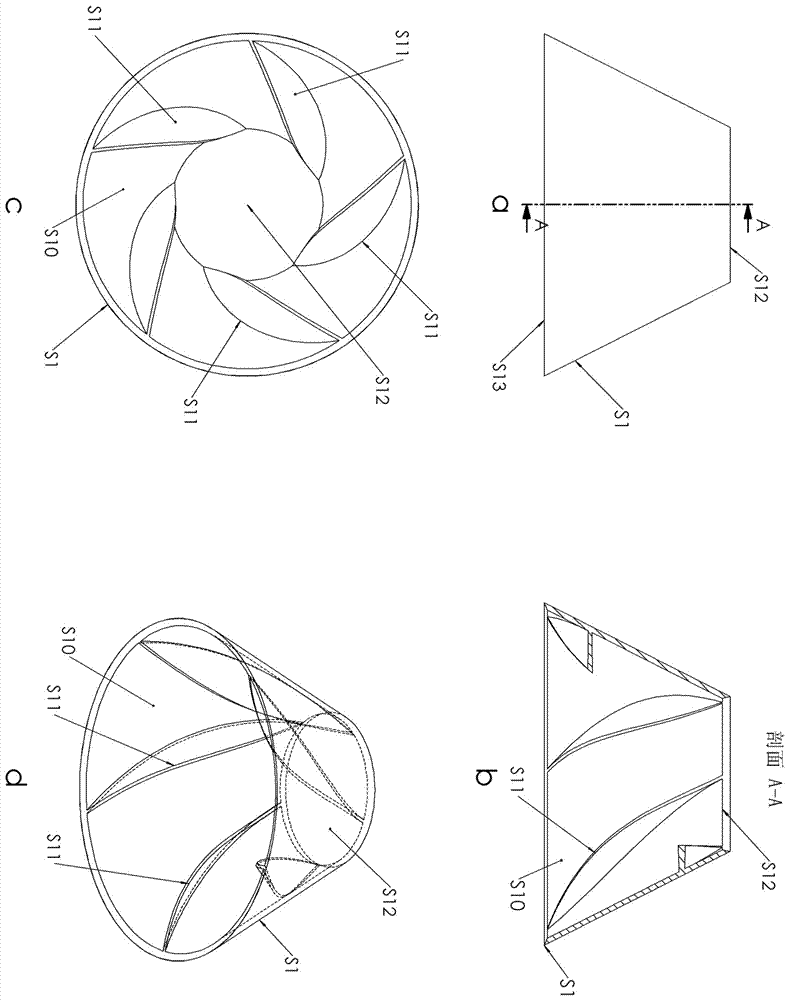

[0052] Implementation example 1, such as figure 1 As shown, the fluid booster structure, S1 is the body of the one-way valve fluid booster structure, S10 is the conical cavity, S11 is the spiral flow guide structure, and S12 is the small end of the conical cavity, which is the one-way valve fluid booster structure S13 is the large end of the conical cavity, which is the fluid inlet of the fluid booster structure of the one-way valve; the spiral guide structure is a spiral plate, the number of spiral plates is 5, and the height of the spiral plate is converted into a coordinate curve as follows: Arc, a line that bends in one direction.

Embodiment 2

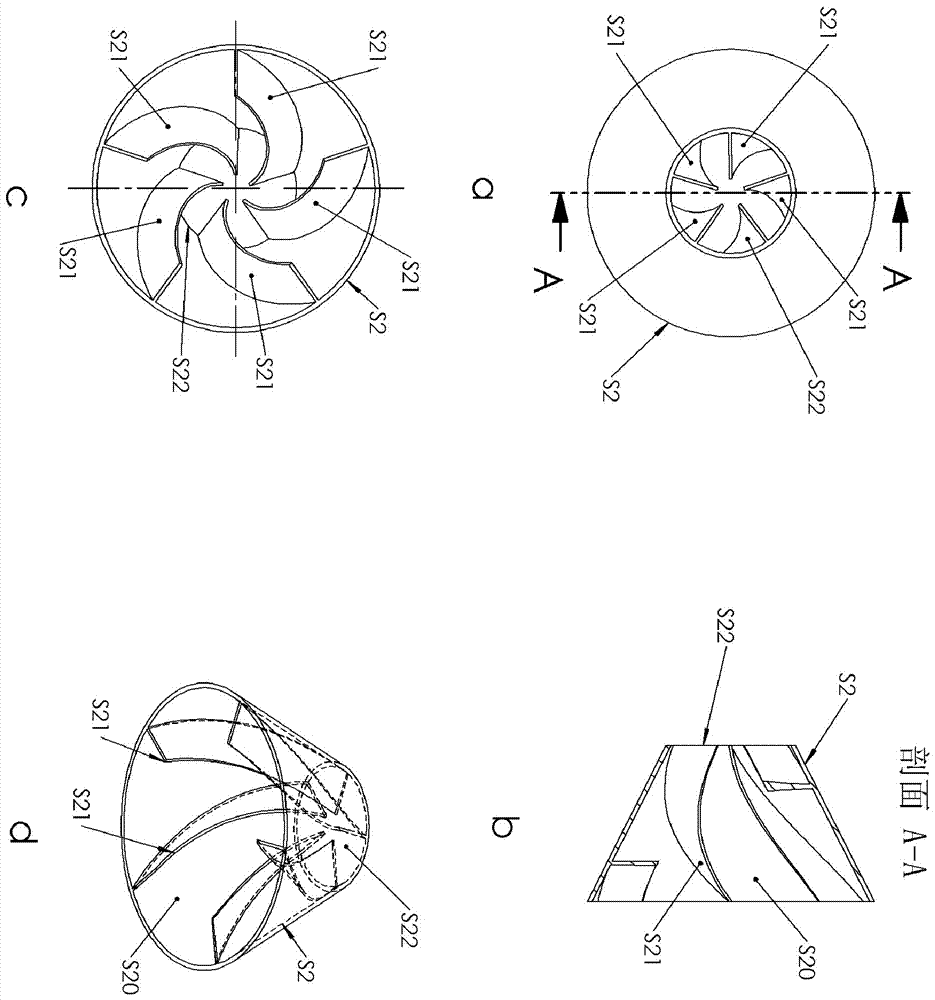

[0053] Implementation example 2, such as figure 2 As shown, the fluid booster structure, S1 is the body of the one-way valve fluid booster structure, S10 is the conical cavity, S11 is the spiral flow guide structure, and S12 is the small end of the conical cavity, which is the one-way valve fluid booster structure S23 is the large end of the conical cavity, which is the fluid inlet of the fluid booster structure of the one-way valve; the spiral guide structure is a spiral plate, the number of spiral plates is 5, and the height of the spiral plate is converted into a coordinate curve as follows: The straight line, that is to say the height of the spiral plate in this embodiment is constant.

Embodiment 3

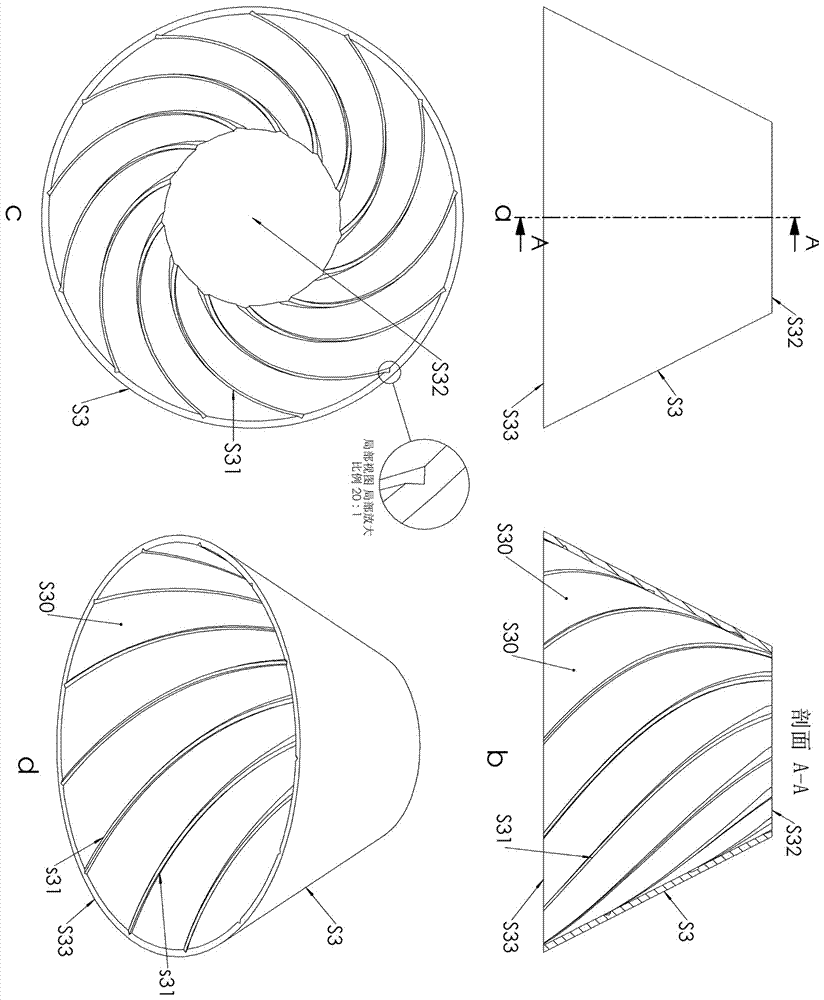

[0054] Implement Example 3, such as image 3 As shown, the fluid booster structure, S3 is the body of the one-way valve fluid booster structure, S30 is the conical cavity, S31 is the spiral guide structure, and S32 is the small end of the conical cavity, which is the one-way valve fluid booster structure S33 is the large end of the tapered cavity, which is the fluid inlet of the fluid booster structure of the one-way valve; the spiral guide structure is a spiral groove, the number of spiral plates is 12, and the spiral groove is located in a V-shaped groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com