Construction method of protective layer on surface of wind turbine blade mold

A wind turbine blade and construction method technology, applied in the manufacturing field, can solve the problems of film damage, easily damaged butt joints, damage, etc., and achieve the effects of product quality assurance, reduction of peeling load, and convenient recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

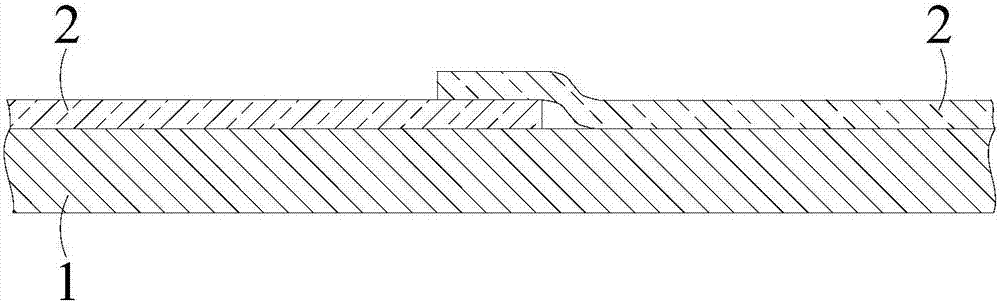

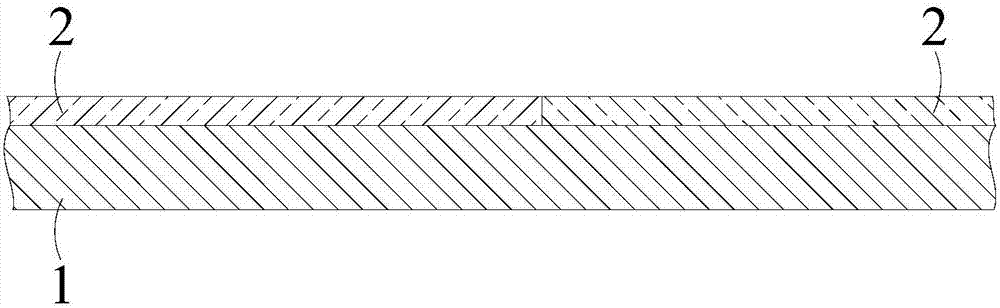

[0033] The technical solutions provided by the present invention will be described in detail below through specific embodiments of the present invention in conjunction with the accompanying drawings, so that those skilled in the art can have a clearer understanding of the present invention. It should be noted that the technical solutions provided in the following embodiments and the drawings in the description are only used to illustrate the present invention, and are not used to limit the present invention. The same elements and steps will be described with the same reference signs. In the following embodiments and drawings, components and steps not directly related to the present invention are omitted and not shown; and the dimensional relationship among the components in the drawings is only for easy understanding, not for limiting the actual ratio.

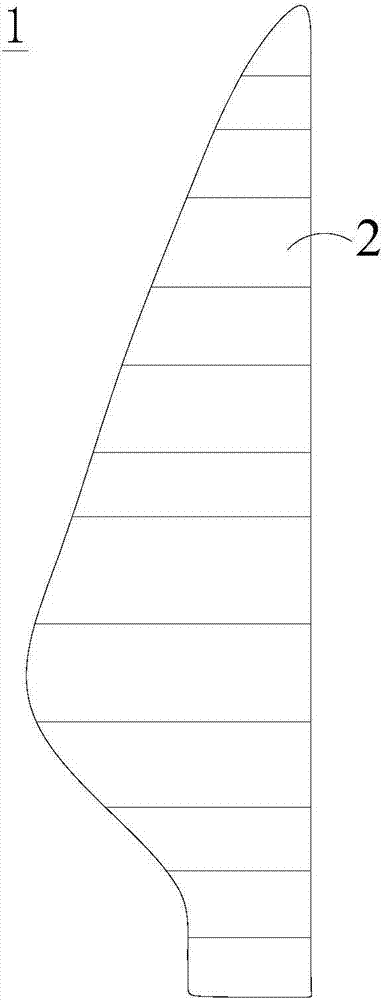

[0034] The present invention provides a method for constructing a protective layer on the surface of a wind turbine blade mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com