Subsectional braking force controlling method based on velocity

A control method and braking force technology, applied in the control drive, railway braking system, electric vehicle, etc., can solve the problems of reduced electric braking capacity, increased brake pad wear and maintenance cost, etc., to reduce wear and later maintenance. cost, avoid inconsistent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

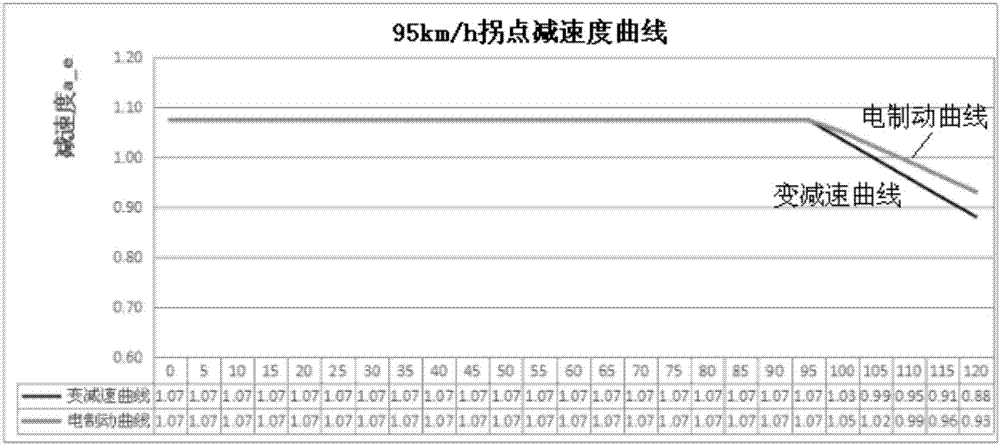

[0042] In the present invention, the speed is divided into a low-speed section of 0-95km / h and a high-speed section of 95-120km / h.

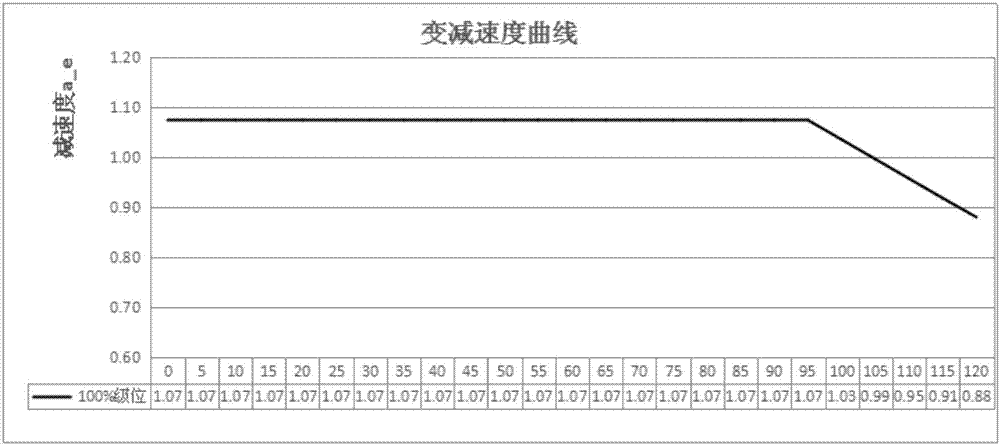

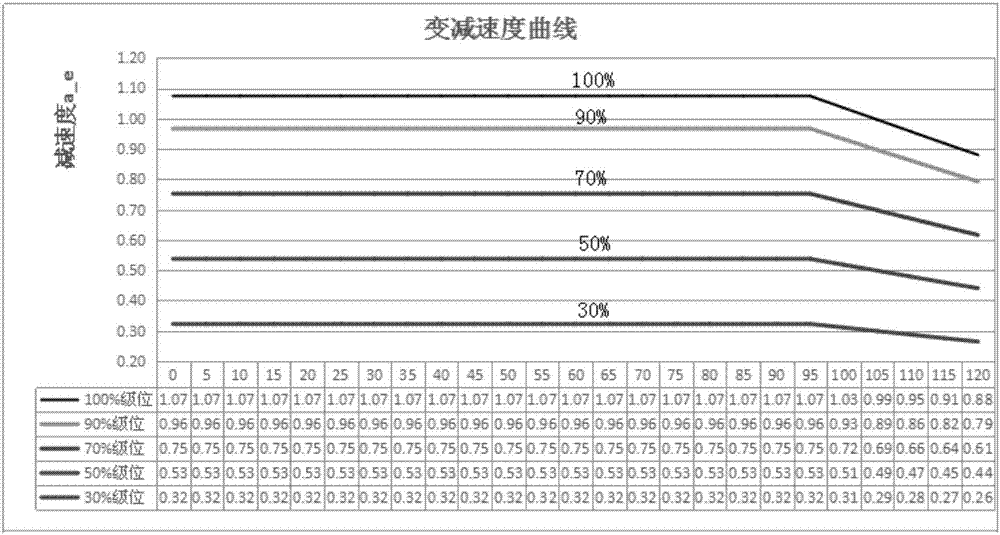

[0043] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a speed-based section braking force control method includes the following steps.

[0044] Step 1, draw the equivalent deceleration curve of electric braking.

[0045] First take the speed V as the horizontal axis, and the value range of the speed is 0-120km / h; then take the deceleration a as the vertical axis, draw as image 3 The electric braking equivalent deceleration curve under the electric braking constant power characteristic shown.

[0046] 100% electric braking force is used when drawing the electric braking equivalent deceleration curve, that is, the maximum electric braking force is used.

[0047] In the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com