A kind of water-based attapulgite-based die-casting release agent and preparation method thereof

The technology of release agent and attapulgite is applied in the field of water-based attapulgite-based die-casting release agent and its preparation, which can solve the problems of operator's hands and feet, clothes stain, unfavorable long-distance transportation, unsuitable working environment, etc. Forgings are smooth and flat, and the process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

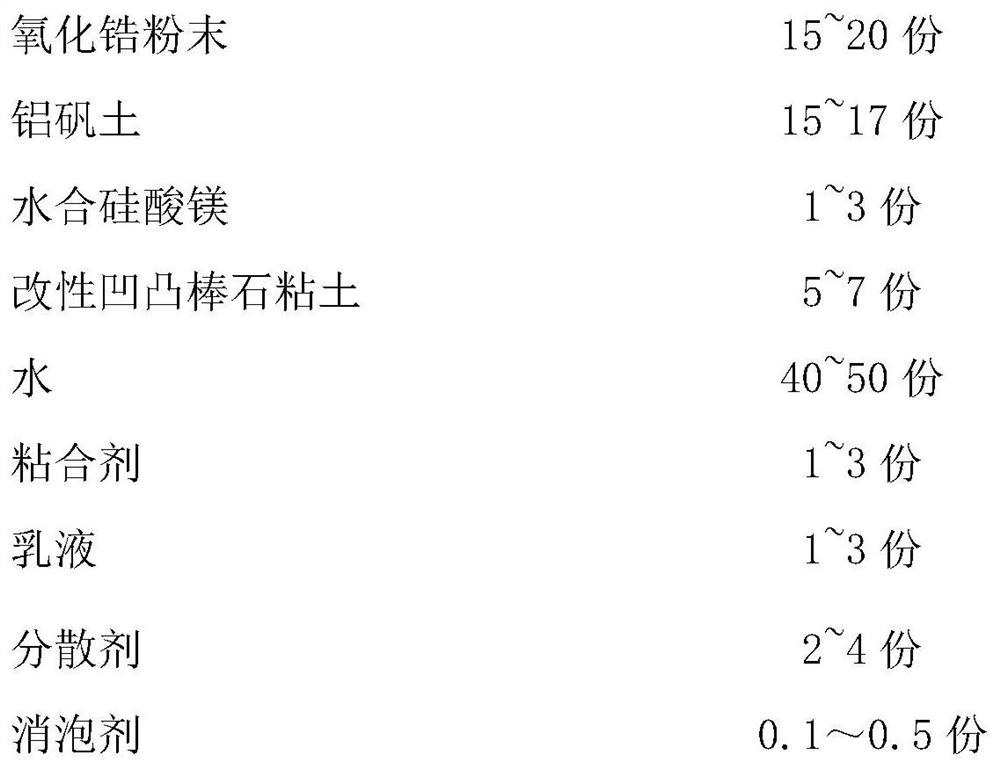

Embodiment 1

[0025] Add 15 parts of zirconia powder, 5 parts of modified attapulgite clay powder, 16 parts of bauxite, and 1 part of hydrated magnesium silicate to 45 parts of deionized water, stir at 1500-3000 rpm for 1-2 hours, and then Add 2 parts of adhesive, 2 parts of emulsion, 4 parts of dispersant and 0.2 part of defoamer, then fully stir with a cross blade stirrer, the stirring speed is 1500-3000 rpm, and the stirring time is 1-2h, to get Water-based attapulgite-based die-casting release agent, ready for use.

Embodiment 2

[0027] Add 20 parts of zirconia powder, 7 parts of modified attapulgite clay powder, 16 parts of bauxite, and 3 parts of hydrated magnesium silicate to 44 parts of deionized water and stir at 1500-3000 rpm for 1-2 hours. Then add 2 parts of adhesive, 3 parts of emulsion, 2 parts of dispersant and 0.3 part of defoamer, then fully stir with a cross blade stirrer, the stirring speed is 1500-3000 rpm, and the stirring time is 1-2h. A water-based attapulgite-based die-casting release agent was obtained for future use.

[0028] The mold release agent prepared by the method of the present invention is a water-based resin mold release agent, and its density obtained by measuring is 1.04-1.12g / cm 3 , pH value: 6.5 ~ 8.0.

[0029] Measured by the stability test, the results show that the suspension still has 99.5% after being placed for 15 days. The water-based release agent prepared by the present invention has good stability, which is beneficial to the uniform coating of the release ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com