A protective device for supersonic flame spraying

A technology of supersonic flame and protection device, applied in coating, fusion spraying, metal material coating process, etc., can solve the problems of reducing operator's work efficiency, heavy operator's physical load, and threatening workers' health, etc. The effect of ensuring personal health, simple structure and reducing body load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

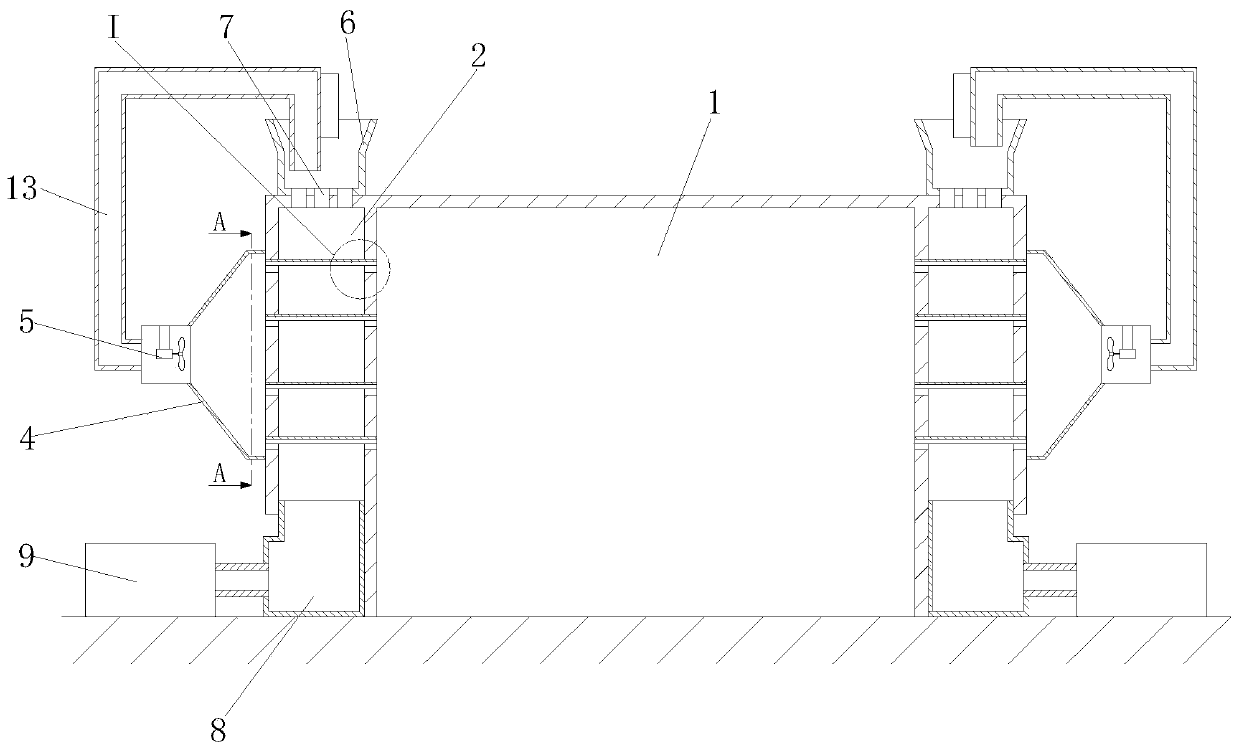

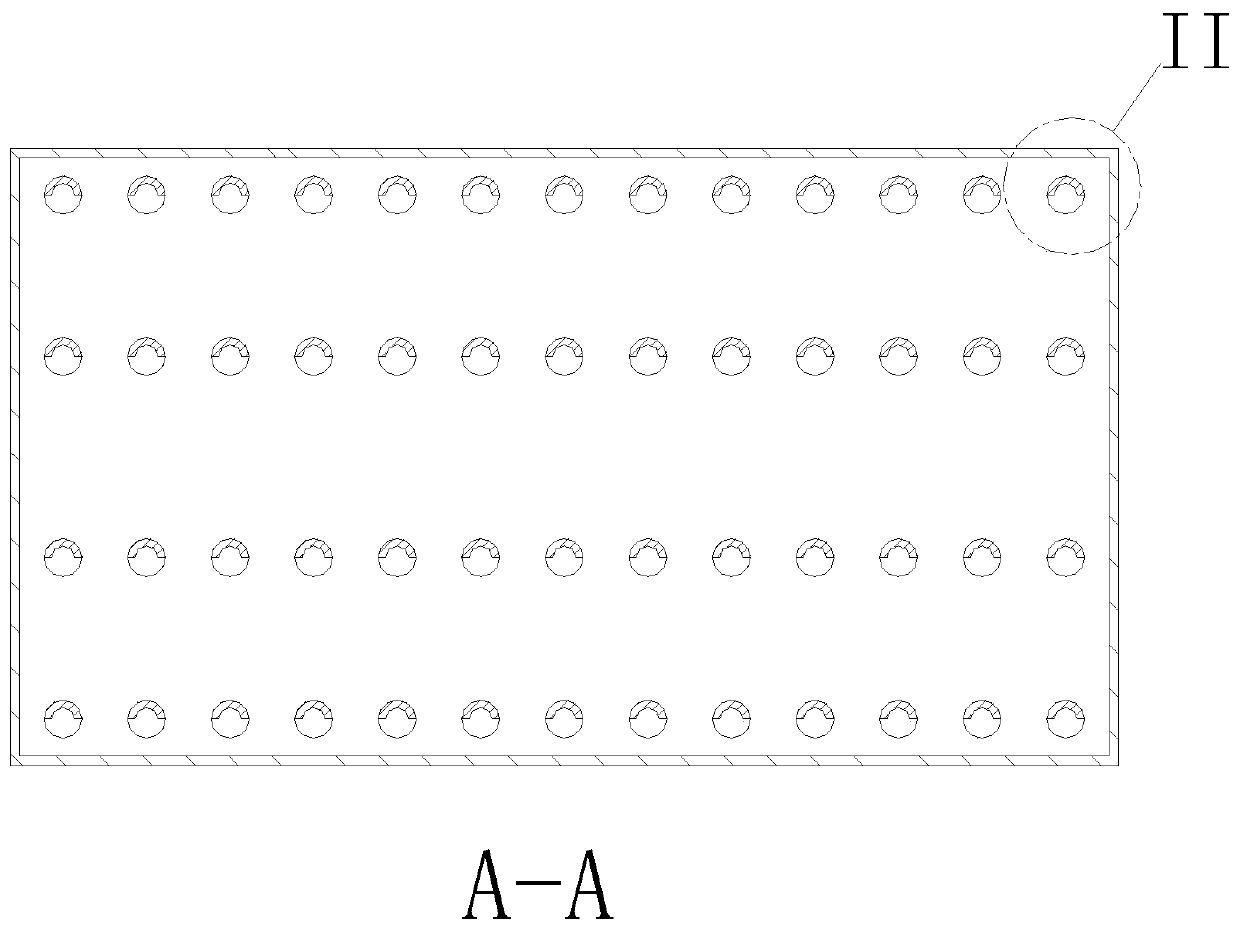

[0027] Such as Figure 1 to Figure 8 As shown, a protective device for supersonic flame spraying includes a casing 1, on which a symmetrically distributed water curtain absorption device for filtering exhaust gas is installed, and on the casing 1 is provided a spray gun for installation Working belt mechanism. The water curtain absorption device can realize the absorption between most of the harmful gas and water, and the transmission belt mechanism ensures that the supersonic flame spraying device can spray the workpiece in motion in the airtight casing 1 while ensuring a certain airtightness.

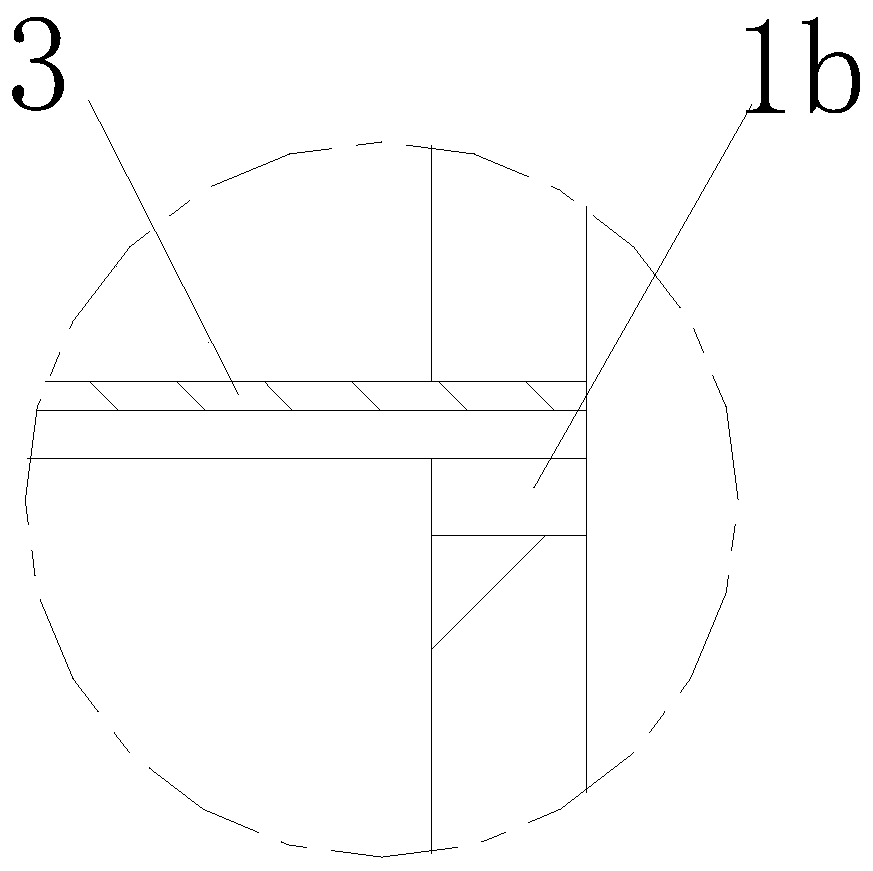

[0028] The water curtain absorbing device includes an absorption chamber 2 connected to the housing 1, a long tube 3 that is evenly spaced and connected to the interior of the housing 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com