A workpiece same potential temperature measuring device in a plasma vacuum coating chamber

A technology of vacuum coating and temperature measuring device, which is applied in vacuum evaporation coating, ion implantation coating, sputtering coating, etc., can solve the problems of uneven temperature distribution of plasma and surrounding environment, and can not accurately reflect the actual temperature of workpiece.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

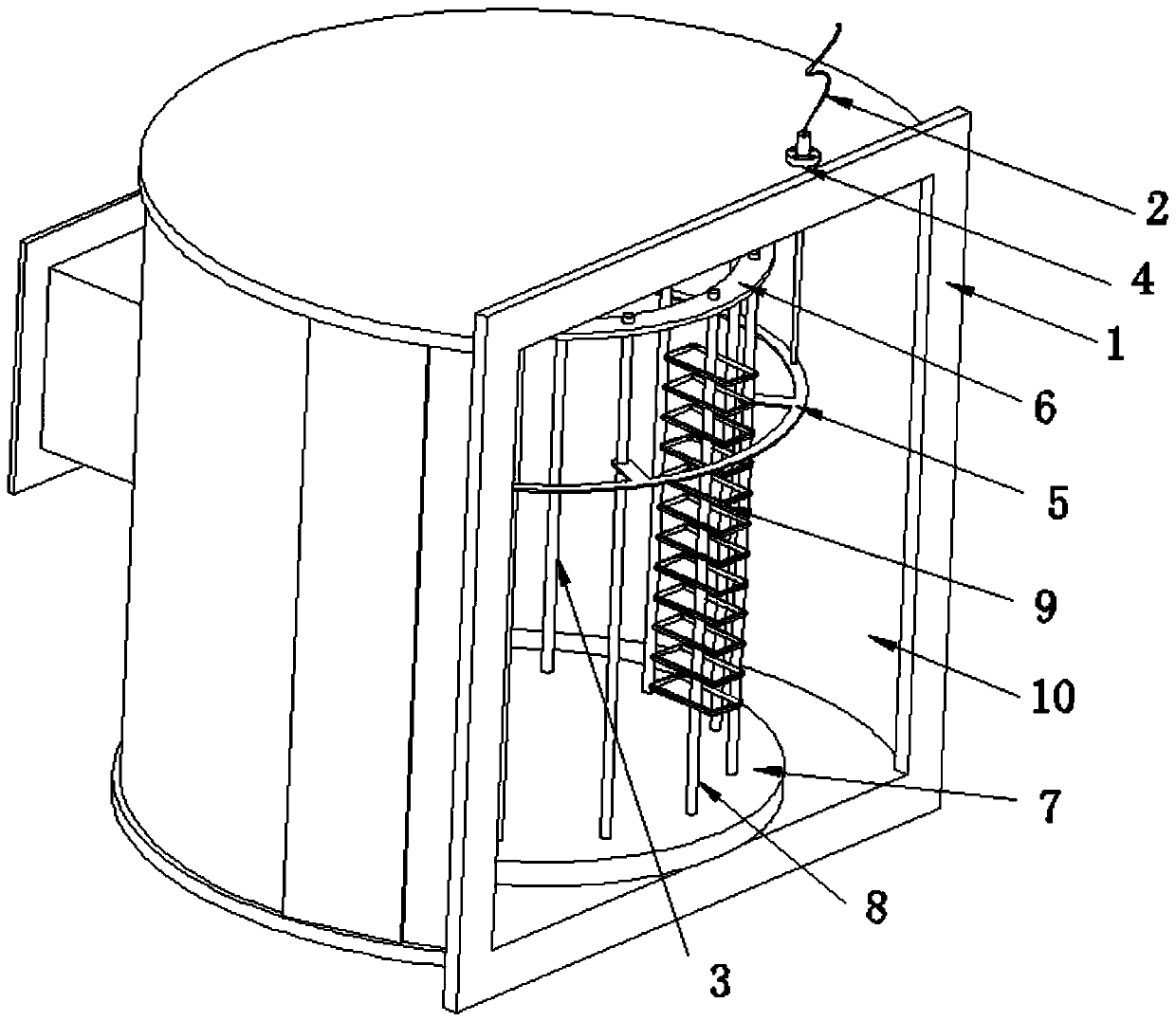

[0013] Such as figure 1 As shown, a workpiece same potential temperature measuring device in a plasma vacuum coating chamber includes a coating chamber tank body 1 and a temperature measuring thermocouple 2; a coating chamber cavity 10 is formed inside the coating chamber tank body 1; There are a workpiece rack 3 and a turntable, the workpiece rack 3 is fixed on the turntable 7, and can rotate synchronously with the turntable; the tank body 1 of the coating chamber is provided with an opening 4; Stretch into the coating chamber cavity 2 through the opening 4; the coating chamber cavity 10 is also provided with an annular heat conducting plate 5 horizontally arranged along the circumferential direction of the workpiece holder 3; the annular heat conducting plate 5 is also fixed on the workpiece holder 3 and can be The turntable rotates synchronously; the measuring end of the temperature measuring thermocouple 2 is in contact with the annular heat conducting plate 5; the outer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com