Novel connecting structure for subway tunnel and extended station and construction method of novel connecting structure

A technology for connecting structures and tunnels, applied in infrastructure engineering, tunnels, underwater structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

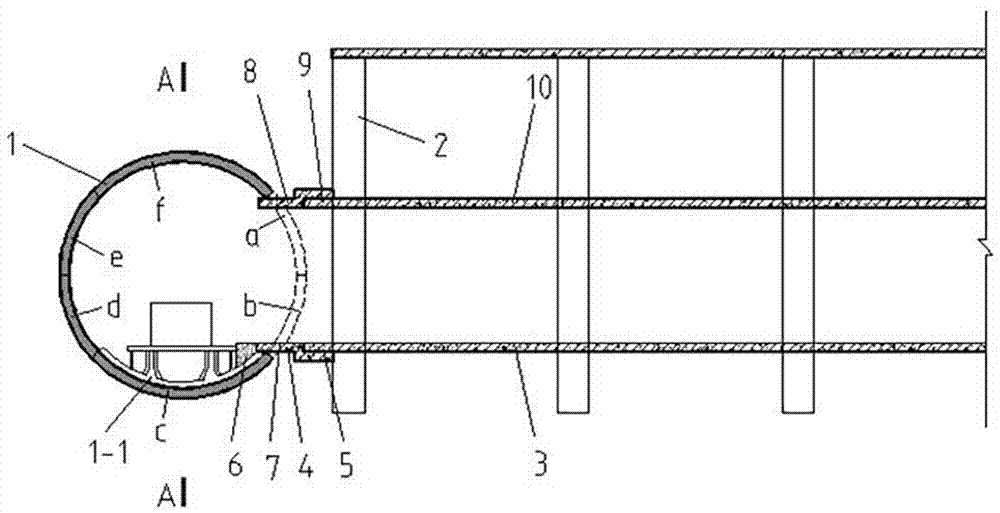

[0028] like figure 1 and 2 As shown, the present invention is a novel connecting structure between a subway tunnel and an extended station, comprising a tunnel gallery piece 1, a rail base 1-1, a load-bearing column 2, a prefabricated first bottom plate 3 on the bottom surface, a prefabricated second bottom plate 4 on the bottom surface, and a prefabricated bottom surface The third bottom plate 5, concrete leveling layer 6, waterproof material layer 7, prefabricated second bottom plate 8 on the top surface, prefabricated third bottom plate 9 on the top surface, prefabricated first bottom plate 10 and post-casting belt 11 on the top surface, special shield tunnel tube Corridor 1 is composed of 6 prefabricated standard segments a-f, and the connection sequence is clockwise from a to f, among which the standard segments a and b that are dismantled later form the opening of the platform.

Embodiment 2

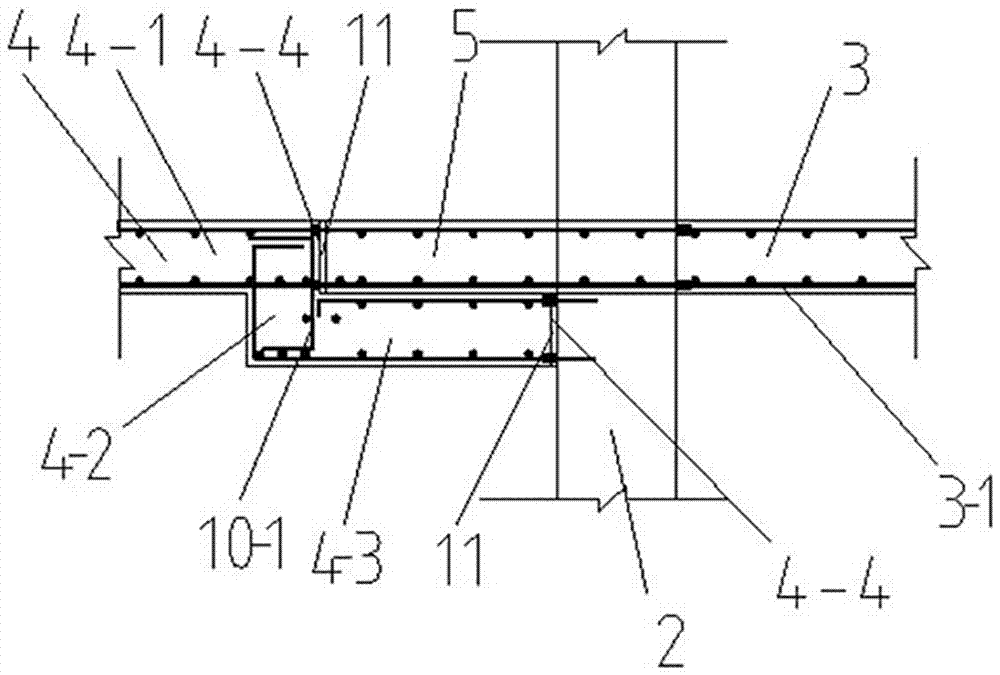

[0030] like image 3 and 5As shown, the connection between the special segment and the transfer station structure is divided into a top connection block and a bottom connection block. It consists of cast belt 11, the bottom prefabricated first base plate 3 is arranged on one side of the load-bearing column 2, the bottom prefabricated second base plate 4 and the bottom surface prefabricated third base plate 5 are arranged on the other side of the load-bearing column 2, the bottom prefabricated second floor is divided into The horizontal part 4-1, the vertical part 4-2 and the bending support part 4-3, the vertical part 4-2 and the prefabricated third base plate 5 on the bottom surface correspond to the connection gap to form a groove 4-4, and the post-casting tape is used later 11 connections.

Embodiment 3

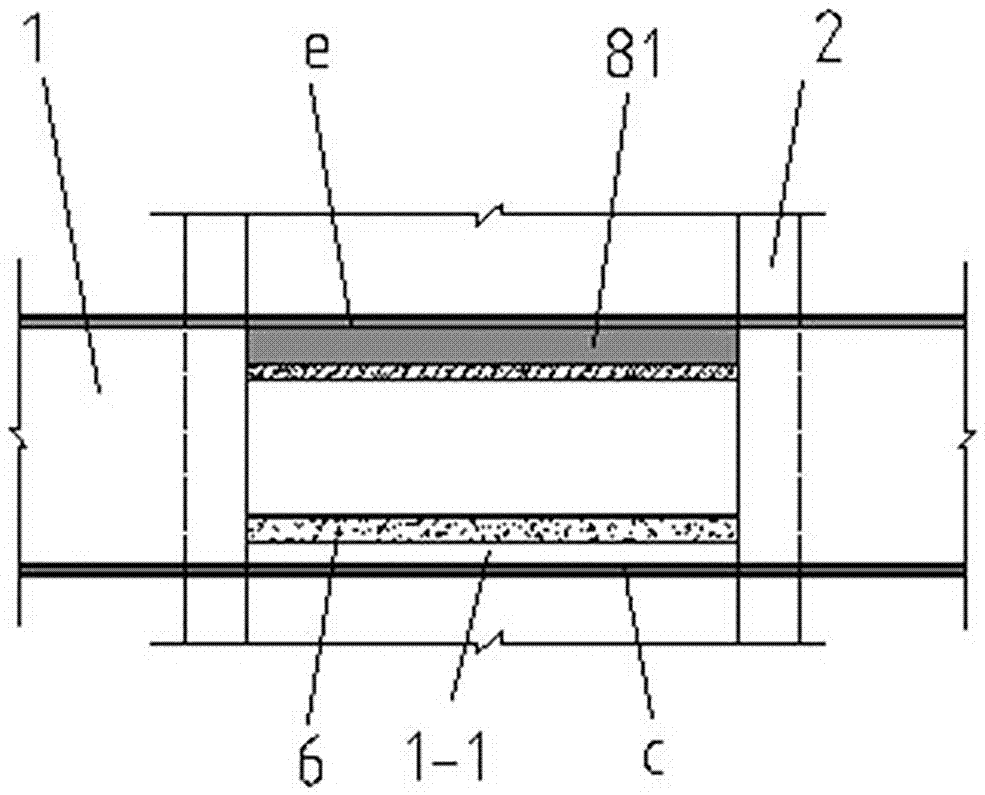

[0032] like Figure 4 and 6 As shown, the top connecting block connection is composed of the top prefabricated first bottom plate 10, the top prefabricated second bottom plate 8, the top prefabricated third bottom plate 9 and the post-casting belt 11, and the top prefabricated first bottom plate 10 is arranged on the load-bearing column 2, the top prefabricated second bottom plate 8 and the top prefabricated third bottom plate 9 are arranged on the other side of the load-bearing column 2, and the top prefabricated second floor is divided into a horizontal part 8-1 and a vertical part 8-2 And the bending support part 8-3, the vertical part 8-2 and the prefabricated third bottom plate 9 on the top surface correspond to the connection gap to form a groove 4-4, and then use the post-casting tape 11 to grout the connection, and add a case in the grout Water-expandable waterproof glue, concrete troweling layer 6 is set at the bottom of the tunnel pipe gallery, and the height is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com