Exhaust manifold for a two-stage engine charge air system

A technology for exhaust manifolds and engines, which is applied in the direction of engine components, machines/engines, exhaust devices, etc., and can solve problems such as limited space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Although the present invention is capable of various modifications and alternative forms, specific embodiments have been illustrated in the drawings by way of example and described in detail below. However, it is not intended to limit the invention to the specific embodiments described. On the contrary, the present invention is intended to cover all modifications, equivalent structures, and alternatives falling within the scope of the present invention defined by the appended claims.

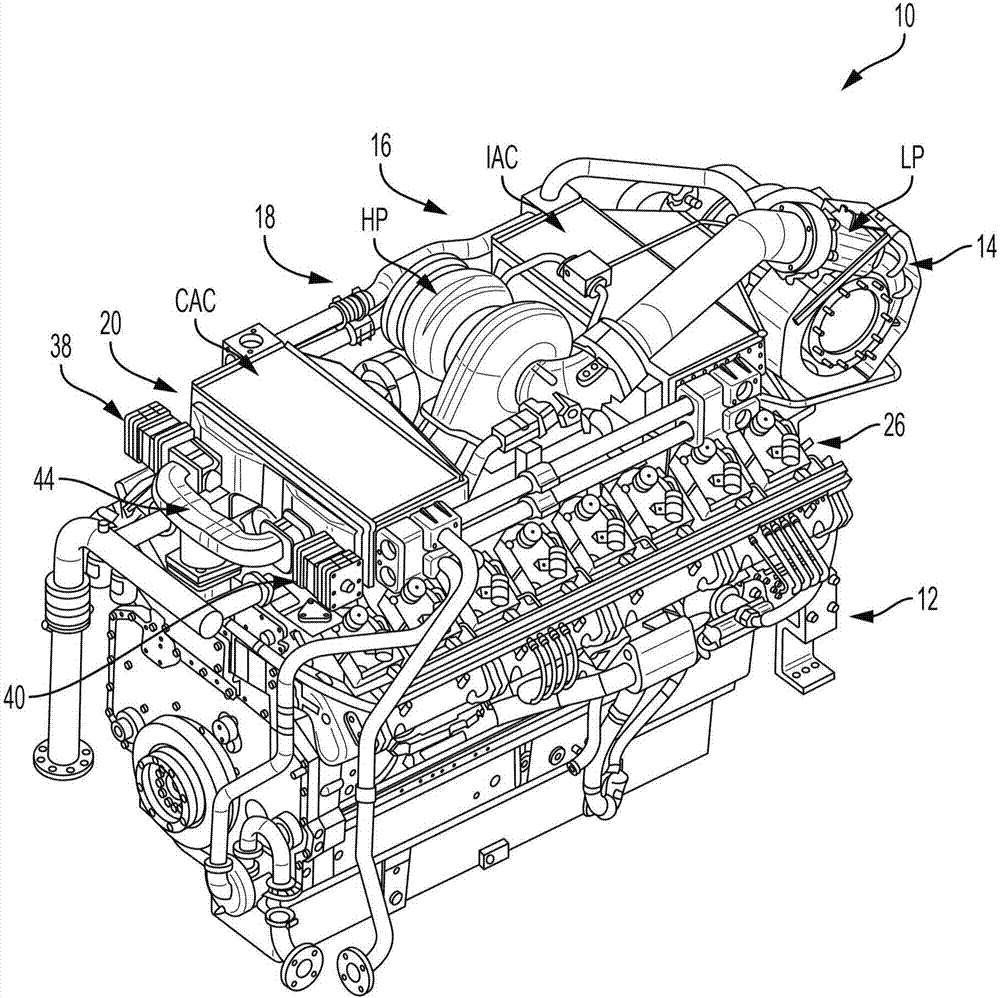

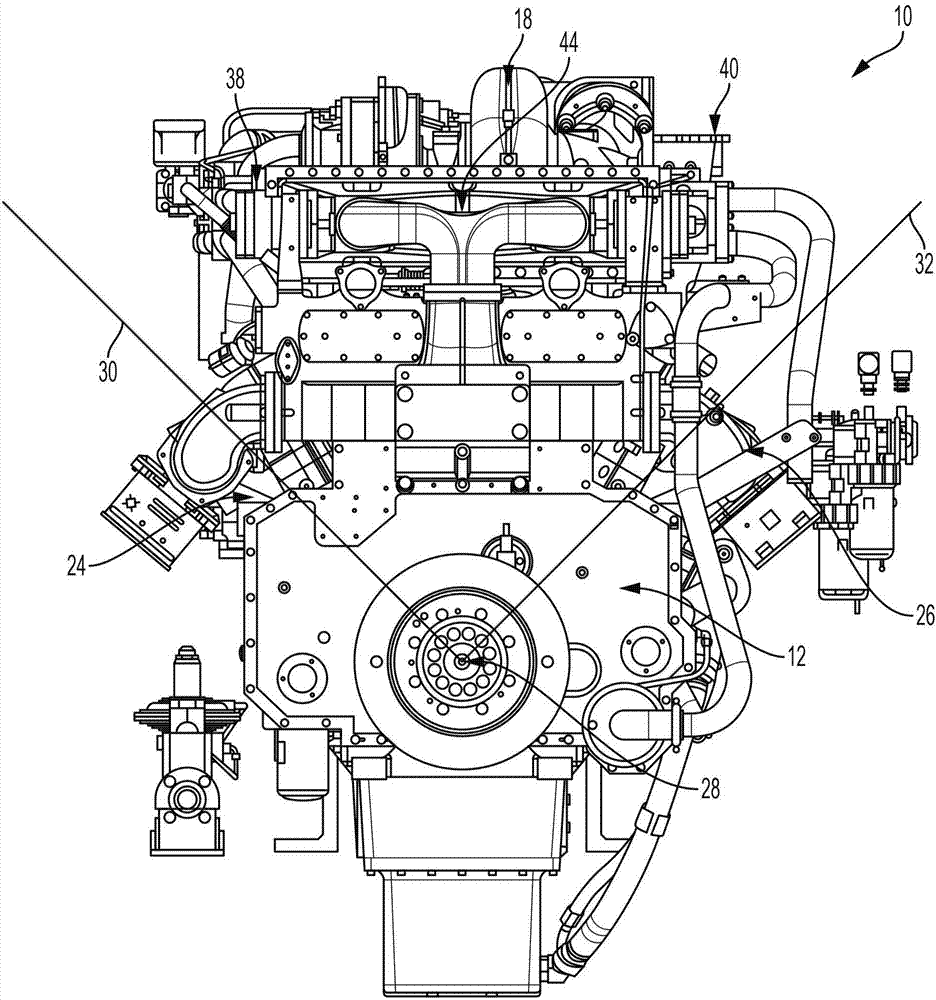

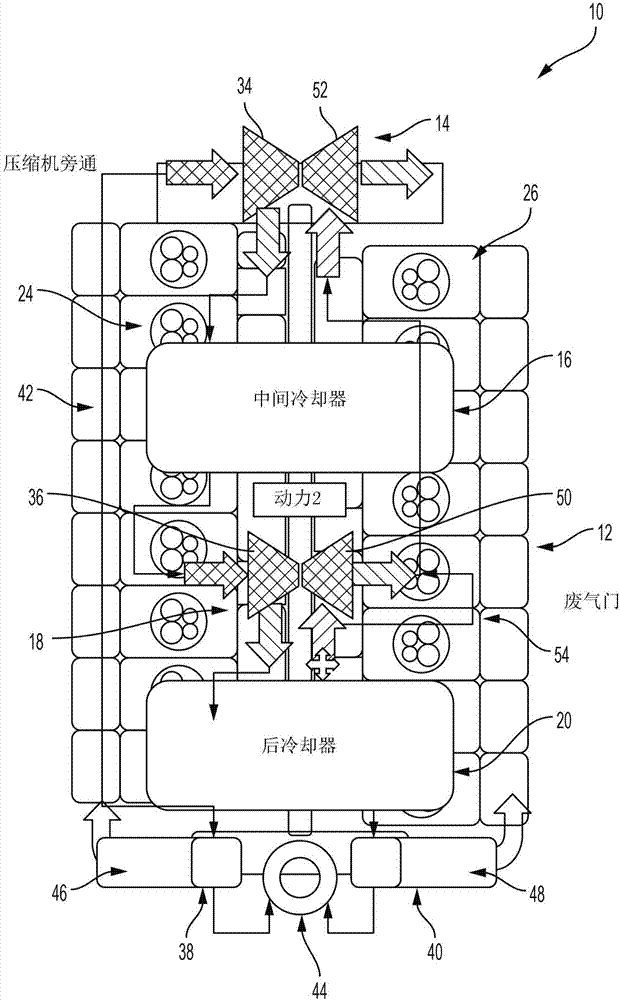

[0033] Figure 1-Figure 4 A two-stage turbocharging system according to the principles of the present disclosure is depicted. Generally, the system 10 includes a VEE-structure engine 12, a low-pressure turbocharger 14, an intermediate air cooler 16 (or intercooler 16), a high-pressure turbocharger 18, a charge air cooler 20 (or after-cooling 器20) and exhaust manifold 22 ( Figure 7A-Figure 7B ). As described in more detail below, turbochargers 14, 18, coolers 16, 20, and exhaust manifold 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com