Touching type 3D printed moon lamp and manufacturing method thereof

A 3D printing, touch-type technology, applied in the field of touch-type 3D printing moon lamp and its preparation, can solve the problems of difficult disassembly, carrying, moving, disassembly, and maintenance of the moon lamp, and achieves good sealing, low cost, and connection. solid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to facilitate a better understanding of the present invention, the following examples are used to illustrate, and these examples belong to the protection scope of the present invention, but do not limit the protection scope of the present invention.

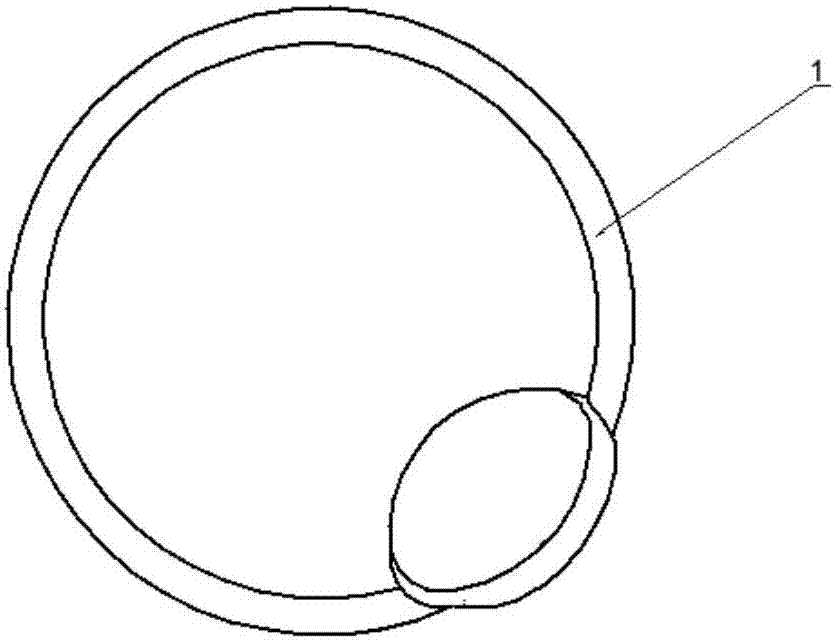

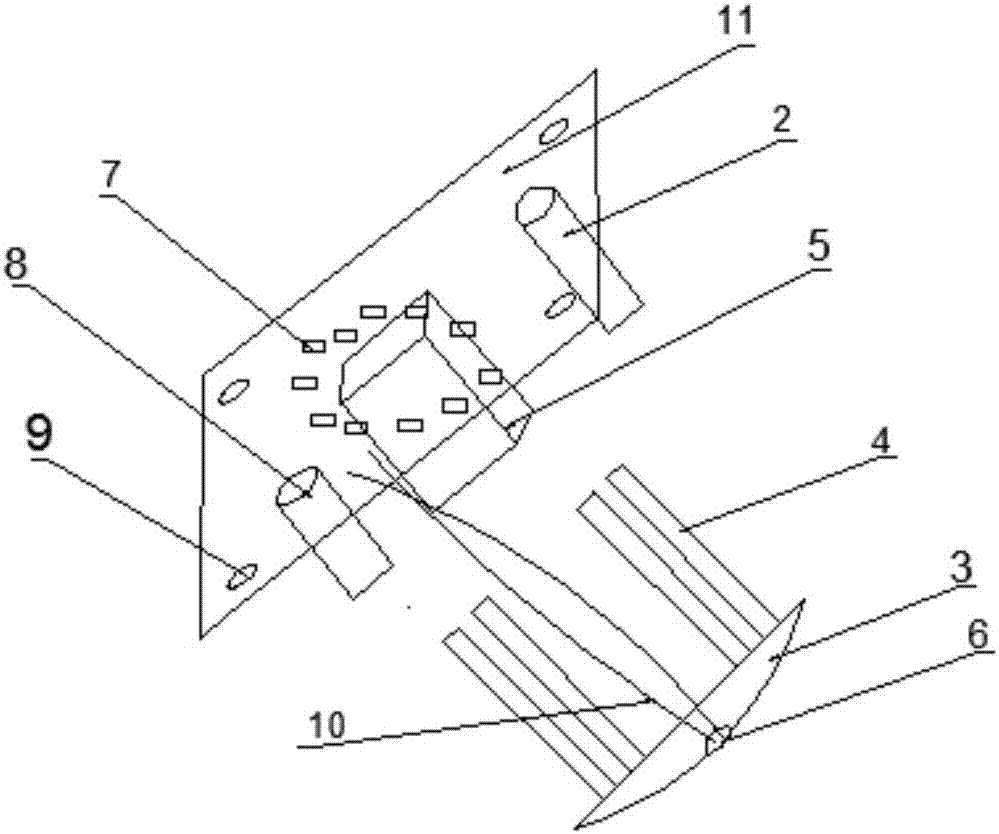

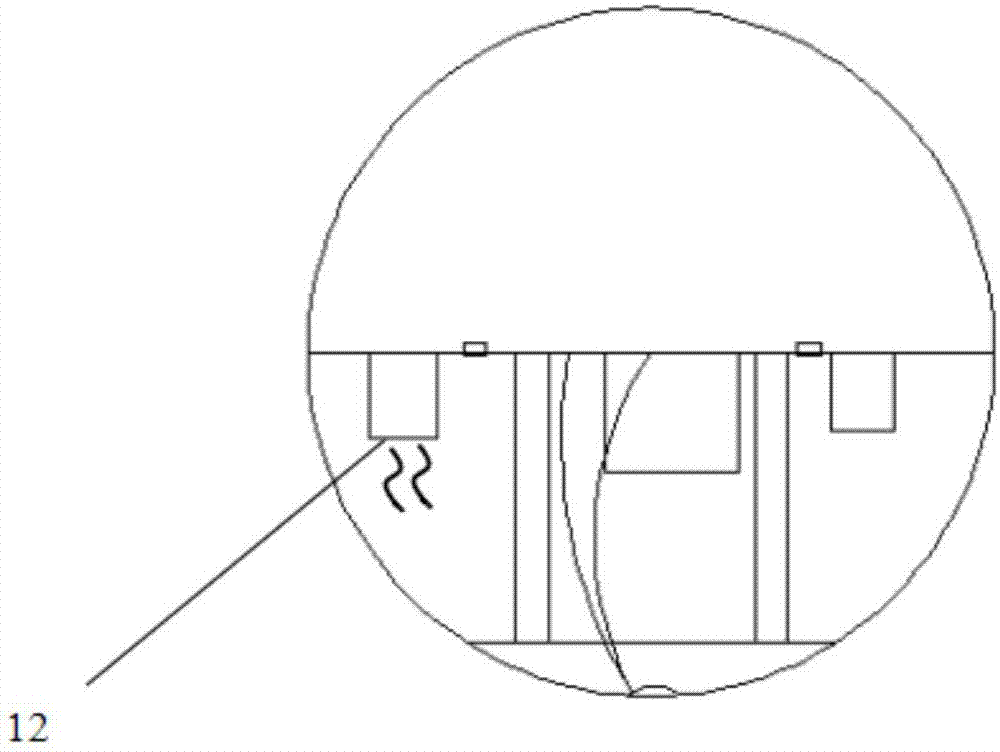

[0031] Such as Figure 1-3 As shown, the touch-type 3D printing moon lamp includes a lampshade 1, a capacitor a 2, a lampshade base 3, a connecting support stud 4, a battery 5, a touch piece 6, an LED lamp body 7, a capacitor b 8, bolt holes 9, Wire 10, circuit board 11, wireless charging module 12, the upper part of the 3D printed moon lamp is a lampshade 1, the lower part is a lampshade base 3, a circuit board 11 is arranged inside the lampshade 1, and a capacitor a2 is arranged on the circuit board 11 , battery 5, LED lamp body 7, capacitor b 8, bolt hole 9, said capacitor a 2, capacitor b 8 are all provided with a wireless charging module 12, said lampshade base 3 is provided with connection support stud 4, to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap