A Gradient Atomization System

An atomization system and gradient technology, applied in the field of stage lights, can solve the problems of light blocking, reflection of atomization components, and affecting the use effect, etc., and achieve the effect of strong atomization, obvious atomization effect, and uniform atomization level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

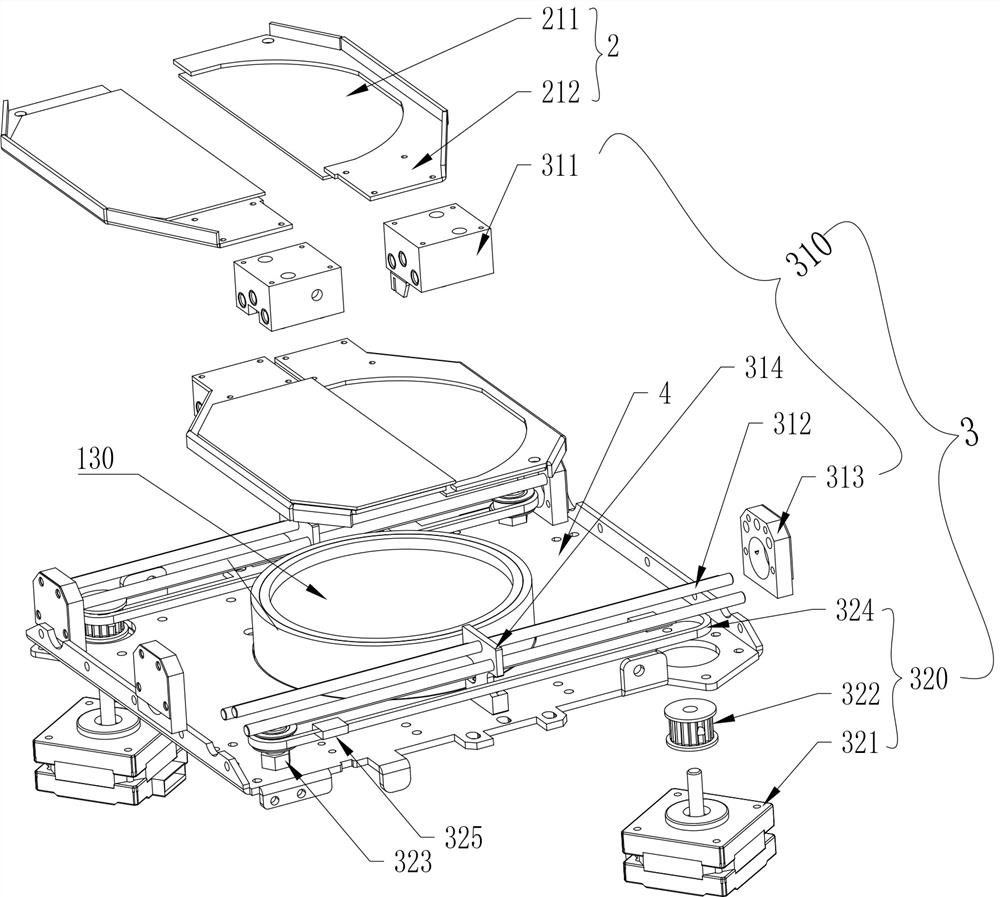

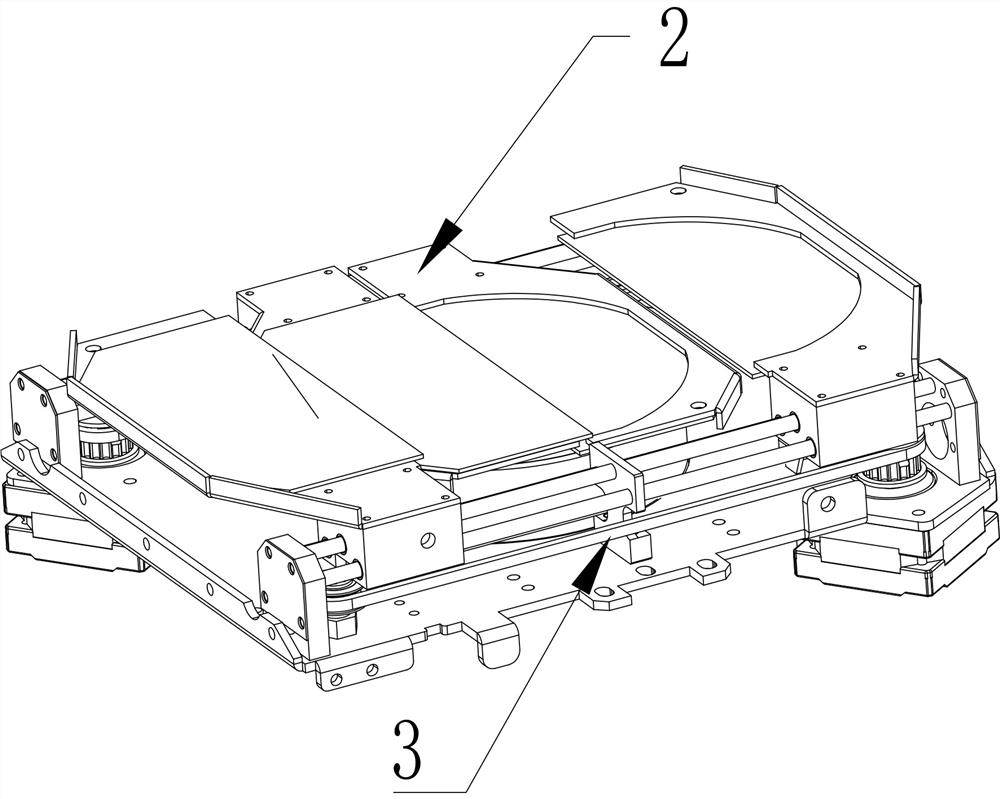

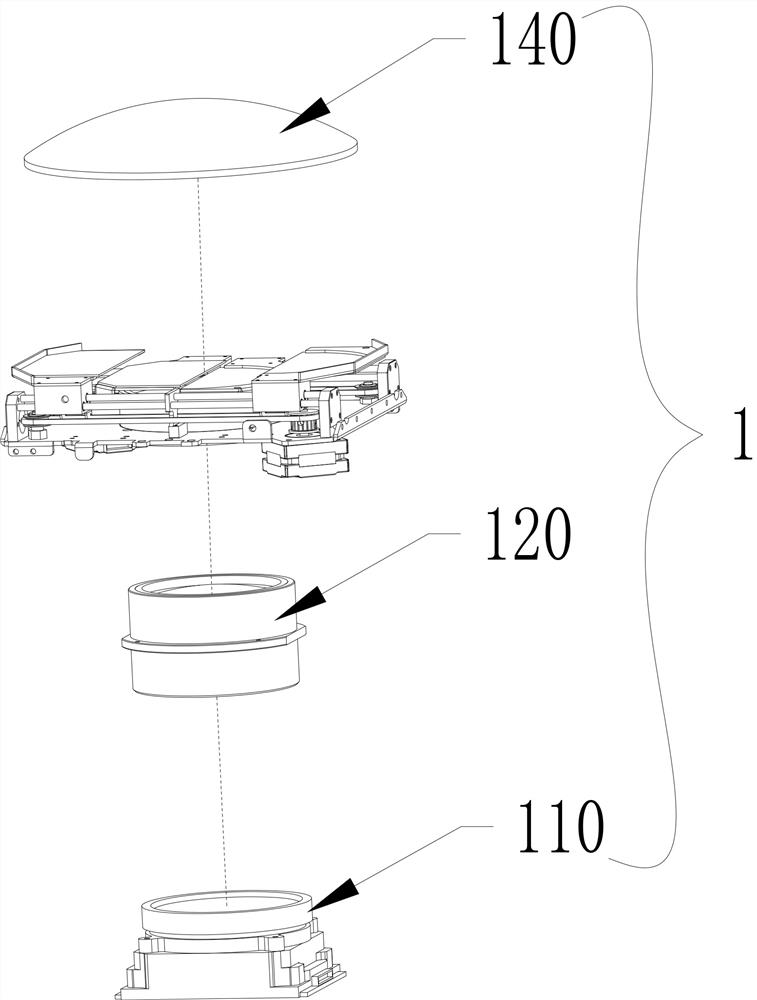

[0029] Such as Figure 1 to Figure 3 As shown, a gradual atomization system includes a light processing mechanism 1 arranged along the main optical axis of the beam, an atomization mechanism 2 perpendicular to the main optical axis of the beam, and a power for outputting power to drive the atomization mechanism to move Mechanism 3, the power mechanism 3 is arranged under the atomization mechanism 2, and the atomization mechanism 2 includes two atomization assemblies 210 with opposite or opposite movement directions, namely the left atomization assembly and the right atomization assembly , the left and right atomizing components 210 are arranged on the power mechanism 3 and driven by the power mechanism 3 to perform an opening-closing movement on a plane perpendicular to the main optical axis.

[0030] In this embodiment, two groups of atomizing mechanisms 2 arranged up and down on a plane perpendicular to the main optical axis and two groups of power mechanisms 3 connected to ...

Embodiment 2

[0042] The difference between this embodiment and Embodiment 1 is that the atomizing sheets 211 of the left atomizing assembly and the right atomizing assembly protrude from the mounting plate 212 on opposite sides, and the left atomizing assembly and the right atomizing assembly are staggered by a certain height It is arranged up and down. When the slider 311 drives the left and right atomizing components to make relative motion, the atomizing sheets 211 of the left and right atomizing components are in the closed state when they are on the same plane parallel to the main optical axis. At this time, the left and right two The two atomizing sheets will continue to move forward relative to each other until they touch the limiter 314. During this process, the left and right atomizing sheets are in a partially overlapping state, that is, the left and right atomizing sheets are in a state perpendicular to the main optical axis. The open-close-overlap movement of the plane can reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com