Inspection correction method of visual inspection device

A technology of visual detection device and correction method, which is applied in the field of visual detection, can solve the problems of inability to correct the position of materials or products, great influence on the recognition of objects, and inability to extract reference templates, etc., achieving high degree of automation, good detection effect, and high speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings.

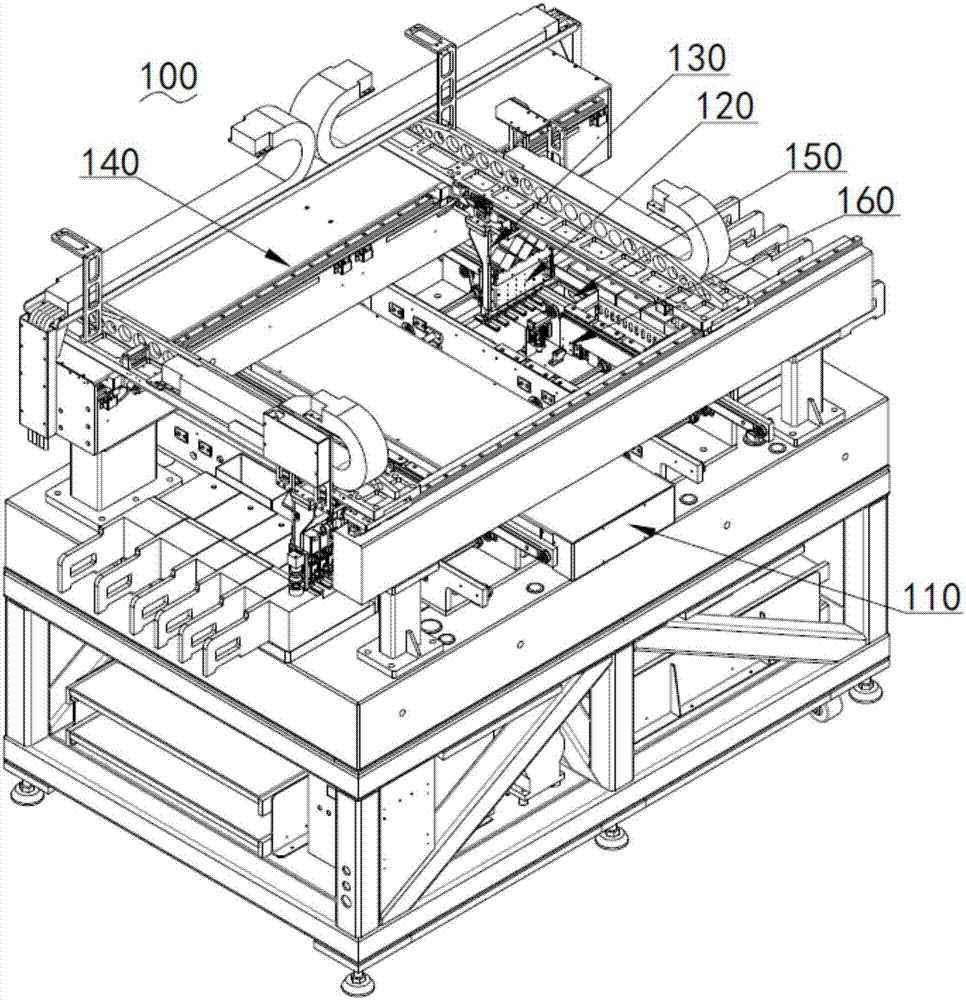

[0044] Such as figure 1 Shown is a perspective view of the visual detection device of the present invention.

[0045]A detection and correction method for a visual detection device, the visual detection device 100 includes a control system 110, a material suction module 120, a correction module 130, a transmission module 140, a detection module 150 and a fixture module 160, and the control system 110 is used to control The operation effect is to achieve the effect of absorbing and placing materials through the suction module 120, to achieve the effect of position correction through the correction module 130, to achieve the effect of driving and transmission through the transmission module 140, to achieve the effect of shooting and detecting materials through the detection module 150, and to achieve the effect of shooting and detecting materials through the jig The eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com