Self-levelling portable truck scale

A portable, self-leveling technology, applied in the field of truck scales, can solve the problems of increasing and decreasing measurement costs, limiting the use range of portable truck scales, etc., and achieves the effects of accurate weighing, convenient and flexible movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

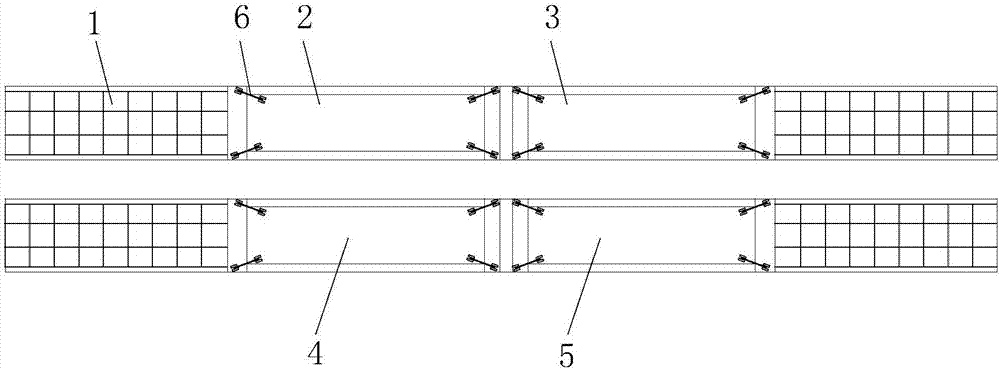

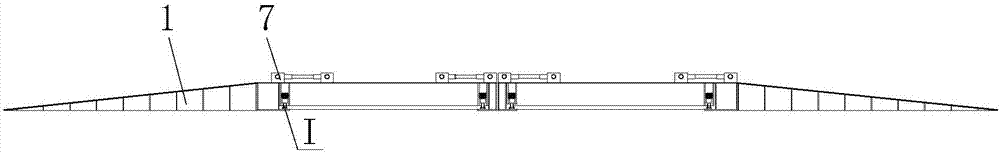

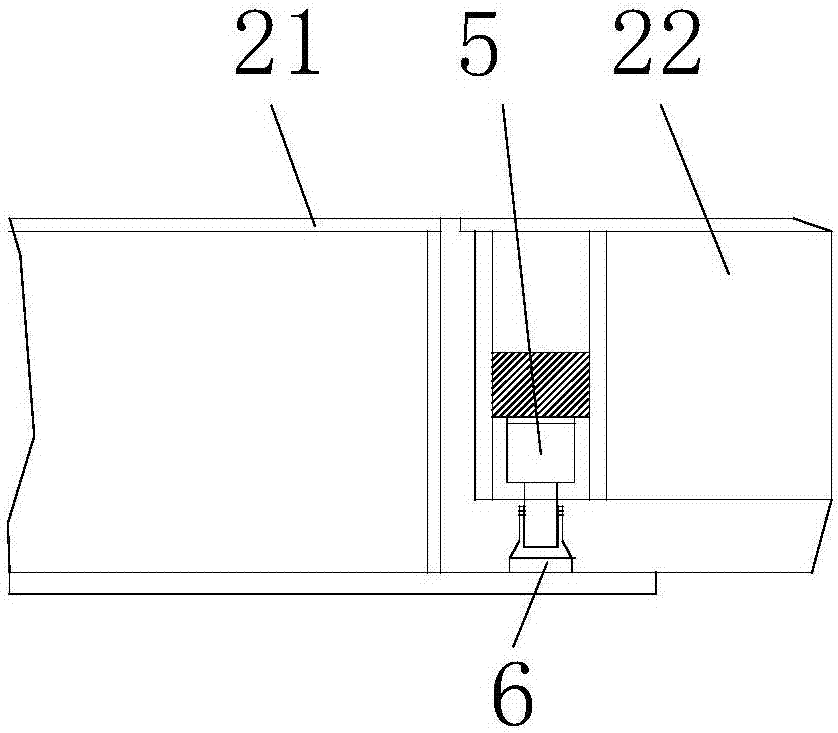

[0018] refer to Figure 1-3 As shown, a portable truck scale with a self-leveling function, including a guide slope 1, a balance board 2, a pressure sensor 5, a hydraulic leveling device 6, a control box, a computer, a printer, the guide slope 1 and a balance board The quantity of 2 is 2, and the described leading slope 1 is arranged at both ends of the balance plate 2, and the two balance plates 2 are arranged in parallel; the connecting rod 3 is used between the described balance plate 2 and the leading slope 1 connected, the balance board 2 includes a frame 21 and a weighing platform 22, the weighing platform 22 is fixed on the frame 21, and the four corners of the lower end of the weighing platform 22 are fixed with a pressure sensor 5 and a hydraulic leveling device 6, so The pressure sensor 5 and the printer are connected to the computer, and the hydraulic leveling device 6 is connected to the control box.

[0019] As a preference, a limiting device 4 is provided on the...

Embodiment 2

[0021] refer to Figure 1-3 As shown, a portable truck scale with self-leveling function includes a guide slope 1, a balance plate 2, a pressure sensor 5, a hydraulic leveling device 6, a control box, a computer, a printer, and a vehicle number identification device. The number of the slope 1 and the balance board 2 is 4, the four balance boards 2 form a group, and the two groups are arranged in parallel, and the four leading slopes 1 are respectively arranged in two groups Both ends of the balance board, the balance board 2 and the leading slope 1 and the two balance boards are connected by connecting rods 3, the balance board 2 includes a frame 21 and a weighing platform 22, and the weighing platform 22 Fixed on the frame 21, the four corners of the lower end of the weighing platform 22 are fixed with a pressure sensor 5 and a hydraulic leveling device 6. The pressure sensor 5 and the printer are connected to the computer, and the hydraulic leveling device 6 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com