Arm rack type full-hydraulic automatic concrete loading, stirring, conveying and distributing all-in-one system

An automatic feeding and concrete technology, applied in mixing plants, cement mixing devices, liquid batching supply devices, etc., can solve the problems of high labor intensity, high transportation costs, inconvenient operation, etc., and achieve reduced labor intensity and high degree of automation. , mobile flexible and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

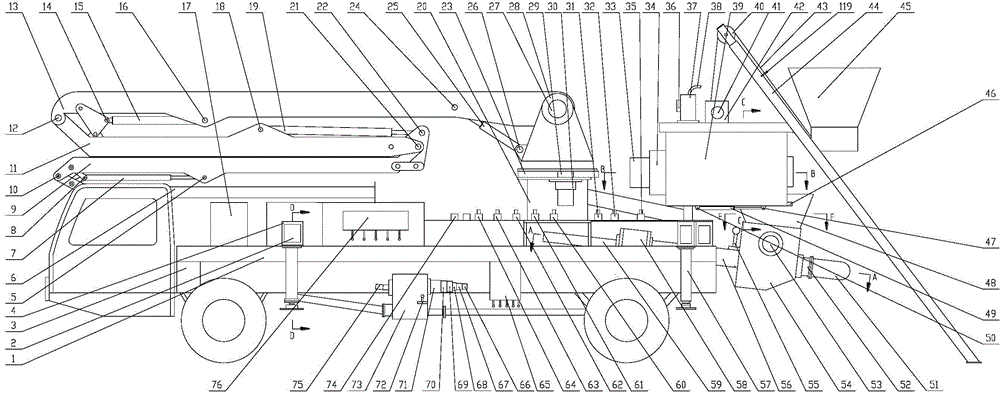

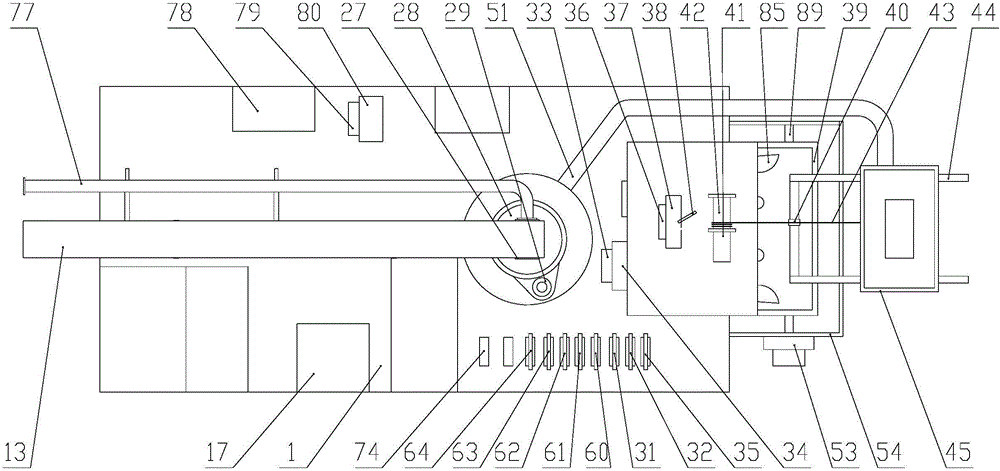

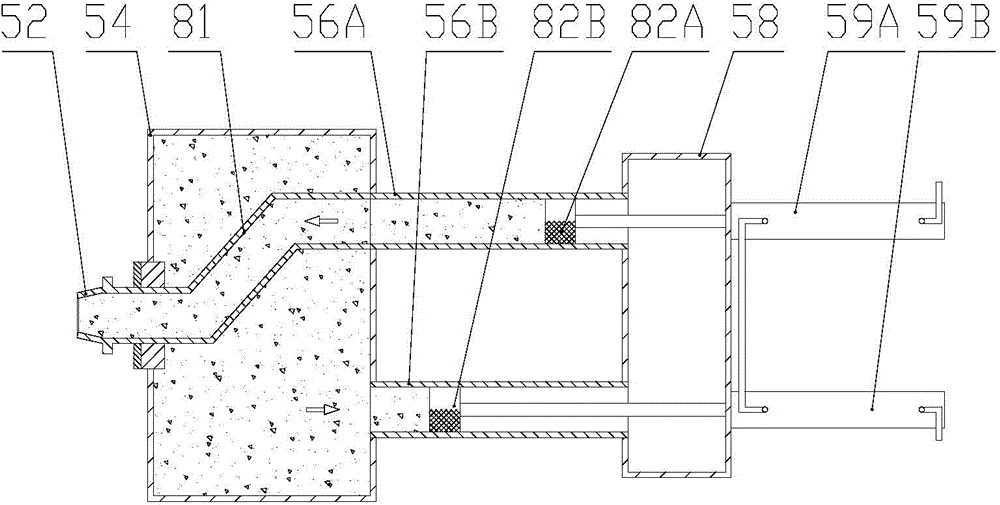

[0030] Attached to the invention Figure 1-11 The tags are as follows:

[0031] 1 is a frame, 2 is a telescopic square tube (including 4), 3 is an automobile chassis, 4 is a fixed square tube (including 4), 5 is the pin shaft 1 of the fourth joint oil cylinder, and 6 is the fourth joint arm, 7 is the fourth arm oil cylinder, 8 is the fourth arm oil cylinder pin II, 9 is the third arm, 10 is the fourth arm pin, 11 is the second arm, 12 is the second arm pin , 13 is the first section arm, 14 is the second section arm oil cylinder pin II, 15 is the second section arm oil cylinder, 16 is the second section arm oil cylinder pin I, 17 is the oil tank, 18 is the third section arm oil cylinder pin Axis I, 19 is the oil cylinder of the third section arm, 20 is the slewing support seat, 21 is the pin shaft of the third arm frame, 22 is the pin shaft II of the oil cylinder of the third section arm, 23 is the slewing bearing, and 24 is the pin of the oil cylinder of the first section arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com