Dustproof ship deck surface treatment device

A technology for surface treatment device and ship deck, applied in the field of ship transmission, can solve the problems of uneven surface of ship deck, affecting the quality of cladding coating, and reducing ship safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

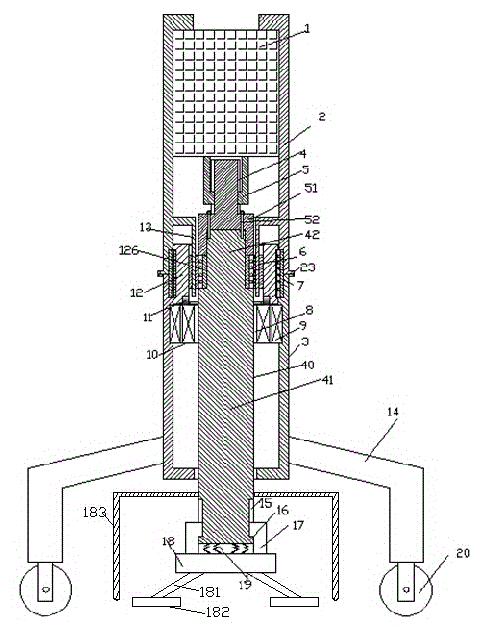

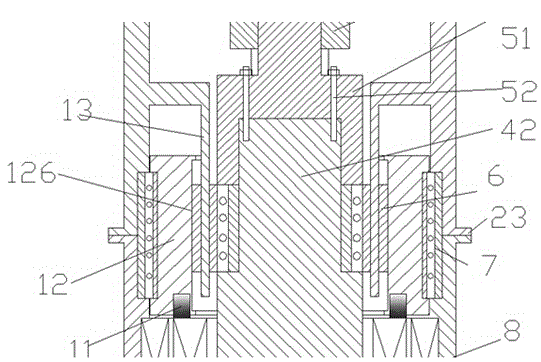

[0014] Combine below Figure 1-2 The present invention will be described in detail.

[0015] A dust-free ship deck surface treatment device for grinding the deck surface, comprising an upper shell 2 and a lower shell 3, the upper shell 2 and the lower shell 3 are fixed by respective flanges 23 connected together; the lower part of the lower housing 3 is fixedly connected with a roller arm 14, and a roller 20 is installed on the roller arm 14;

[0016] A grinding drive motor 1 is installed on the upper part of the upper housing 2, and the grinding drive motor 1 is power-coupled with a spline sleeve 5, and the spline sleeve 5 cooperates with the spline shaft on the upper part of the spline shaft connector 4. The lower part of the splined shaft connector 4 is a connecting sleeve, the recess of which accommodates the upper small diameter portion 42 of the grinding head drive shaft 40 and the connecting sleeve is connected with the grinding head drive shaft through a longitudinall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com